I implemented my first PLM system in 2002, at that time it was called Engineering Data Management, its name SMARTEAM. Since then I implemented pairs of dozens of PDM, PLM and battled against competitors like Arena PLM, Windchill, and Teamcenter at that time desktop and on-premises was king while Arena was cloud web browser-based. Many ERP Integrations in between. From projects with CPQ, where you configure, price, and quote, streaming data flows from sales BOMs merge with Engineering BOMs and produce a manufacturing bill of materials with routings and operations to send to million-dollar ERPs for scheduling and planning. I have done “replace Excel” battles too. And these were the hardest. Replacing Excel was called “Transform”, a fancy name for it to change people’s old ways.

I have written this article because I found the greatest way to make it happen and how to replace Excel for Bill of Materials and product structures.

A New Generation Of Engineers Is Here

Long ago I realized listening to the future generation of engineers and my customers in my house, my daughters, that the cloud is the way to go. There is no local drive just “my data in my account, Dad, what do you mean USB pen?”

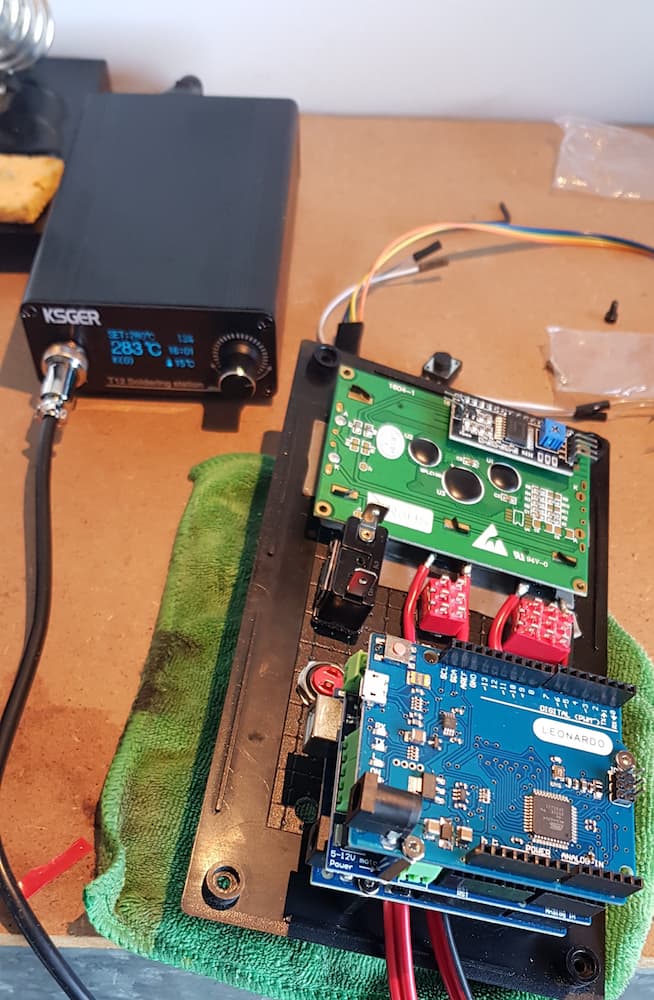

That was what my youngest said for scratch or when I tried to influence Arduino programming for her to share code. I was using the desktop version, she chose the web interface. Check out some of my maker projects.

If you are a hobbyist there is no need for PLM for makers. Don’t overcomplicate, all you need is a pencil in your ear and a good eye, measure twice.

Speaking of PLM there are multiple PLM products (Arena vs. Windchill vs. Teamcenter), and here is what makes OpenBOM different:

Ease of use

This is very important to get traction outside the Engineering department, as other users might not have the same computer skills or patience to use complex interfaces. User adoption is key for a successful digital data flow between different teams and departments.

OpenBOM Excelish interface is very easy to use. This is what easy looks like:

Complete CAD integration

Complete means supports SolidWorks Configurations or family tables on other CAD, Weldments, Automate Part Numbers, save Properties from and to CAD, Support all SolidWorks or Onshape BOM mechanisms like exclude from BOM and dissolve or hide subassemblies, besides STEPS and PDFs also support the extraction of flat patterns of sheet metal components to DXF files for laser cutting. Complete multiCAD like SolidEdge, Fusion 360, Inventor, Onshape, and Altium. More info here

This is what complete looks like:

“Speedboat” MRP functions

These functions can help you to stay away from “Titanic” ERPs for longer. Most PLM systems don’t have material resource planning functions like inventory control, requests for proposals and purchase orders, or a clean differentiation between a PBOM – Planning BOM or Production BOM vs. a “BOM View” with some filters. Companies then move to buy expensive ERP systems and create another Silo, another disconnected system, if you can stay on the same platform then you gain efficiencies, accuracy, and agility.

Conclusion

When comparing systems make sure you have the requirements set, and understand the cost of ownership and cost of implementation, if you are trapped on Excel BOMs with errors on wrong quantities or want to harness the power of your CAD data, wait no longer, you are making the problem escalate to new dimensions.

Check OpenBOM Customer Stories and User Reviews to explore firsthand what customers do with OpenBOM and how they compare OpenBOM to other PLM platforms.

Now is the best time to Act. Make it happen.

REGISTER FOR FREE and start a 14-day trial to explore how OpenBOM can help you.

Best,

Pedro Branco

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.