Earlier this week webinar about one of the most complex BOM management topic – interchangeable revisions and part numbers.

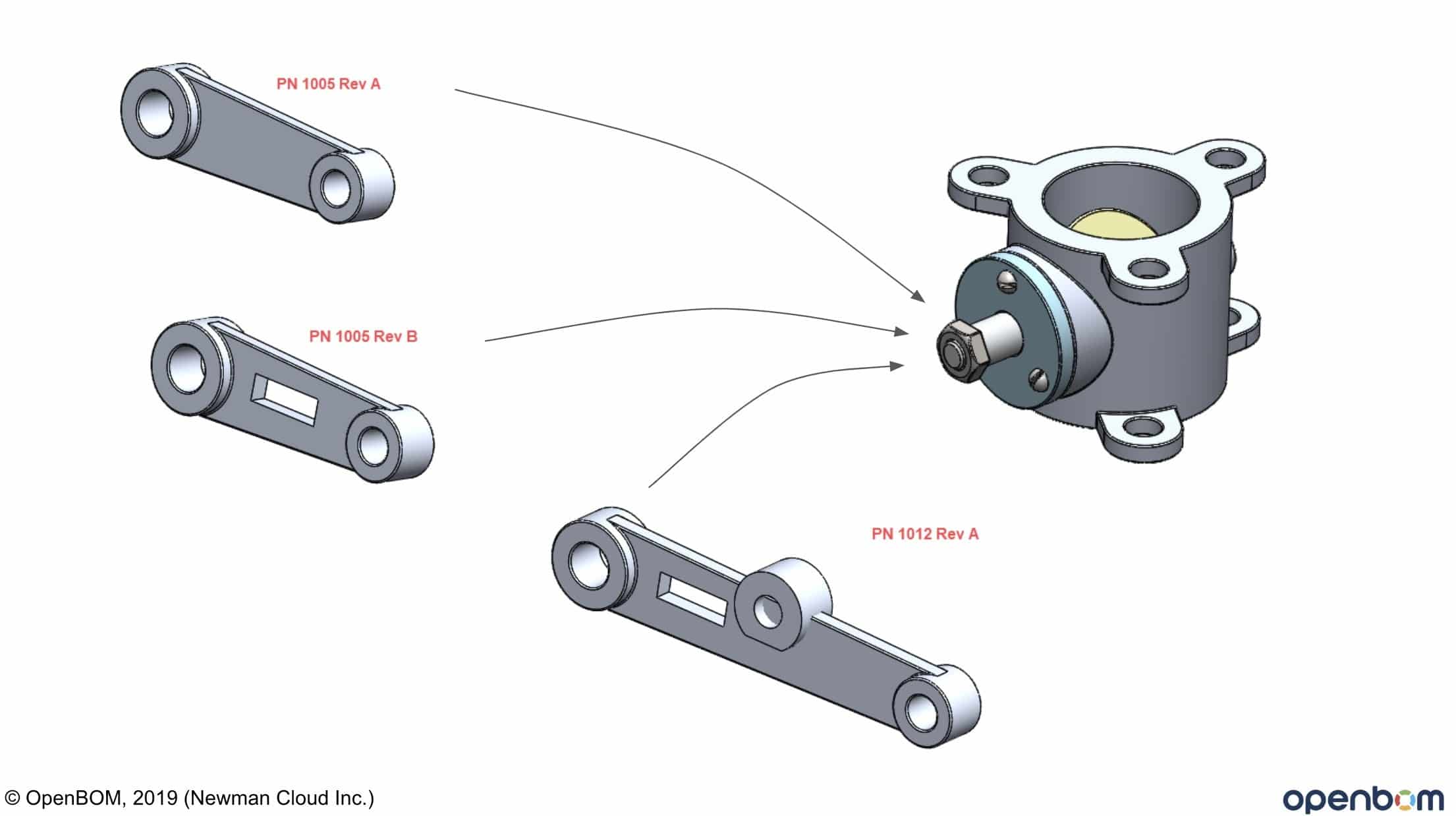

Managing part revisions is hard and BOM revisions are even harder. How and when is a change just a change and when is it a new part? Earlier this week, we explained important use cases of interchangeable revisions in a Bill of Materials and how does Form, Fit and Function effect BOM behavior.

If you’re interested to learn about the history of interchangeable parts, check this article

In the mid-18th century, the French gunsmith Honoré LeBlanc suggested the gun parts be made from standardized patterns, so that all gun parts would follow the same design and could be easily replaced if broken. LeBlanc was not alone in imagining the potential value of this concept; an English naval engineer Samuel Bentham had earlier pioneered the use of uniform parts in the production of wooden pulleys for sailing ships. LeBlanc’s idea didn’t catch on in the French gun market, however, as competing gunsmiths saw clearly the effect that it would have on their craft. In 1789, Thomas Jefferson, then serving as American minister to France, visited LeBlanc’s workshop and was impressed by his methods. Despite LeBlanc’s efforts, however, it would be left to another man to fully introduce interchangeable parts into the American — and later the international — weapons industry.

Here is a video recording of the webinar:

And here is a slide deck of the webinar

WEBINAR: Interchangeable Part Revisions in BOMs. Is this a Revision or a New Part? from Oleg Shilovitsky

Few important guidance related to interchangeability and revisions.

- Life is easier with unintelligent (dumb) part numbers (just numbers)

- If you are using intelligent part numbers never store Rev or other state or phase info in the part number

- Use a BOM management tool like OpenBOM which associates and keeps data with part number (a database, not Excel)

- Use Form, Fit and Function as a design principle. Enforce it.

- Decide who and how Revisions will be rolled up through the assembly structure and when to stop. Revisions cost money, do not Rev the battleship! (RtB2)

- Keep track of Rev in the planning BOMs so supply folks know what to buy

- Create a Manufacturing View of your BOM without Rev

- Do NOT put Rev in the assembly BOM or on the drawing. With F3 parts are interchangeable, if they are NOT, get a new part number. (we will cover BOMs on drawings in more details in another webinar)

Conclusion.

An agreement about how to manage interchangeable parts in the company is one of the fundamental to have product development and manufacturing process to flow in a smooth way. If you missed that, you will be suffering from too many revisions or under-traceability. Spending some time on interchangeability planning can save many future troubles with manufacturing, suppliers, and customers.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.