At OpenBOM, we are committed to helping our customers in a variety of ways. One of them is to share the knowledge and experience we have in engineering software as well as in a variety of manufacturing disciplines.

Today, I’m super excited to introduce to you Jared Haw, who joined our team several months ago in the capacity of Business Executive. Jared has extensive experience in manufacturing working in a variety of industries and companies in the manufacturing domain in the United States and China. Jared has deep knowledge in contract manufacturing and he will be sharing his knowledge in OpenBOM’s blog.

Today, I’m delighted to share Jared’s personal story. Stay connected with us and follow future stories about Contract Manufacturing from Jared Haw.

Introducing Jared Haw

My story is not fascinating but it is different. I was never meant to be the president of a factory manufacturing consumer goods and consumer electronic products in China…. But things just have a way of working themselves out.

I graduated with an economics degree from the University of Mount Union. During my time I studied in both India and China. Upon returning from China, I decided that after I graduated, I

would move to China and see what I could make of myself there…. As you could see, I didn’t have much of a plan.

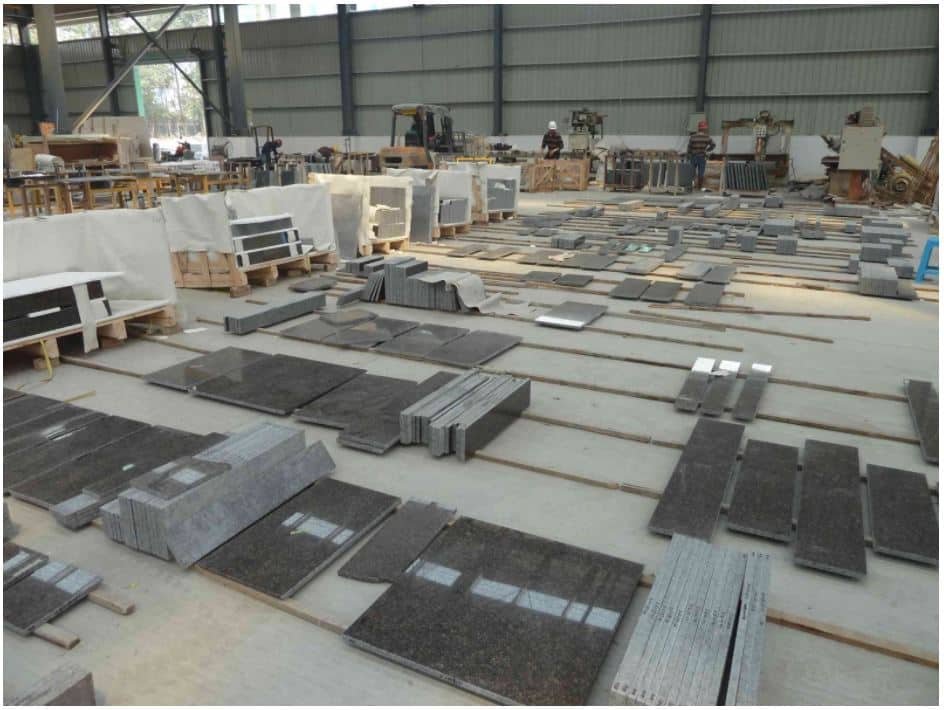

During my early years, I started off at a family friend’s facility in Xiamen, China, cutting and fabricating stone for construction projects (embassies, stadiums, etc). I switched to being in control of QC and production for Spinning and Schwinn Fitness group cycling bikes. After this, I got into the footcare industry, manufacturing insoles, and other footcare and wellness-related products.

Then, I landed a contract manufacturing startup. Our business plan was simple, collaborate with SMBs to streamline the processes from later stage development (DFM) all the way to production. We controlled the supply chain, provided engineering support, managed their production, and assembled everything in-house. And as we grew, we re-invested into our assembly services and in-house production lines, such as a CNC, stamping and lathe.

One thing I knew had to be done in order to grow my business was to improve the way our staff and clients communicated with each other. This does not mean having more phone calls and emails. We were on the phone too often and sending too many emails. This was not efficient and set a low cap of how many projects one could manage.

What I was looking for was a bit different. As you know, for PM, you do not manage the product, but you manage the individual processes of a part that ends up making the final product. The best way to manage these parts is to manage the BOM. So, I was looking for a BOM management platform that would also allow for collaboration (both parties can add part drawings, specifications, etc) an intuitive ECO process and some other features.

Our solution was OpenBOM

Our final results were a more streamlined process from the later stage development to production. Also, our clients could just create purchase orders and send us over the exported version in PDF. Another great thing we found was that we could easily transition from our clients engineering BOM (EBOM) and create the manufacturing BOM (MBOM).

In the eyes of our clients, it was great as well to make RFQ packages. Usually it takes days to create this. However, with everything on the cloud, you just need to export the BOM into Excel format and all the specifications will have links to the Drive and that’s it, you have your RFQ package. As a CM, this isn’t great for us as they could be taking their business elsewhere but looking at it from our clients standpoint, it was great.

Conclusion

I’m looking forward to sharing my experience in Contract Manufacturing with you via our OpenBOM blog. I will speak about what is going on in the minds of contract manufacturers, how you should be leveraging them and more.

So, if you are working with a CM and want to either improve your relationship with them or your overall process (such as QC, lead time, pricing or other related issues) I’m sure you will find a good portion of useful information here.

Please let me know what specific contract manufacturing topics you want me to focus on.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.