Manufacturing companies are facing substantial challenges coming from multiple sources – product complexity, supply chain shortages, competition and cost pressures, innovation, and speed. Looking ahead, data is a strategic asset that all manufacturing companies need to figure out how to use. Companies are producing huge amounts of data, yet need to figure out how to manage it, how to make it useful, and how to turn it into a strategic asset that can help them operate in a much more optimal way, optimize the design to manufacturing loopback, create new and innovative business models and become data-driven organizations.

Manufacturing Challenges

Companies’ stakeholders are under pressure to do more in less time. They are also caught between competing constraints, according to Lifecycle Insights’ Engineering Executive’s Strategic Agenda. Fifty-three percent of the study’s respondents selected “satisfying target requirements, either from customers or competitors” as a top-two development challenge. Forty-five percent also cited “keeping up with development schedules” as a top-two challenge.

The pressure to do more with less applies equally to the creation, iteration, and management of bills of materials (BOM). The BOM is a critical tool throughout the product development lifecycle. Engineers develop the BOM. Manufacturing uses the BOM to define production processes. It then forms the basis of the request-for-quote processes. The services department then uses the BOM to maintain products in the field. At every stage, each functional team tweaks and modifies the BOM for its own purposes. During the chaotic world of product development, these teams need a BOM that they can rely on. Everyone needs to use a single source of truth for the BOM.

Chad Jackson, the CEO and Chief Analyst of Lifecycle Insight shares his perspective on how manufacturing companies are managing data and processes today – from Excel spreadsheets to complex PLM / ERP environments. Both extremes bring some advantages, but can easyily become a point of big failure.

Excel vs Enterprise Systems

Watch the video in which Chad Jackson speaks about the management of the Bill of Materials using Excel spreadsheets.

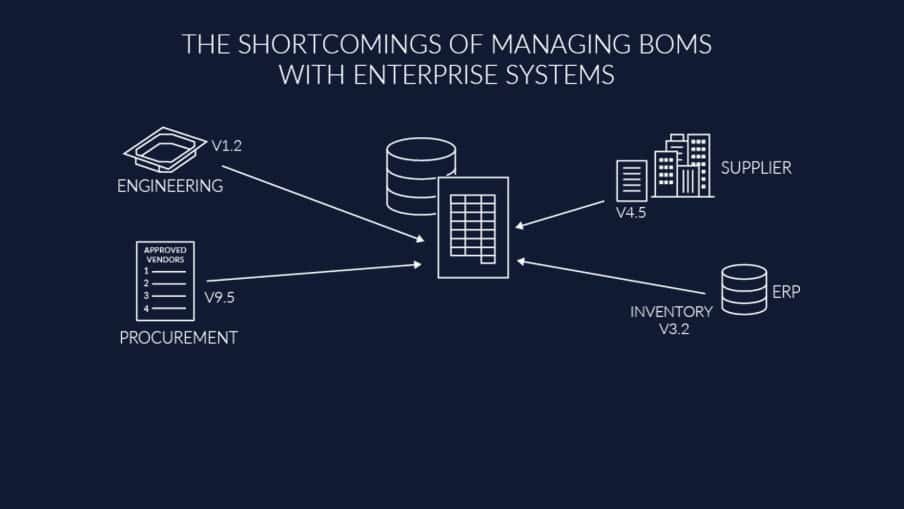

In another video, Chad speaks about what role enterprise systems (PLM/ERP) should play in BOM management, what are challenges of enterprise systems, and how to prevent them from happening.

White Paper – Managing Bill of Materials

There must be a better way! Download Our Lifecycle Insight White Paper and learn more about how to manage Bill of Materials in modern manufacturing and avoid the pitfalls of both messy Excel spreadsheets and complex enterprise systems.

Conclusion

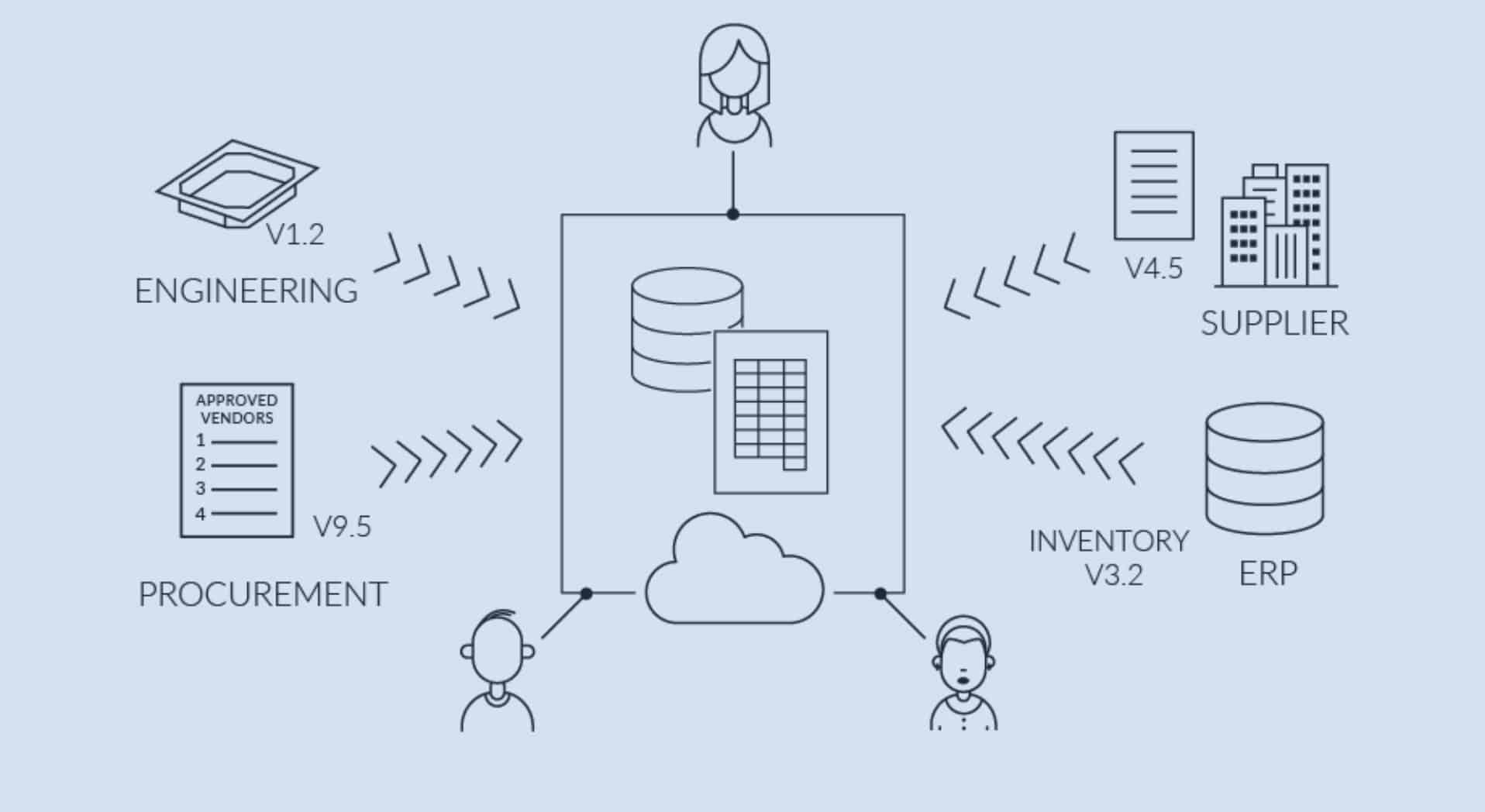

A BOM is a critical deliverable in the product development process. However, traditional solutions for managing a BOM lack flexibility to connect disparate systems and teams.

Stakeholders are under significant pressure to do more with less while working under conflicting constraints. Spreadsheets provide flexibility but struggle to keep pace with changes to the BOM. Enterprise systems lack flexibility but aid collaboration, connecting disparate systems and teams. Cloud-based tools are now available, addressing these challenges and bringing the best of both worlds. Check the Lifecycle Insight paper to learn more.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.