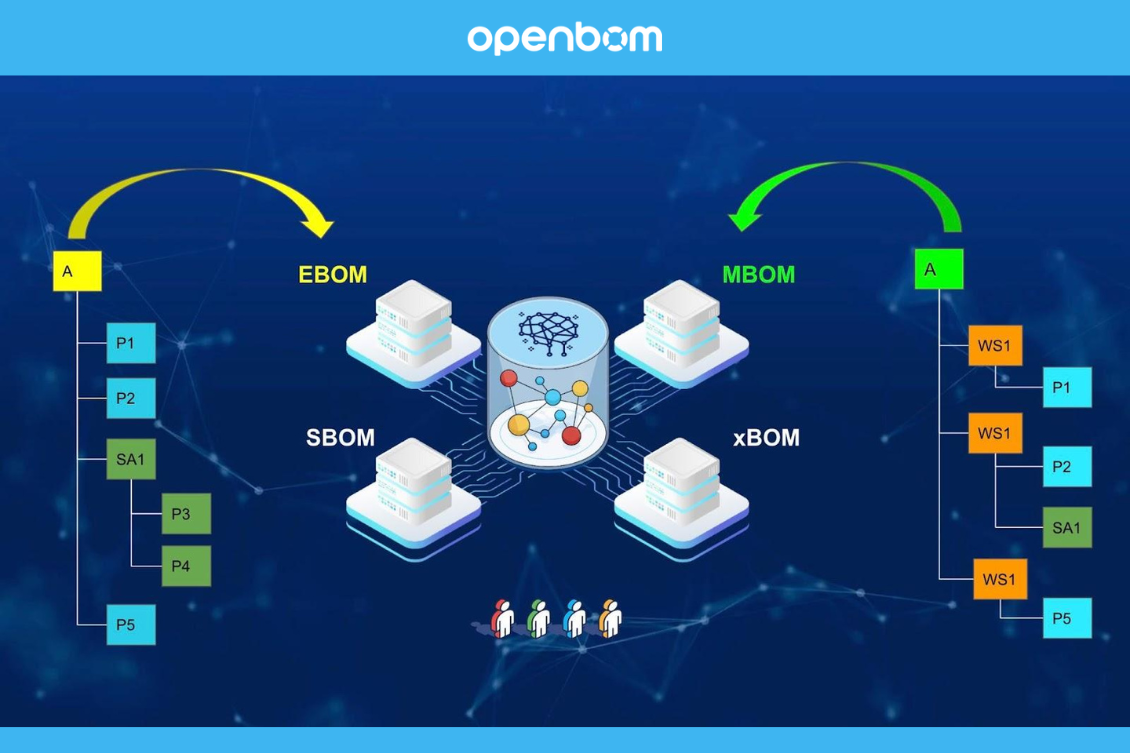

OpenBOM is excited to announce significant enhancements for our customers with the introduction of the ability to manage xBOM (BOM types). This new capability will empower users to model product structures at various lifecycle stages, catering to multiple purposes and different departments. For instance, typical use cases include EBOM (Engineering Bill of Materials) for engineering, MBOM (Manufacturing Bill of Materials) for manufacturing, and SBOM (Support Bill of Materials) for support and maintenance.

The purpose of xBOM is to provide a comprehensive view of the product structure, adaptable to the specific needs and functions of various teams within an organization. By enabling detailed and customized BOMs, OpenBOM ensures that each department can efficiently manage their respective tasks, leading to improved collaboration and streamlined processes across the entire product lifecycle.

The vision of OpenBOM is to support multi-view xBOM architecture. Check one of my earlier blog articles – Multi-View BOM and see the CIMdata slide.

In line with OpenBOM’s commitment to innovation, we are proud to simplify and democratize the adoption of xBOM. Traditionally, such capabilities were only accessible through enterprise PLM platforms. However, OpenBOM breaks this barrier by bringing cutting-edge technology and an enhanced user experience to xBOM management. Our platform now makes these advanced features accessible to companies of all sizes, fostering greater efficiency and collaboration.

With this new service, OpenBOM continues to lead the way in revolutionizing product data management, ensuring that our customers have the tools they need to succeed in a competitive market.

BOM Types: Product Lifecycle, Multiple Structures

BOM types are essential for managing multiple product structures derived from the same items. Examples of these BOM types include the Engineering Bill of Materials (EBOM), Manufacturing Bill of Materials (MBOM), and Support Bill of Materials (SBOM). Each BOM type serves a unique purpose and caters to different stages of the product life cycle and various departments within an organization.

By introducing xBOM, OpenBOM significantly expands its capability to offer a robust and flexible infrastructure for managing data across multiple product lifecycle stages. This new feature allows companies to seamlessly transition from engineering to manufacturing and onto support and maintenance, ensuring that each department has access to the specific information they need to perform their tasks efficiently.

One of the critical goals of implementing xBOM was to maintain simplicity. OpenBOM achieves this through a multi-view approach, enabling the definition of multiple “structures” by creating various BOMs all connected to the same top assembly part number. This approach allows for the virtual management of multiple product representations using the same items defined in catalogs.

By doing so, OpenBOM provides a streamlined and intuitive way to manage complex product data, ensuring that all relevant information is easily accessible and up-to-date across different stages of the product lifecycle. This innovative solution not only enhances data accuracy but also promotes better collaboration and communication between departments, ultimately leading to more efficient product development and maintenance processes.

Getting Started with BOM Types Setup 101

Let’s discuss how to start using OpenBOM’s new BOM type functionality. To start with BOM types, the admin of an OpenBOM account must configure BOM types. This is an admin function and needs to be done before someone in the team will be able to create a BOM. Please note, BOM types are only available for OpenBOM Company Subscription level.

Setting Up Multiple BOM Types using Admin

Getting started with managing multiple BOM types in OpenBOM is a straightforward process, thanks to the intuitive admin interface. To set up different BOM types such as EBOM, MBOM, and SBOM, follow these steps.

Access the Admin Panel: Log in to your OpenBOM account and navigate to the Admin dashboard <BOM Types>.

Create New BOM Types: In the Admin Panel, select the option to create new BOM types. You can name each BOM type according to its specific use case (e.g., EBOM for engineering, MBOM for manufacturing, SBOM for support).

Once you are done with BOM Types, users of the company:

Defining Templates for Each BOM Type

To streamline the process and maintain consistency, you can define templates for each BOM type. This optional step allows you to pre-configure the structure and content of your BOMs, ensuring that every new BOM created adheres to the same standards.

BOM Template Creation is a simple process that requires you first to create a BOM, which will include all attributes based on the used catalogs and additional instance attributes. Once it is done, you can save it. We recommend creating as many BOM Templates as needed, so you will always be creating BOMs in a consistent manner.

Define Item Types and Catalogs: Although creating catalogs is a flexible process, we recommend you create all catalogs you need for each Item Type you plan to use. It will allow you to finalize data model creation before getting to the BOM model and BOM type definitions.

Modifying BOM Temples. To modify the template, we recommend you to follow these steps. To create a BOM from the template you need to change. Modify the BOM (attributes and catalogs). Save the template with the same name.

Create, Edit, and Switch BOM Types

Once you have set up your BOM types, editing and switching between them is simple. OpenBOM keeps the same style of working with Bill of Materials you’re already familiar with. However, the new “BOM Type” functionality introduced changes in the create BOM catalog and also introduced a new element of the user interface in BOM editing, where used, and some other commands.

Create a new BOM:

BOM create dialog has changed and now requires you to select the BOM Type (keep in mind if you didn’t now define additional BOM types, the user interface remains the same.

Opening a specific BOM Type

Multiple BOM types can be connected to the same item. Therefore once you select an item and it has multiple BOM types defined, the OpenBOM user interface will allow you to open each specific BOM type individually.

Editing and switching Between BOM Types:

A simple idea behind OpenBOM BOM Types implementation is that each BOM type defined for a specific Part Number (Item) can be edited independently. This means that you need to follow the BOM Type (new) selection control to define with BOM type you’re editing (Keep in mind that you need to create a BOM first)

You edit each BOM independently and you can switch between structures in place.

To switch between different BOM types, use the drop-down menu or navigation panel to select the desired BOM. This feature allows you to quickly view and manage different BOMs without losing context.

Where used query and navigation

OpenBOM “where used” query mechanism is adapted to support different BOM types. You can see them now when you use the “where used” command and you can navigate to a specific BOM type.

Can I restructure multiple BOMs independently?

Yes, you can restructure multiple BOMs independently. Each BOM type can be customized and adjusted to fit the specific requirements of its intended use. This flexibility ensures that the engineering team can focus on the technical details within the EBOM, the manufacturing team can optimize the MBOM for production efficiency, and the support team can maintain an accurate SBOM for maintenance purposes.

Video Intro

To help you get started, we’ve created a comprehensive video introduction that walks you through the process of setting up and managing multiple BOM types in OpenBOM. This video covers everything from initial setup to advanced tips for optimizing your BOM management.

xBOM Multi-View BOM Technological Details

OpenBOM has implemented a multi-view BOM architecture. The architecture of OpenBOM xBOM implementation relies on usage of OpenBOM core data modeling technologies and the usage of graph databases to organize data, connections, and relationships. As such, OpenBOM defines an internal graph model based on defined BOM types and makes it possible to create independent multi-view representations of the BOM based on each individually created structure.

Here is the example of FlashLight BOMs – EBOM and MBOM defined simultaneously.

xBOM- where we are and what is coming?

The current introduction of xBOM service is a first step in the expansion of OpenBOM data modeling and functional capabilities to support multi-view BOM strategy, and the definition of flexible BOM infrastructure to support the full product lifecycle.

The foundation of OpenBOM, graph database, and flexible data modeling schema allows to create and maintain multiple BOM structures. The custom BOM types help you to create different BOM representations – EBOM, MBOM, SBOM, and others (this is custom).

Where used service allows you to see where each item is used (including multiple BOM types).

OpenBOM revision and change management mechanism supports the creation of revisions in multiple BOM types.

But we are at the beginning of our xBOM story. Multiple OpenBOM services will be expanded and extended to provide advanced support to xBOM in the next several releases such as:

- Advanced BOM compare

- Advanced BOM type graph navigation

- Automatic clone of BOM structures between BOM types

- Other enhancements

Conclusion

The introduction of OpenBOM’s BOM types marks a significant advancement in product data management, offering our customers the ability to efficiently manage multiple product structures derived from the same items. With xBOM, users can seamlessly navigate through different lifecycle stages, from engineering to manufacturing to support, ensuring each department has the tailored information they need.

The flexibility and robustness of BOM type definitions within OpenBOM provide a dynamic and adaptable framework. This ensures that every unique requirement of the product lifecycle is met with precision, allowing for better collaboration and streamlined processes across various teams.

At the core of this innovation lies the powerful graph model behind OpenBOM’s multi-view architecture. This model connects multiple BOMs to the same top assembly part number, enabling the virtual management of diverse product representations. This interconnected structure not only enhances data accuracy but also simplifies the overall management of complex product data.

Our commitment to providing a simple and intuitive user experience remains a top priority. The easy-to-use admin interface, coupled with the ability to define templates and independently manage BOM structures, ensures that users can quickly adapt to and leverage the full capabilities of xBOM. Looking ahead, we are excited about future enhancements that will continue to expand and refine these capabilities, further empowering our users to achieve their goals.

In summary, OpenBOM’s xBOM service represents a leap forward in managing product data, combining flexibility, robustness, and simplicity to deliver an unparalleled user experience. We are proud to lead the way in this innovative space and look forward to continuing to support our customers with cutting-edge solutions.

REGISTER FOR FREE and try OpenBOM’s BOM Types today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.