In the world of cloud-based PLM solutions, “multi-tenancy” is a frequently mentioned term. It’s often presented, especially by major PLM vendors, as a feature allowing multiple companies to operate on the same platform online (SaaS). While this is accurate, it barely scratches the surface of what true multi-tenancy entails.

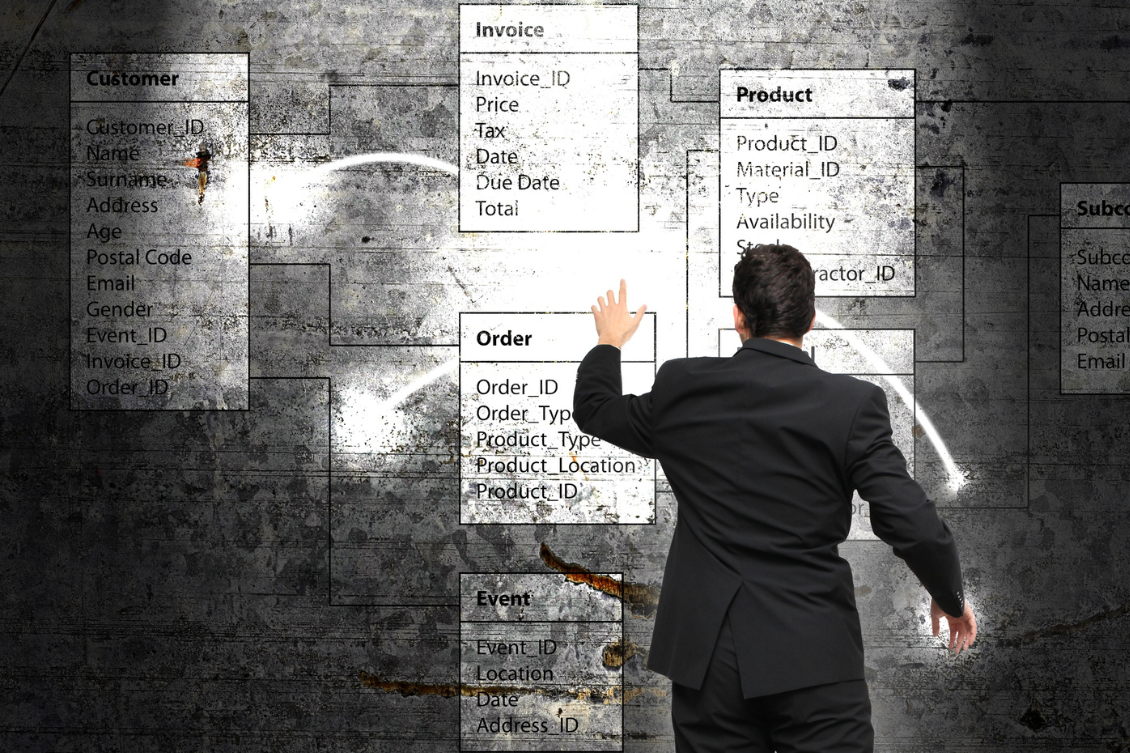

The traditional PLM architecture looks like the following diagram- every company has its own database.

Let me start by bringing you an example everyone is familiar with – Google Docs. You can create a Google Sheet and share it with someone else (everything you need is Gmail). This person can work in the same organization or different organizations. You can be as granular and as flexible as you need to be. Sharing a Google sheet gives cloud flexibility to people using Google Docs.

Let’s bring up the same question in the context of PLM. Ask every vendor that sells you PLM about how to create some data objects (eg, Item or BOM) and share it with another company that is using the same PLM software. For a vast majority of people, you won’t be able to do so.

Before jumping into the details, check the following architecture diagram that shows the landscape of PLM architecture in the context of multi-tenancy.

As you can see above, the upper right segment – multi-tenant data is where you want to go if you desire your modern SaaS PLM to share data between multiple companies and organize a network of manufacturers.

Today, I want to dig deeper into three critical elements of OpenBOM’s multi-tenant data model that set it apart: (1) granularity and flexibility, (2) data sharing, and (3) networking.

1. Granularity and Flexibility

OpenBOM stands out due to its granular and flexible data architecture. Unlike traditional systems that might constrain you to predefined structures, OpenBOM’s data is composed of multiple information pieces – attributes, catalogs, various BOMs, product structures, vendors, orders, and more. This structure enables a high level of customization; you can introduce any data attributes and data objects (such as catalogs and custom objects). Essentially, OpenBOM empowers you to build any data model you require, tailored precisely to your unique business processes. This granularity and flexibility are crucial for creating a system that evolves with your needs, rather than forcing you to adapt to the system.

2. Data Sharing

Data sharing is where OpenBOM truly differentiates itself from other “flexible” solutions. OpenBOM allows you to share BOMs directly with contract manufacturers, facilitating real-time communication. This capability is a significant leap forward compared to most SaaS products that often fall short in enabling seamless, real-time collaboration. With OpenBOM, the barriers that traditionally impede data flow between engineering, manufacturing, and supply chain partners are removed, fostering a more integrated and responsive workflow.

3. Networking

The networking capabilities of OpenBOM’s data model allow multiple companies to collaborate effectively. This feature goes beyond simple data sharing; it enables the organization of processes that flow across multiple organizations. Whether it’s sharing pieces of information, coordinating complex projects, or maintaining individual data boundaries while collaborating, OpenBOM’s networking facilitates a cohesive yet flexible collaboration environment. This interconnected approach ensures that all stakeholders can work together efficiently without compromising the integrity or security of their individual data sets.

How does it work?

From a user perspective, the work is simply by sharing data (manually or automatically) with the right target. This is how it will work and it is as simple as Google Docs. Automatic Team sharing is also possible.

What happens behind the scenes is that OpenBOM introduces a multi-tenant data model that allows data objects to be granularly defined with access control based on object/view levels. In this way, you can share, for example, a specific catalog or data subset based on both a set of properties and a set of filters between two individuals working in different companies. You can think about an OEM sharing a production planning BOM with contract manufacturers, or a vendor making components and sharing what they do with multiple customers. These examples demonstrate how OpenBOM enables building a network of data, helping companies in manufacturing networks share data and operate in a connected way to run their processes

Conclusion

The multi-tenancy of OpenBOM’s data model introduces significant differentiators: the ability to define granular custom data objects, the unparalleled capability to share data across multiple companies in real-time, and the networking functionality that allows organizations to collaborate while maintaining their data boundaries. These elements collectively provide a robust, flexible, and integrated platform that surpasses traditional PLM solutions. The multi-tenant data architecture of OpenBOM allows you to share data and creates use cases that have never been supported by legacy on-prem PLMs and hosted an online SaaS PLMs with single tenant architecture – eg. real-time sharing of catalogs providers from component vendors to OEMs, direct access to quotes by multiple contact manufacturers and many others.

Explore how OpenBOM can transform your data management processes by registering for FREE today and discovering its powerful capabilities firsthand.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.