Data is one of the most valuable assets for any product development and manufacturing company in the world. Unfortunately, for many companies, the data is an afterthought. Companies are using CAD and other design systems to create products, but later manage these files and create Excel spreadsheets to pass requests to ERP systems. A significant amount of data about how products are built, and what are dependencies between design elements, requirements, functions, contractors suppliers are lost in translation with many CAD files, Excel spreadsheets, emails, and other information sources. Not only does it create a lot of inefficiencies, but also prevents companies from planning and operating more strategically and efficiently.

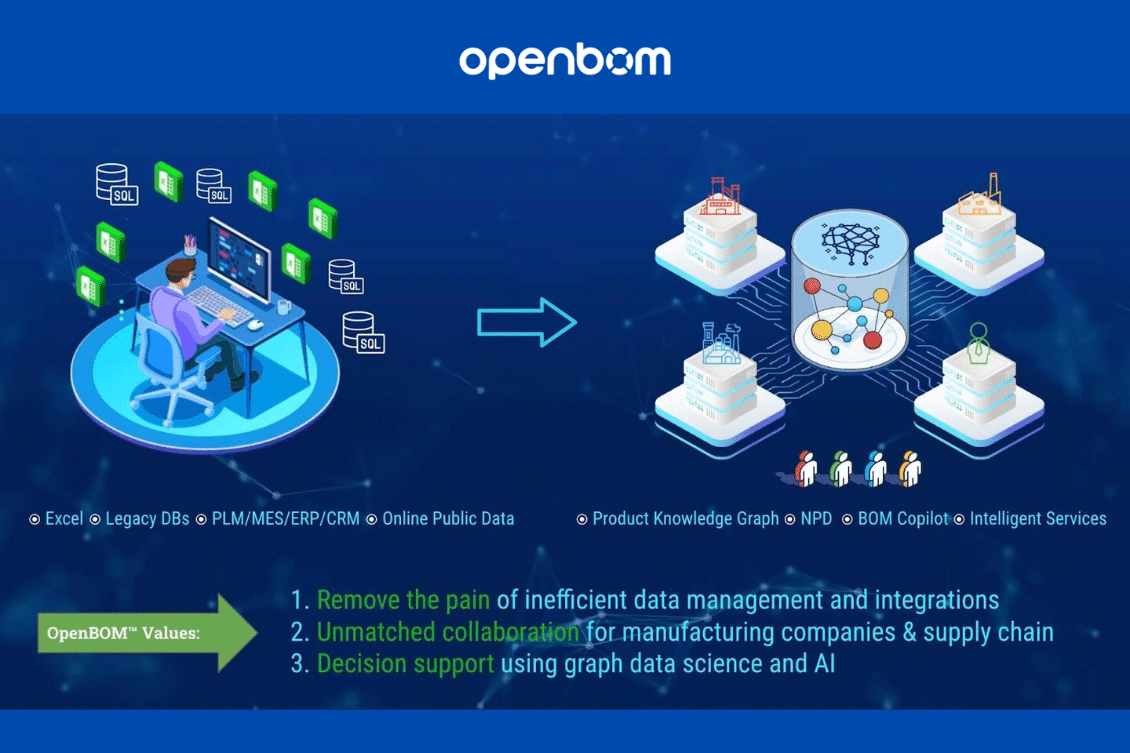

At OpenBOM, our vision is to help manufacturers transform their activities from analog (file-based) to digital processes. The core element of our activity is building a product knowledge graph, which represents a foundation of product data and will allow us to trace all relationships between product components, organizations, and processes. The product knowledge graph is not only a data management tool, but also a source of intelligence and future manufacturing and product development AI (I will talk about it separately).

Product Knowledge Graph Vision

At OpenBOM, we are inspired by a grand vision: to gather and transform the disparate and widely distributed information about products and product development process into a form that is readily accessible and become a foundation of analytics and AI tools. This will assist engineering and manufacturing companies in their product development and decision-making processes. For more information, refer to my previous article titled OpenBOM Product Knowledge Graph Vision and Roadmap/

In our blog today, I’d like to focus on demonstrating how OpenBOM can help you manage data and capture information.

Moving from multiple CAD systems to BOMs and Product Graphs

In the live demo earlier this week, we presented OpenBOM’s capabilities to manage CAD files and capture product information using a flexible product model with a seamless user experience integrated with all CAD systems.

The vision behind that is to design a digital thread helping to capture data from multiple design data sources.

To integrate the data and help the organization we provide the following strategy for information maturity – (1) capturing files, (2) agile lifecycle process and (3) connecting digital thread.

The outcome is a connected set of information about products captured from multiple sources. In our example today these are SOLIDWORKS, Altium Design, Fusion360, combined into an easy and intuitive user interface with graph navigation capabilities.

Live Demo

Check the live demo where you can see how the real process is happening. You will see how you can take multiple CAD systems (eg. SOLIDWORKS, Altium and Fusion360), to manage CAD files and combine the entire information into a reusable, manageable, and shareable set of information – product knowledge graph.

Conclusion

At OpenBOM, we are just at the beginning of the product knowledge graph and AI journey. We built a modern and unique product data management system capable of combining data from multiple systems, using flexible data models, and using data management and collaboration tools to share and explore the data to help engineers with their everyday tasks and help them to escape from the brutal reality of Excel spreadsheets and messy files.

REGISTER FOR FREE, and try OpenBOM today with one of your projects. It is just one click away from you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.