In this live demo, we dive into OpenBOM’s advanced capabilities for managing product structures and Bills of Materials (BOM) including the xBOM model. We’ll explore how OpenBOM’s unique data model facilitates the creation, navigation, and management of complex product data, making it a powerful tool for companies with multi-disciplinary needs.

Data Structure, Product Data Model, and Related BOMs

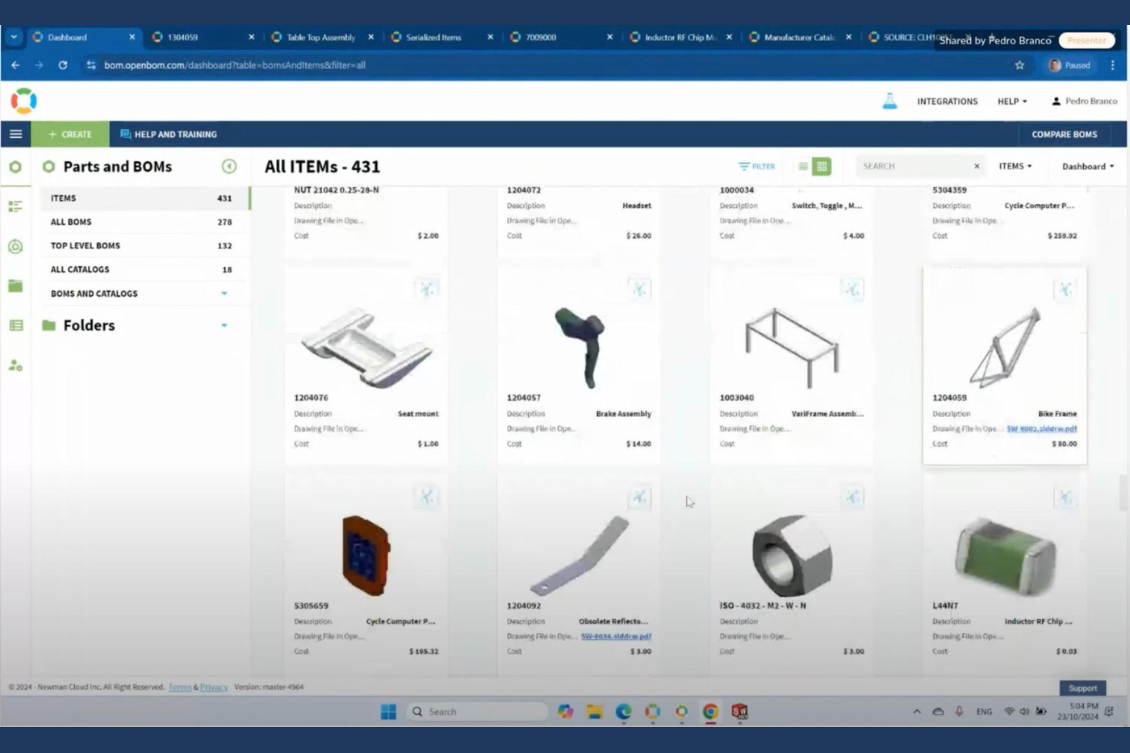

OpenBOM’s product data model stands out with its visual and intuitive interface, making it easy to navigate data elements with configurable properties, user-defined views, and structure options. Users can quickly move between linked objects and explore interconnected data, thanks to a flexible and visual layout.

This seamless navigation enhances the user experience, providing clear visibility into each element’s role in the overall product structure. Navigation using links is extremely powerful for connecting to different data sources.

The product structure can be created from multiple sources, including direct CAD integrations.

Creating Multi-Disciplinary Product Structures

OpenBOM allows you to create comprehensive product structures by integrating data directly from CAD systems and other sources. This capability is perfect for combining mechanical, electronic, software, and other elements into a cohesive multidisciplinary product structure.

The flexibility of OpenBOM’s data model means that attributes, links, objects, files, and other critical information can be easily added to product data.

Here is an example of including a PCB BOM into a mechanical BOM.

And here is an example of including software BOM elements in the same comprehensive BOM structure.

Configurable xBOM Data Model

One of OpenBOM’s defining features is its configurable xBOM data model, allowing for the creation of multiple product structures, such as Engineering BOM (EBOM), Manufacturing BOM (MBOM), and Service BOM (SBOM).

It also supports regional customization, different model versions, and maintenance configurations like Serialization BOMs. This flexibility ensures that product data can be adapted to the unique needs of different departments, countries, and lifecycle stages.

Learn more about OpenBOM xBOM here.

Vendor and Manufacturer Integration

OpenBOM enables companies to connect multiple vendors and manufacturers to their product structures, creating a complete and accurate representation of their supply chain. This feature enhances traceability and visibility, facilitating smooth collaboration with partners and suppliers.

Real-Time Collaboration and Sharing

OpenBOM’s real-time sharing feature supports collaboration across multiple organizations, with customizable access based on user roles. This allows different teams to work simultaneously on product data while maintaining a single source of truth. Additionally, export options are available for offline access and reporting.

Video Demonstration and Examples

The demo includes a hands-on example showcasing various BOMs, such as EBOM, MBOM, and SBOM. The video provides a clear overview of how OpenBOM’s flexible product data model handles these configurations, making it easy to understand the platform’s powerful capabilities.

Conclusion

OpenBOM is unique for its simplicity and configurability of data models. Combined with a simple spreadsheet-like configurable user interface it stands out to manage complex product structures and data for modern manufacturing products and connected processes. Its customization allows it to include all data properties in a very flexible way.

OpenBOM’s flexible data model and xBOM product structure capabilities provide an advanced solution for managing sophisticated product structures, supporting complex, multi-disciplinary products, and various lifecycle options.

REGISTER FOR FREE to explore OpenBOM’s capabilities and see how it can enhance your product management processes.

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.