The digital transformation goal of every manufacturing company is to integrate design, quoting, and production. These three elements (or processes) cover the main product development loop of every engineering or product development organization.

At OpenBOM, our mission is to create seamless connections between CAD design, part and assembly quoting, and production processes. The core of this vision is the Digital BOM, a powerful digital data model that links all aspects of engineering and manufacturing data—design, engineering, and production orders—into a unified, agile workflow.

This live demo webinar showcases how OpenBOM enables you to manage engineering data, track production processes, and (as an example) to integrate effortlessly with QuickBooks Online for streamlined procurement and order management.

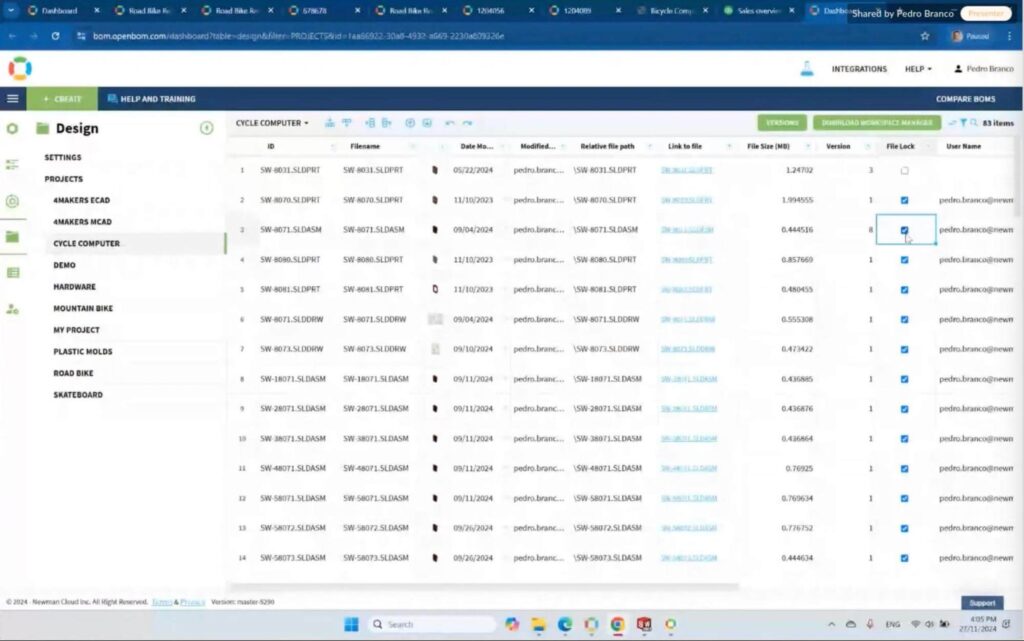

Starting with Design Projects: Seamless Connection to CAD

The journey begins with managing design projects. It is a foundation of all design data managed in the cloud and synced with local workspaces using OpenBOM Smart Sync technology.

OpenBOM ensures that your CAD files, designs, and engineering data are organized and accessible to the entire team.

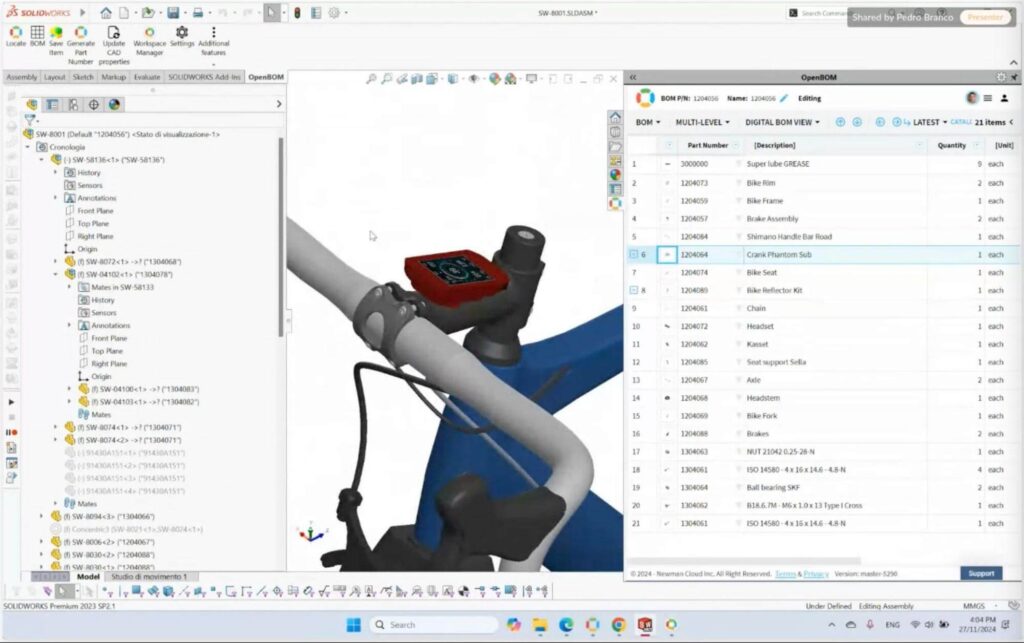

- CAD Integration: Connect your preferred CAD tool to OpenBOM to automatically capture and synchronize design information.

- File Management: Store and organize design files centrally, ensuring that everyone has access to the latest version without risking accidental overrides.

- Collaborative Locking: Implement collaborative locks on files and BOMs, enabling team members to work without conflicts.

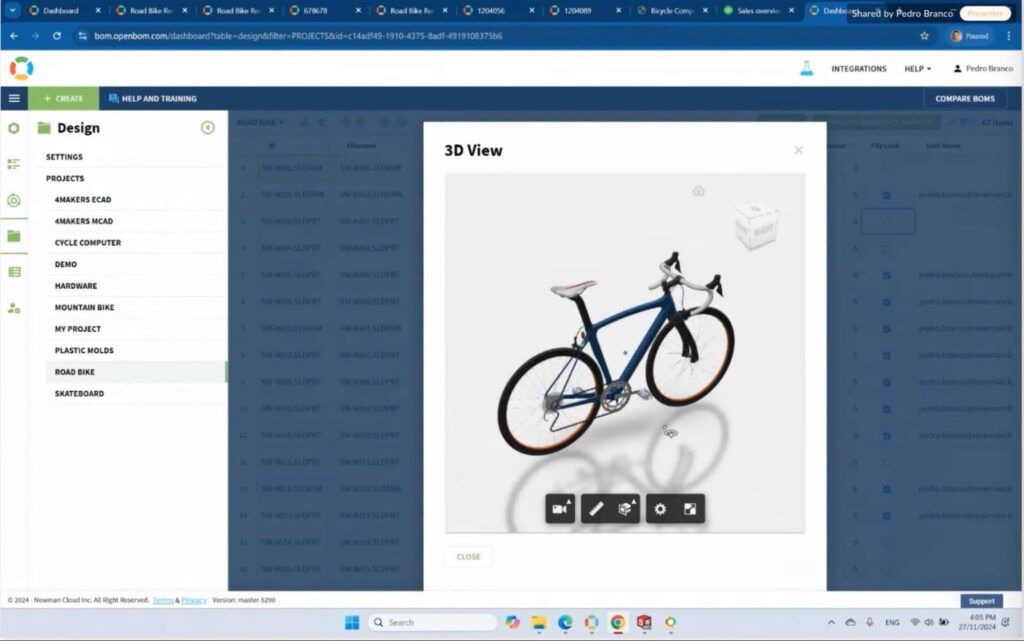

Seamless integration with CAD is a foundational part of OpenBOM strategy.OpenBOM Design Projects are also visual and you can see 3D data stored in OpenBOM cloud.

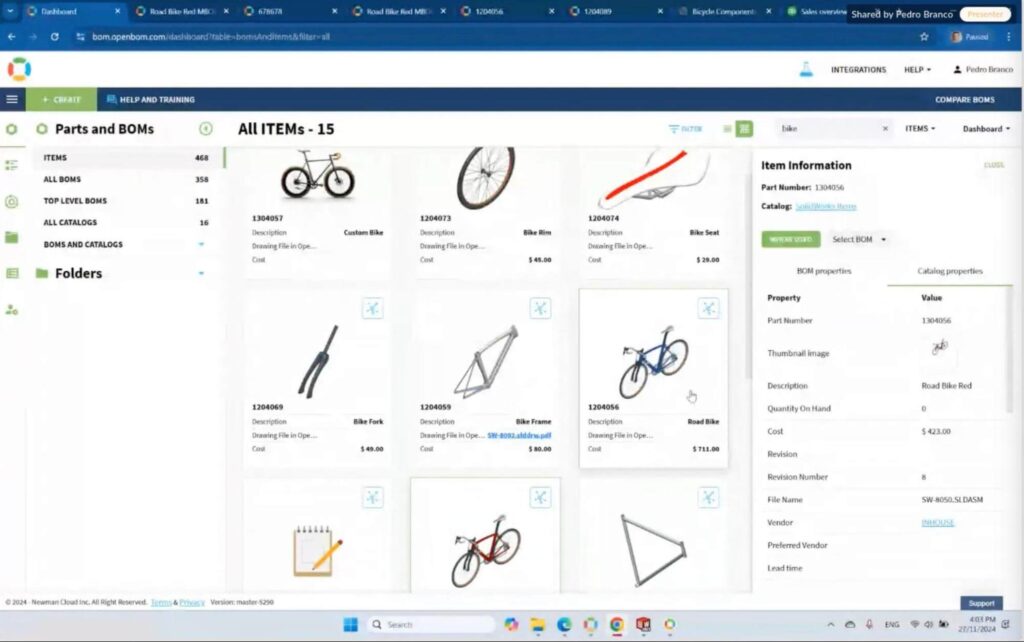

Capturing Digital BOMs and Managing Revisions

As you progress with your 3D CAD design, it is the time to capture the Bill of Materials (BOM) and start preparing for production. An important part of making it early so you will have enough time to deal with LLI (long lead items) for procurement.

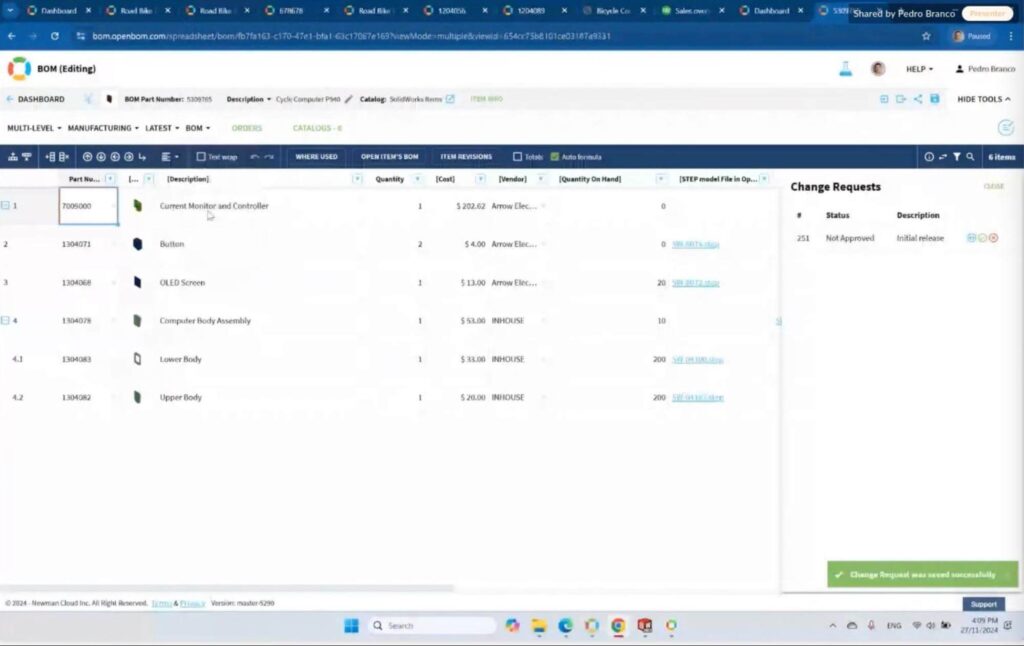

It is very important that OpenBOM allows you to do so in a seamless way and embedded in the CAD system (eg. Solidworks). It includes two phases – (1) BOM Capture: Automatically generate a comprehensive BOM directly from your design. Include critical details like parts, quantities, and suppliers.

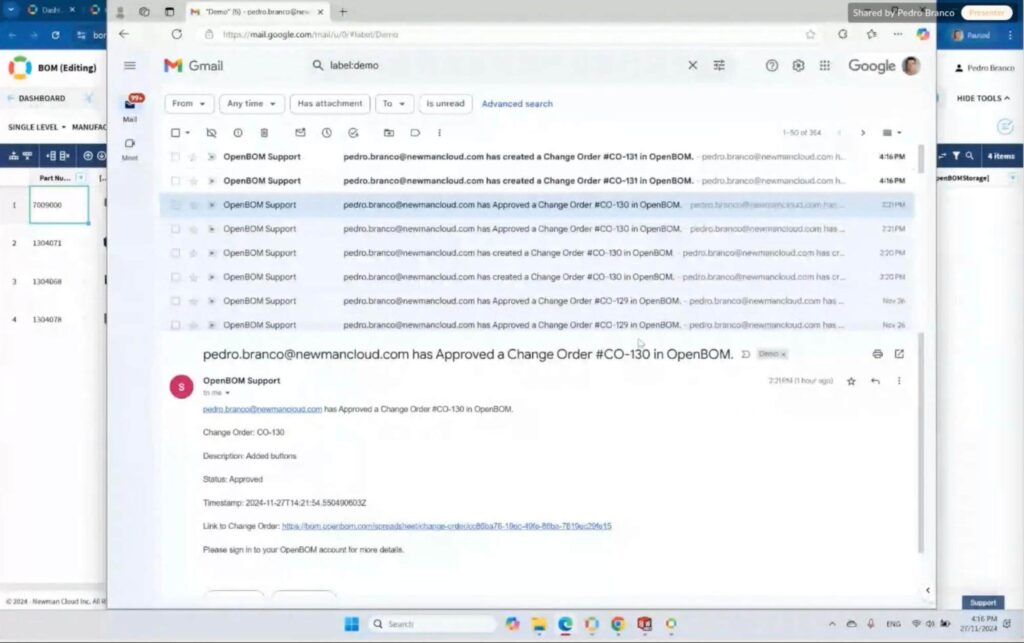

Release and Revision Management: Use OpenBOM to create revisions and route them for approval. This ensures that everyone is aligned before moving forward with production.

Users will get notifications by email about the approvals.

Moving to Production: Creating Orders and Generating POs

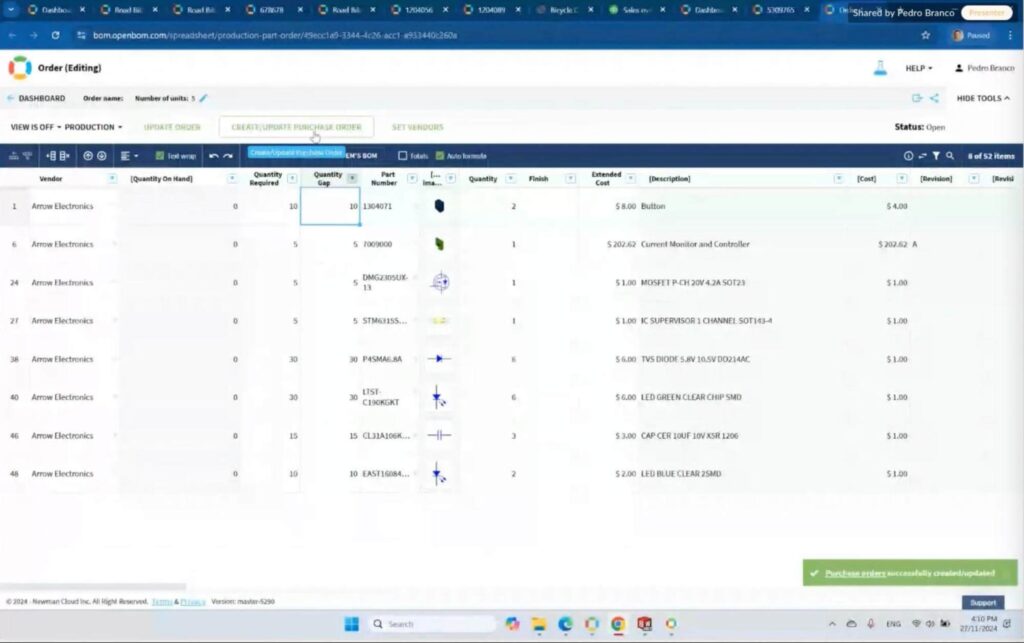

With the first BOM revision, you’re ready to transition to production. OpenBOM gives a full traceability between design, engineering BOM, manufacturing BOM (if needed) and production order including PO.

OpenBOM connects the information and quickly calculates everything you’re missing to assess what needs to be ordered and start RFQ/PO

- Production Order Management: Create your first production order and define the quantity of items needed.

- Gap Analysis: Identify gaps between inventory and production requirements, ensuring no surprises during procurement.

- Purchase Order (PO) Generation: Automatically generate purchase orders for missing items and send them directly to suppliers.

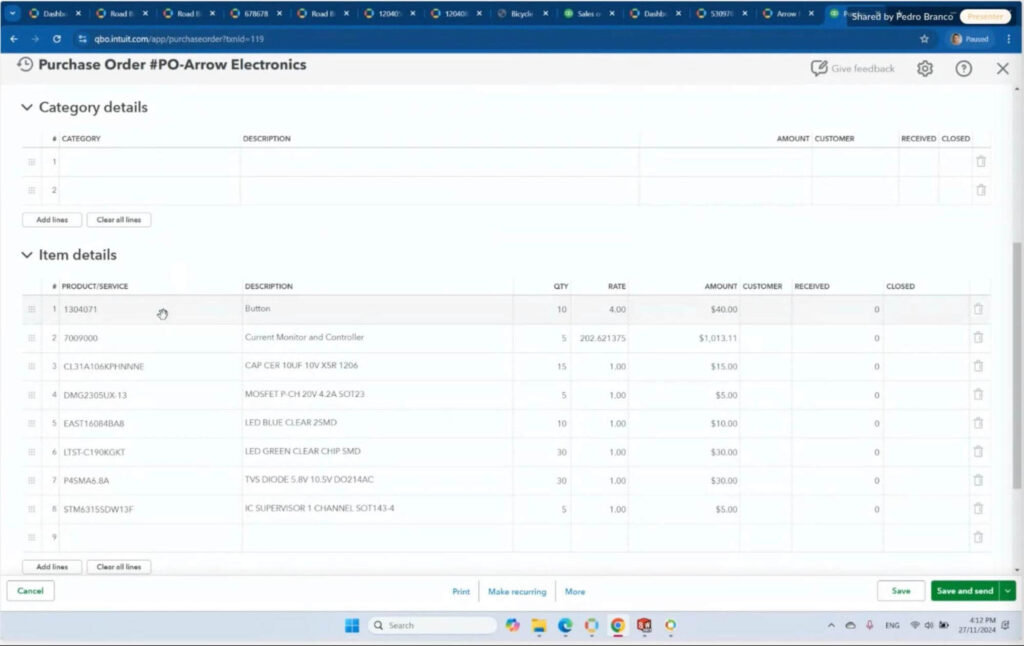

As an example in this live demo, we created a PO and shared it with Quickbooks.

If you’re not using Quickbooks, other financial and ERP tools can be used. See our Live Demo about how to connect OpenBOM to ERP – including a demo with Odoo ERP.

The Power of a Connected Process

The heart of OpenBOM’s transformational approach is its connected process. Unlike traditional workflows that rely on disconnected spreadsheets and emails, OpenBOM creates a unified environment where every update flows seamlessly across all stages:

- Data Transformation: moving from disconnected emails and files to a connected process allowing to make a change to the design, and it cascades through the BOM, production order, and procurement process.

- Process Transformation: Establishing a connected process from emails and spreadsheets. It eliminates the risk of errors and delays caused by manual data entry or miscommunication.

Check for more information here – What OpenBOM Can Do for Me: Unlocking the Power of a Connected Product Development Process.

Watch the Live Demo

Ready to see OpenBOM in action? Check out the live demo to experience firsthand how OpenBOM transforms your engineering and manufacturing workflows. From capturing design data to managing production orders and integrating with QuickBooks Online, this demo covers it all.

Conclusion: Transforming Data and Processes with OpenBOM

OpenBOM is not just about managing data – it’s about transforming processes. By shifting from disconnected documents and emails to a connected, agile environment, OpenBOM empowers engineering and manufacturing teams to collaborate effectively and make data-driven decisions.

REGISTER FOR FREE and start transforming your workflows today!

Whether you’re an engineer, procurement manager, or business owner, OpenBOM is your partner in driving innovation and efficiency across design and production. Let’s connect the dots and take your processes to the next level!

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.