Managing CAD file versions and Item revisions during product release can be a complex and confusing task for many engineers and product development organizations. Although PDM systems were around for the last 30+ years, most of the companies were focused on how to manage files and perform document management. These days, the complexity of products is growing and so are PDM and PLM best practices. Modern products are systems that include mechanical, electronic, and software elements. Therefore, companies are moving from document-oriented product data management (PDM) methods to more comprehensive product lifecycle management (PLM) best practices and demand management of multi-disciplinary BOM management as part of product lifecycle management (PLM) practices.

Revisions in CAD refer to changes made to the design of a product. CAD software allows engineers to create and modify designs quickly and easily. However, these changes can have a ripple effect on the product’s BOM. For example, a change in the size or shape of a component may require a different material, which will need to be reflected in the BOM. Managing these changes is essential to ensure that the BOM accurately reflects the product’s design.

What does it mean and how does it work in modern product lifecycle management in OpenBOM? Let’s talk about it in this article.

Best Practices for CAD Design, Items, and BOMs

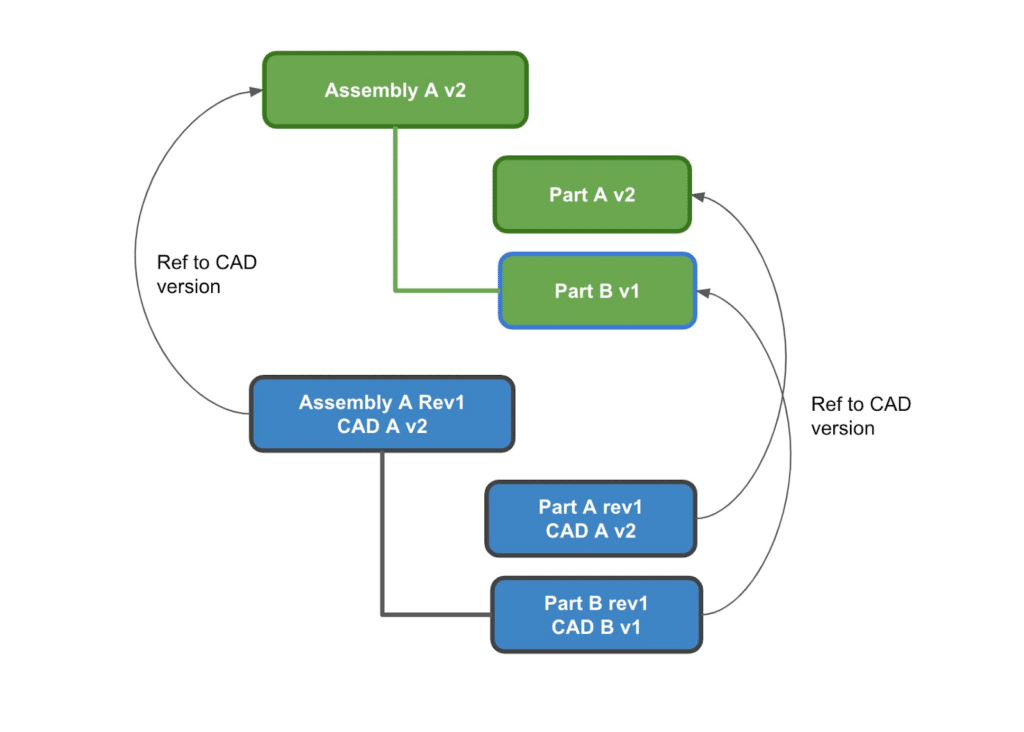

In my earlier article about Best Practices for CAD, Items, and BOMs, I discussed why is it important to track both CAD revision and Item revision simultaneously. Managing changes in both CAD design and Item/BOMs is a complex process. The complexity is increasing in modern products because of the multi-disciplinary nature of the products (mechanical, electrical, software components) as well as because of the work done in parallel by engineering and manufacturing planning teams. To maintain changes and revision traceability we recommend using CAD version/revision reference in Items. OpenBOM flexibility data model allows you to organize these reference fields. Updates coming in all CAD add-ins will provide automatic support for these data fields.

This is the picture that demonstrates the data model and relationships between CAD data and Items/BOMs.

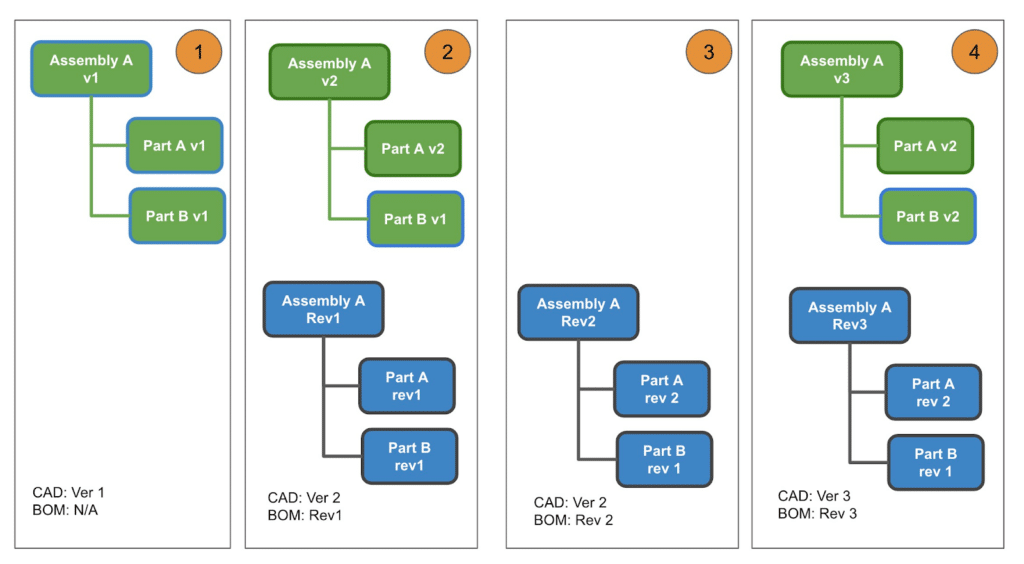

The following picture demonstrates a simplified diagram of how changes can happen in parallel in both design and engineering structures. You can see steps 1-4 and during these steps, changes are happening in parallel in design and EBOM.

Manage Revisions in CAD and BOMs

Computer-aided design (CAD) and bill of materials (BOM) management are crucial components of the modern manufacturing process. CAD is used to create 2D and 3D models of products, while BOM is used to track all the materials required to build the product. Both CAD and BOM are integral to the product design and development process. As such, managing revisions in CAD and BOMs is essential to ensure the smooth and efficient production of high-quality products.

Managing revisions in CAD and BOMs is a multi-step process that involves several stakeholders, including designers, engineers, and production teams. In the following video, we demonstrate how to manage Revision in both CAD (Solidworks) and Items (OpenBOM) using OpenBOM Add-in for Solidworks.

CAD Revision support in SOLIDWORKS add-in

This is a big deal. We have been listening to the CAD folks about managing Revisions in OpenBOM, and about the need to track Revisions in CAD data separately from Revisions in OpenBOM. Up till now, CAD and OpenBOM both shared the same Revision property.

With this release, we deliver the ability to send your CAD Revision to an OpenBOM CAD Revision property!

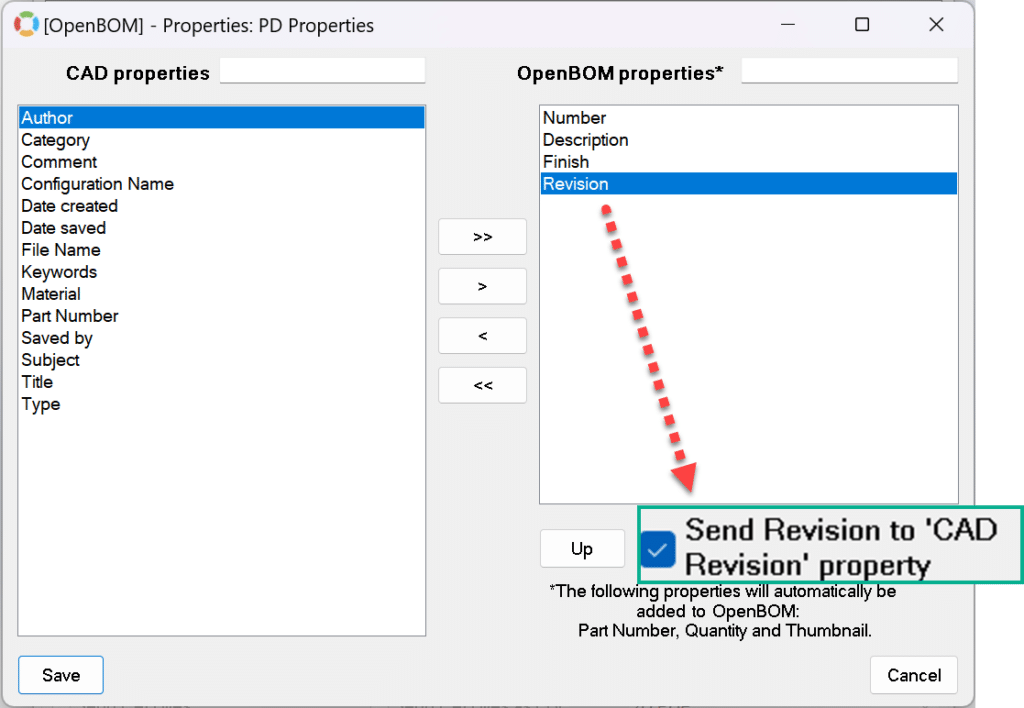

Here is how it works. When you select Revision in your CAD properties, OpenBOM will give you the option to send it to a separate OpenBOM property called CAD Revision, thereby keeping CAD and OpenBOM Revision logic and values separate.

You have the power of the OpenBOM Revision command while keeping the CAD Revision value for reference.

To start, select Revision from the CAD property selection list then look for the option to “Send Revision to CAD Revision property”. When enabled, a new CAD Revision property will appear in OpenBOM and it will have the value of Revsion from CAD.

You can view a demonstration of the feature of how to create both CAD revision and Item revision in the catalog and map it from CAD file by watching the video below.

Conclusion:

Managing revisions in CAD and BOMs is a critical aspect of the product development process. It requires a formal revision control system, the establishment of traceability protocols (data fields) for both CAD and Item Revision, and clear communication to support them. OpenBOM for SOLIDWORKS Add-in supports CAD Revision logic. Similar logic will be implemented in all other OpenBOM CAD Add-ins soon. By implementing these best practices, manufacturers can ensure that their products are of the highest quality and meet all customer requirements.

REGISTER FOR FREE to start a 14-day trial and explore how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.