In the ever-evolving realm of mechanical design, few names resonate as powerfully as SOLIDWORKS. Over the years, this software has transformed from a mere tool into a beacon of innovation, setting the pace and direction for the industry at large. Its blend of user-friendly interfaces, robust features, and an ever-growing community has positioned SOLIDWORKS not just as another CAD software but as the de-facto standard in mechanical design. From small-scale inventors to global manufacturing giants, its adoption spans the breadth and depth of the industry, a testament to its unmatched capabilities and influence. When one thinks of mechanical design in the modern age, it’s hard not to have SOLIDWORKS come to mind – a true testament to its reigning popularity.

Digital Transformation and Data Management

The Age of Digital Transformation In today’s swiftly evolving digital landscape, effective data management is more crucial than ever before. Especially in the field of design and manufacturing, where the creation of tangible products relies heavily on intangible data. As software like SOLIDWORKS continues to redefine the boundaries of what designers and engineers can accomplish, it also brings forth an increasing need for reliable data management solutions. The true essence of digital transformation lies not just in implementing advanced tools but in effectively managing the plethora of data these tools generate.

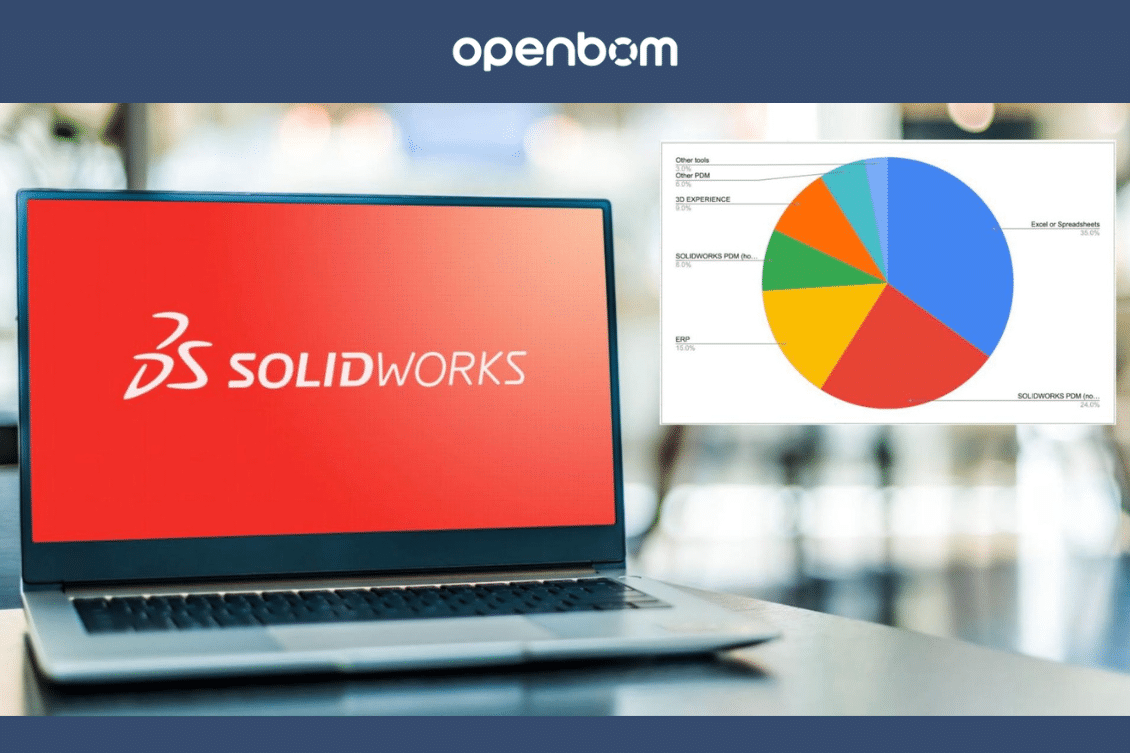

But how do SOLIDWORKS users currently manage their data? I conducted a LinkedIn poll in a large SOLIDWORKS user group, which shed light on some fascinating trends. The results are based on ~1500 votes.

The Survey’s Revealing Insights

Out of the many tools available for data management, here are the top three as per the poll:

- Excel (or other spreadsheets) – 35%: It’s somewhat surprising, but the trusty Excel spreadsheet remains the leading method for managing SOLIDWORKS data. This suggests that many users still prefer the familiarity and simplicity of spreadsheets. While Excel is versatile and accessible, it may not be the most efficient method for handling complex data structures inherent in CAD and product design.

- On-premise SOLIDWORKS PDM (Product Data Management) – 23%: PDM systems are designed specifically for managing and tracking the vast amounts of data generated during product development. That nearly a quarter of respondents use on-premise PDM systems speaks to the recognition of the need for specialized solutions.

- ERP (Enterprise Resource Planning) Systems – 15%: ERP systems, typically employed to integrate various business processes and facilitate the flow of information within an organization, are also used by a significant fraction of SOLIDWORKS users for data management. While they might not be as specialized as PDMs, they offer holistic solutions that cater to a broader range of organizational needs.

OpenBOM and SOLIDWORKS Users

Of particular note is that more than 50% of OpenBOM customers are SOLIDWORKS users. OpenBOM, a modern inventory and order management system, offers simplicity, ease of use, and seamless integration. This high adoption rate among SOLIDWORKS users indicates a growing trend towards seeking out specialized, yet simple, tools that can work in tandem with the main CAD software.

Here is one story from BloomX (Bumblebee AI) about their selection process and experience with OpenBOM.

“We looked at Teamcenter and Solidworks EPDM. While both met some of our functional needs, they were just too much cost for us to implement. We needed something quick and scaled to our financial needs – these were just too much money to buy and implement and took way too long.”

“OpenBOM has outstanding Solidworks integration and lets us take our designs from GrabCAD straight into OpenBOM.”

“We started small with OpenBOM features, and gradually grew into it. The onboarding and support from the OpenBOM team are excellent.”

“The cost analysis we can do now with a reliable BOM is very important to the company and the where-used feature lets us analyze the impact of a single change across the product line. We didn’t know what we were missing, neither of these features is available in CAD BOM tools.”

Another story is from Nexa3D – Nexa3D Accelerates Product Development and Integrates BOM Management Process with Solidworks and Altium CAD using OpenBOM. Nexa3D needed a way to keep separate product BOMs reliable as they moved from design to manufacture.

“Our company needed the traceability and history we could not get with a traditional spreadsheet”, he says. “It was simply impossible, even with a small team, to keep data reliable and intact as we shared with procurement.”

The reliance on Excel also did not meet the company’s need to manage sub-assemblies.

“Even with a very capable team, and an extraordinary amount of effort, and many vlookup macros, Excel could not deliver what we needed, it was fragile and the logic would simply break”, Kenyon says.

“As the Nexa3D products matured we soon had a BOM administrator dedicating 20 hours a week to maintaining Excel BOMs. With OpenBOM we have no single admin. OpenBOM is largely self-sufficient, no dedicated IT person is needed. It just works.”

“Looking back to the decision to buy OpenBOM over two years ago it was rather simple. We needed a solution with low capital investment. SAP and Oracle were out as they require full-time admin. We were lean and agile and wanted a BOM solution that would grow with us and suited to our company. No overhead of a complicated system”, he explains.

“We looked at Arena PLM, it was a bit more than we needed and required more administration than OpenBOM, the onboarding time and cost was higher than we could justify.”

“OpenBOM was more mature and built a better BOM. So we decided to buy OpenBOM.”

Learn more about how customers use OpenBOM. Check customer stories on our website and G2 reviews online.

Conclusion:

Seamless integration and simplicity are two important trends in engineering systems. They are demonstrating a shift in user preferences. While traditional tools like Excel remain popular, there’s a clear trend toward adopting more specialized solutions that offer seamless integration and simplicity. The rise in OpenBOM’s popularity among SOLIDWORKS users underscores this. As the world of design and manufacturing continues to undergo digital transformation, the tools that offer both power and simplicity will undoubtedly lead the way.

REGISTER FOR FREE and check how OpenBOM can help you to manage SOLIDWORKS data.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.