Robots are everywhere in our lives these days. While they might not look exactly like humans, the manufacturing of products with robotics behavior is skyrocketing. The RPA market is booming and expected to reach nearly $3 billion this year as new vendors compete with larger established RPA specialists and tech giants for enterprise automation business. The benefits can be seen in multiple ways – manufacturers are getting purpose-built robotic equipment to automate some tasks, consumers are relying on some of the automation that can make their life easier and lower the cost of operation.

Complexity Challenges

It is easy to see the benefits of automation and robotics equipment. But building robots require the next level of skills in product development, production planning, and procurement. The complexity of multi-disciplinary BOMs and product lifecycle, needs to track mechanical, electronics, and software components, supply chain challenges and the need to manage efficient contract manufacturing operations is only a shortlist of the challenges for robotics companies.

At OpenBOM we are proudly supporting many robotics manufacturers by providing them with a reliable and robust platform that manages product information lifecycle, estimates cost, plans procurement, and connects with contractors and suppliers around the world.

In my article today, I would like to bring four examples of manufacturers building robotic equipment or products. They look different, but each of these products and manufacturers share a common need to manage a complex product development process, which includes complex data, relationships and operations. So, here are these companies.

FF Robotics

As you can imagine, the machine that mimics the gentleness of a human requires sophistication and precision so FF Robotics selected OpenBOM to speed that innovation to market.

“With over 16K individual parts, we needed a better way to manage components,” says FFRobotics co-founder Yoav Koster.

“We needed to reduce the number of specific part numbers and OpenBOM makes it easy to understand where each and everyone of the components is being used,” says Yoav.

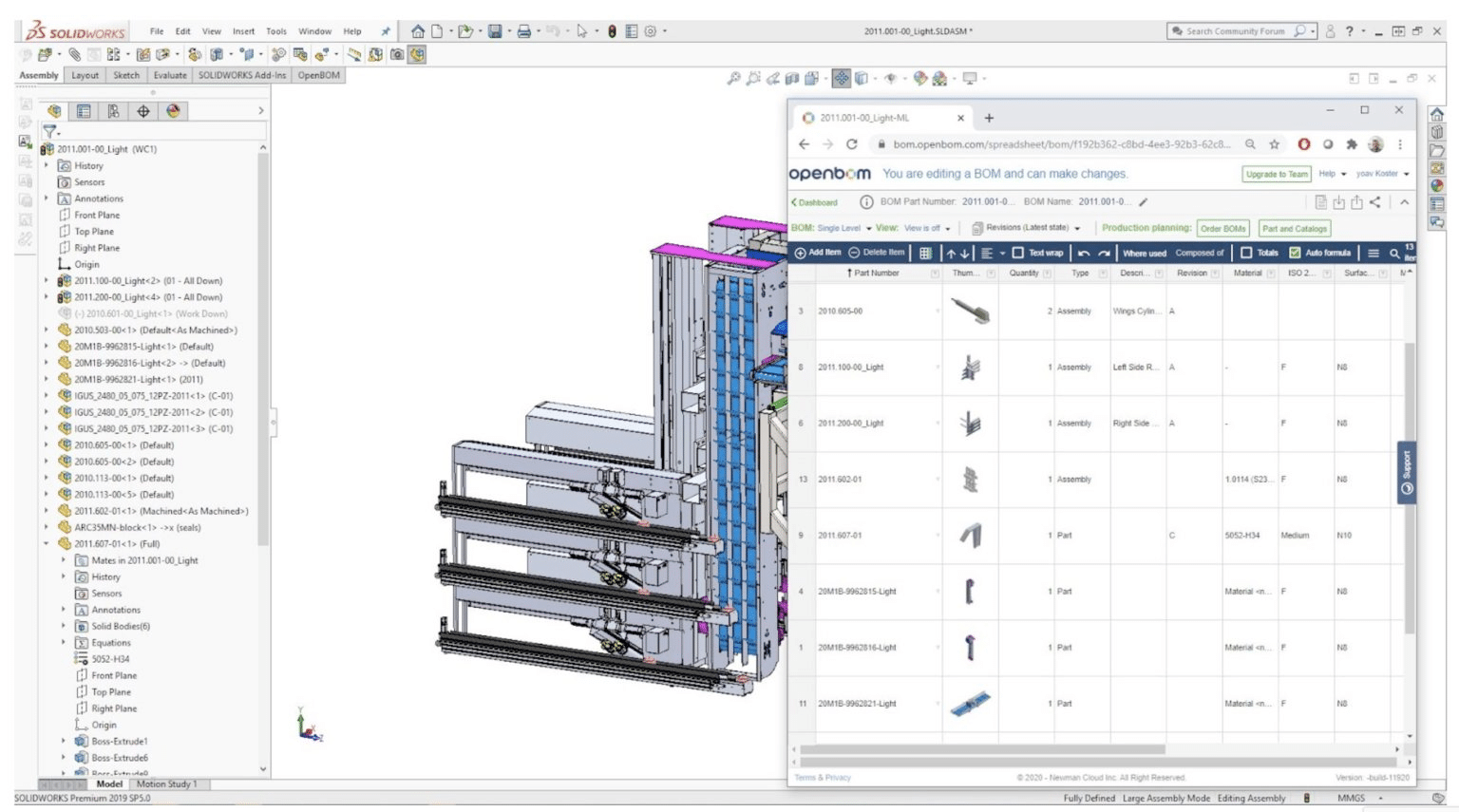

Something which was not the case when he was using Excel. “Getting our BOMs out of Solidworks in Excel was hard. We would add some non-modeled items like hardware then have to manage all those additions individually each time we updated the Excel from Solidworks”.

Using OpenBOM with SolidWorks and PDMWorks is much much easier, he says.

“OpenBOM easily manages and tracks our part numbers” he goes on to say, “something as simple as finding where a part is used is easy with OpenBOM’s where-used command; not having to open our CAD and look for a part is a huge time-saving.”

Fly Pyka

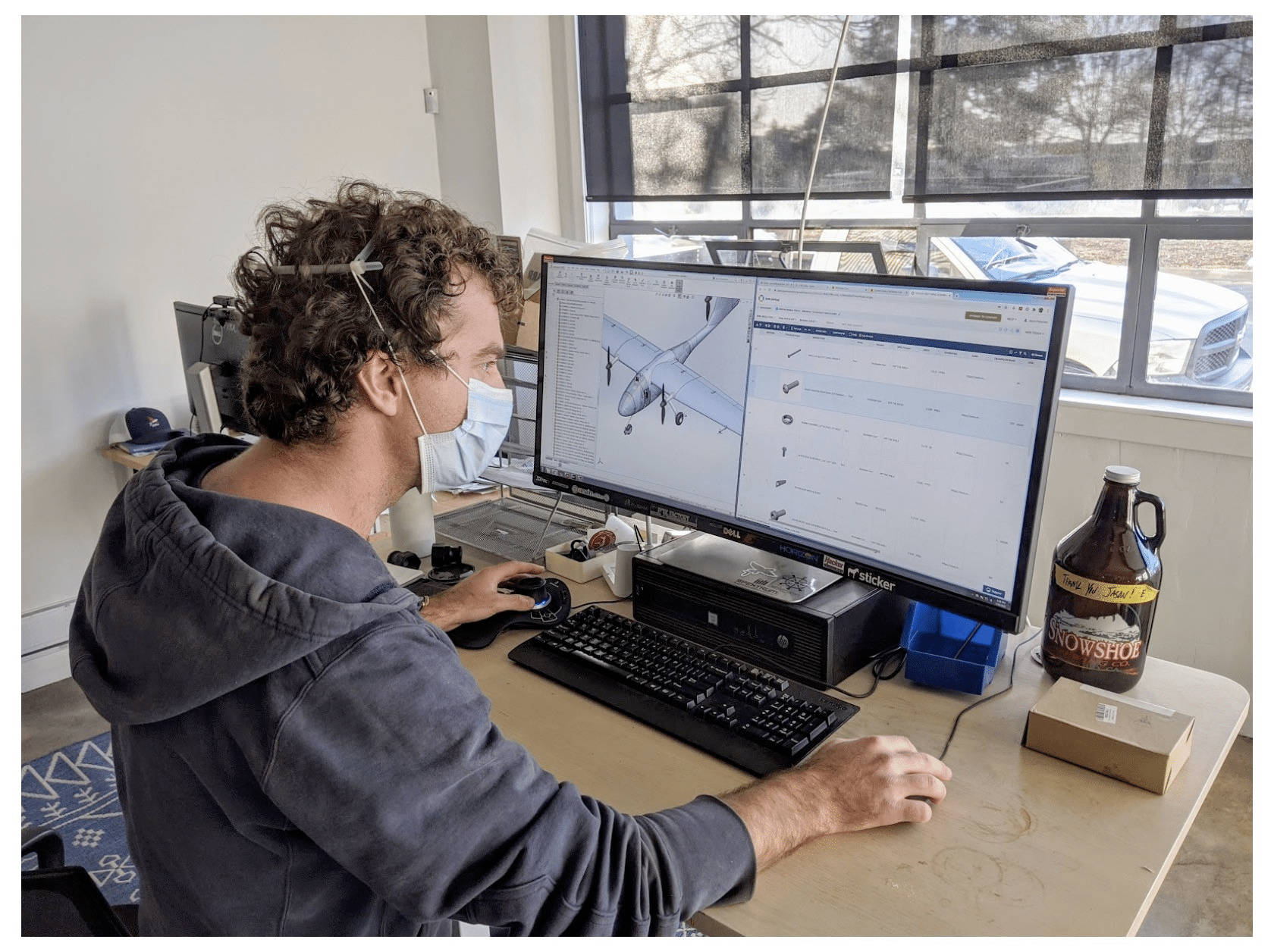

The Pyka team also often has to answer that classic question, “Which motor controller is in what plane?” Well, the OpenBOM Where-Used feature helps them do just that.

They also like the way non-modeled parts can easily be added to the BOM in OpenBOM, no longer requiring the CAD engineer to account for every screw or fastener.

“When we share the BOM with the manufacturing team, they simply click the link, get the proper step file or control specification. No copies of documents or files, no more emailing or validating if we have the proper STEP file”.

Finally, Garrett says “OpenBOM is the Pyka source of truth! It’s a huge benefit for everyone involved. We put everything in there and we can pull back out just the views and information that is relevant to each party involved. We simply couldn’t do that with a spreadsheet”.

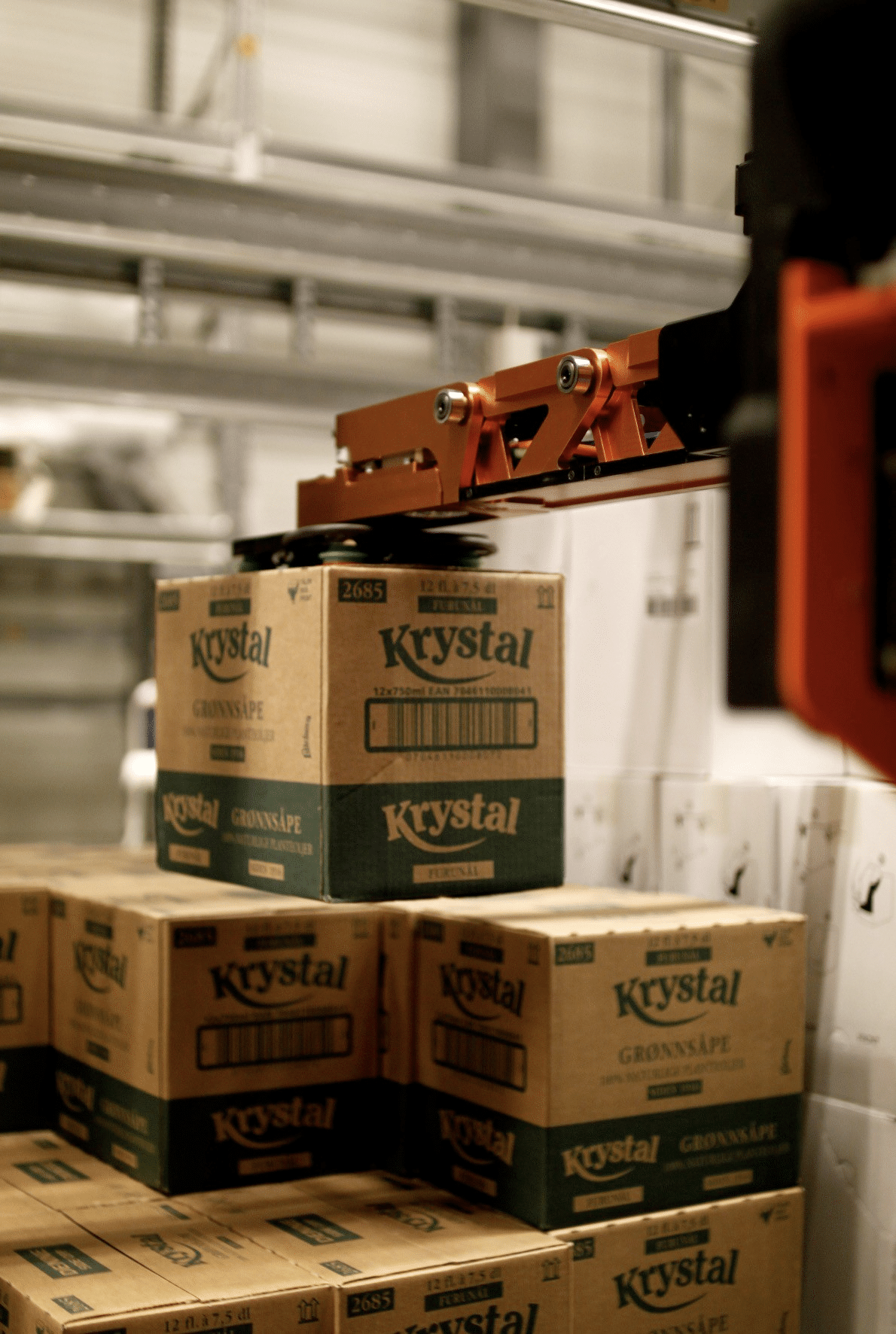

Currence Robotics

“There are many shapes and sizes of grocery products”, he says, “it is hard to compete with the versatility of the human hand,” says Eivind. The Currence Robotics design team relies on OpenBOM to help work through the evolution of their designs.

“Initially we settled on OpenBOM as a logical extension to our 3D design platform, Onshape. We saw the opportunity to leverage all metadata in Onshape but needed an organized way to bring it to the company (many of which were not engineers) for production. With OpenBOM we get the very reliable Onshape integration AND the ability to add and extend the data set as it flows through our company”

“The OpenBOM Catalog is the best way to keep track of metadata from Onshape. We keep design info in CAD and the business data in OpenBOM. That way our Onshape design is relatively constant and unchanging as the design matures, then as we go to manufacturing OpenBOM gets the changing/business data like Cost, lead time, vendor, etc., all without disrupting the CAD and engineering teams”.

According to Eivind, Currence Robotics likes OpenBOM as a solution because it is “Accessible, not very expensive, easy to implement and deploy to our staff and comes without the overhead of Big PLM.”

Build With Robots

The company’s Director of Product Engineering, Ryan Martin, is responsible for the overall product delivery and quality and is tasked with scaling capacity as the business quickly grows. OpenBOM is the system of record that defines our product. Non-modeled items are added in OpenBOM, Circuit Boards from Fusion 360 are integrated easily with Mechanical BOMs to create a single multi-discipline top-level BOM.

Ryan continues, “OpenBOM adds flexibility to the purchasing process. We use multiple vendors for PCB and hardware, track which vendor has been approved, which contract manufacturers and hardware suppliers are selected for a particular process, like sheet metal for example.”

“As Build With Robots goes into HVM we will be looking more to contract manufacturers to support us. We will rely more on OpenBOM as we integrate CMs into our team.”

Ryan and Build With Robots are laser-focused on quality. Most important is the value our customers receive. Our decision to buy OpenBOM means we have better insight into what we are building and as we scale we will bring increased quality to our customers.”

Conclusion

Building Robots is a complex process which includes the need to manage a comprehensive multi-disciplinary product structure, ability to capture information from multiple sources, manage the overall lifecycle and connect people in many organizations. These characteristics are presented in OpenBOM, which makes it a great solution for the RPA market.

Register for your FREE 14 day trial of OpenBOM and get an inside look at all the perks we have to offer.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.