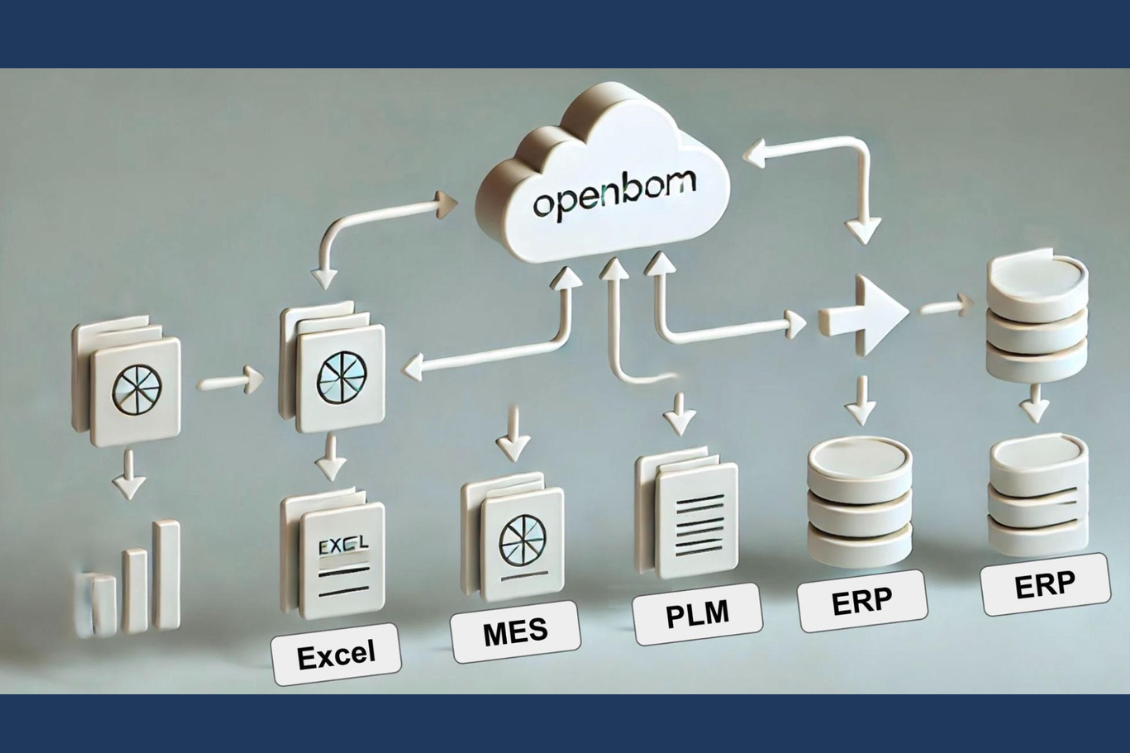

The ability to bring in legacy data from various sources, including PDM, PLM, ERP systems, and even Excel spreadsheets, is critical for organizations transitioning to modern data management platforms.

OpenBOM provides a flexible, real-time data modeling system that allows seamless import of this data through a wide range of out-of-the-box tools. And the best part? It’s all done online, making it easy to collaborate across teams. In this article, we’ll cover four best practices for importing your legacy data into OpenBOM.

Import Vendors

Vendors form the backbone of your purchasing and supply chain operations. Before diving into product and item data, it’s essential to have an accurate and comprehensive list of all the vendors you buy from.

- Organize Your Vendor Data: Start by consolidating vendor details from all legacy systems into a structured format, such as a spreadsheet or CSV file.

- Map the Data: Use OpenBOM’s import tool to map each data field, ensuring that vendor names, contact information, and relevant identifiers align properly with OpenBOM’s structure.

- Merge and Deduplicate: If you’re importing from multiple sources, OpenBOM allows you to stitch the data together, intelligently merging duplicates and combining information to create a clean and unified vendor list.

Import Catalogs and Items

Catalogs in OpenBOM represent your items’ master data. This includes all product details, specifications, and part numbers that make up your products and assemblies.

- Prepare Data from Multiple Sources: You may have item data spread across various databases or spreadsheets. OpenBOM’s powerful import functionality lets you bring in data from multiple sources, ensuring consistency.

- Stitching and Fusing Data: When importing, OpenBOM helps you stitch together different data points, automatically recognizing common fields to avoid redundancy.

- Maintain Data Accuracy: Use OpenBOM’s catalog management to keep all imported data up to date in real-time, ensuring that your master data remains accurate and reliable.

Import Bills of Materials (BOMs)

One of the most critical aspects of data migration is transferring your bills of materials. OpenBOM supports multiple methods for importing BOMs, including single- and multi-level structures.

- Single and Multi-level BOM Imports: OpenBOM allows you to import BOMs in single-level or multilevel structures, depending on your product complexity.

- Automated BOM Mapping: When importing, OpenBOM can automatically detect relationships between components and sub-assemblies, making the transition smooth and efficient.

- BOM Customization: After importing, you can further customize BOMs to match your company’s specific requirements, ensuring that all structures are accurate and complete.

Import Design Projects with SmartSync

OpenBOM’s SmartSync tool allows for seamless integration of design project data from local sources or cloud-based platforms like Google Drive.

- Sync Design Projects: Import design projects directly from local files or cloud storage, keeping all engineering and design data synchronized in real time.

- Eliminate Manual Updates: SmartSync automates the synchronization process, ensuring that every update to a design project is reflected in OpenBOM, reducing manual work and improving efficiency.

- Collaboration-Friendly: With SmartSync, multiple users can access and update the design data, fostering collaboration across teams and reducing the risk of versioning issues.

Watch Our Video Guide

For a step-by-step walkthrough of how to import legacy data into OpenBOM, check out our video guide. It will take you through the entire process with practical examples, ensuring you get the most out of OpenBOM’s import capabilities.

Conclusion

OpenBOM’s flexible data modeling system is a game changer when it comes to migrating legacy data from PDM, PLM, ERP, and Excel. Its user-friendly, real-time environment allows organizations to quickly import data and start working with accurate, up-to-date information. Whether you’re importing vendor lists, catalogs, BOMs, or entire design projects, OpenBOM provides the tools to make the process easy and efficient. With these best practices, you’ll be up and running in no time.

REGISTER FOR FREE and try OpenBOM for 14 days. Contact us, we will help you import your legacy data.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.