Bill of Materials (BOM) is an essential component in product manufacturing and design. It provides a comprehensive list of components and raw materials that are required to build a particular product. As the complexity of products and their manufacturing processes increases, the BOMs also become more intricate and multi-level. OpenBOM is a cloud-based BOM management software that provides a platform for companies to create, manage, and share BOMs with their suppliers, manufacturers, and customers.

Challenges of Data and BOM Export

Exporting data is a very important function of every business software. As much as we believe that data will live peacefully inside the business systems, the need for engineering and product development organizations is too broad and Excel (or other spreadsheet software) is still taking a big role in the day-to-day processes.

Exporting multi-level BOMs from many engineering software packages is always a challenging task. Especially when there are several components and sub-assemblies involved – multi-level BOM. To make this process more manageable, OpenBOM allows users to apply specific rules while exporting and sorting BOMs.

OpenBOM Export Options

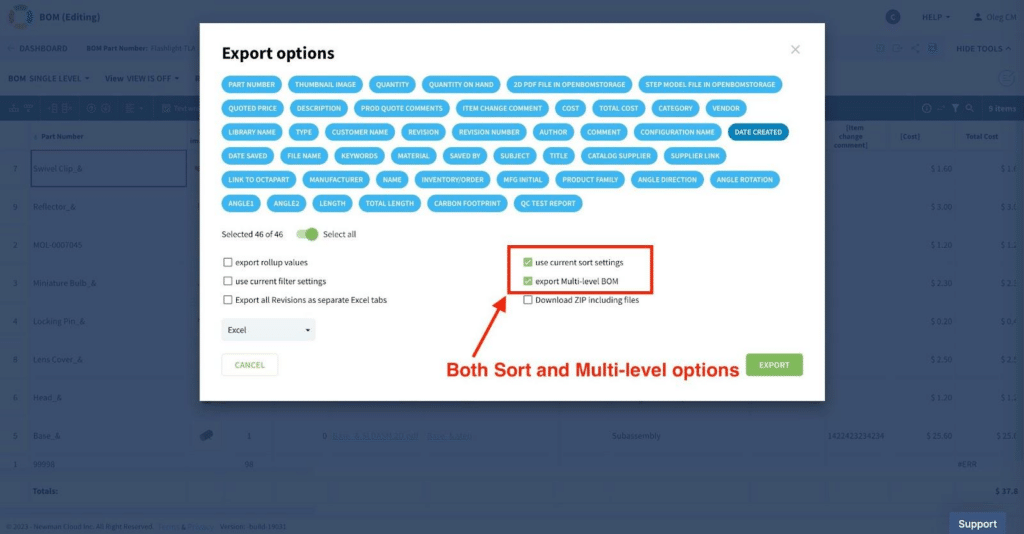

One of the key features of OpenBOM is the ability to export BOMs in various formats, such as Excel, CSV, and PDF. To export a multi-level BOM from OpenBOM, users can select the BOM they want to export and choose the export format. OpenBOM provides several export options, such as exporting all levels, exporting only the top level, or exporting a specific level. Users can also choose to export only specific columns, such as item number, description, quantity, and unit of measure.

Applying specific rules while exporting BOMs can help streamline the process and make it more efficient. For example, users can choose to export and sort together all the sub-assemblies and their components to ensure that the BOM is organized and easy to understand. OpenBOM also provides an option to export the BOM in a hierarchical format, which displays the BOM in a tree-like structure, with each level of the BOM indented to show its relationship with the other levels.

Another useful feature of OpenBOM is the ability to customize BOM exports. Users can create custom templates that define the format and content of the exported BOM. For example, users can create a template that includes specific columns, such as material type, supplier, and cost. This allows users to tailor the BOM export to their specific needs and requirements.

OpenBOM Export Sorted Multi-Level

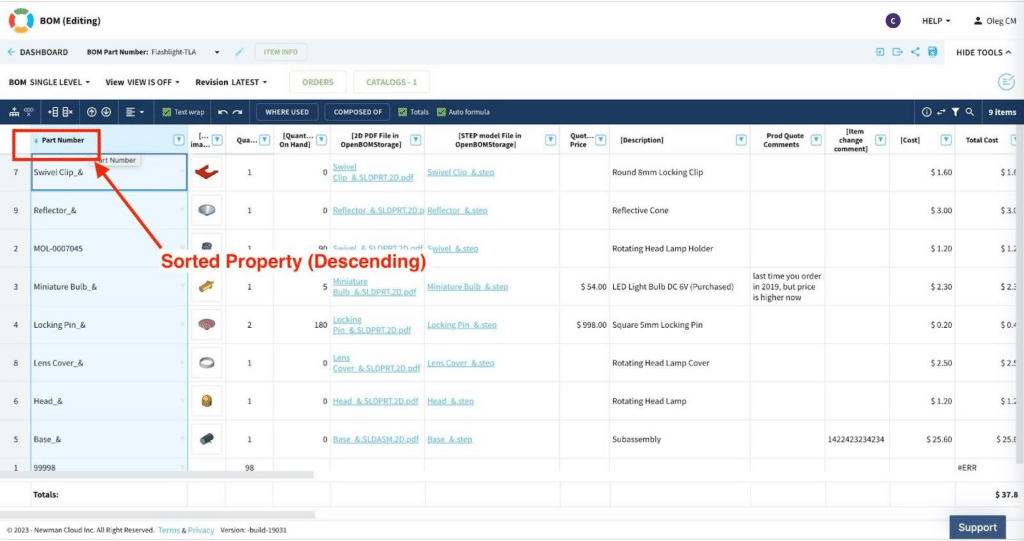

You can easily export BOM from OpenBOM by applying to sort when following these simple rules. First of all, switch the BOM to a single-level BOM option.

Once it is done, use the Export command and select the following 2 options – export sorted and multi-level.

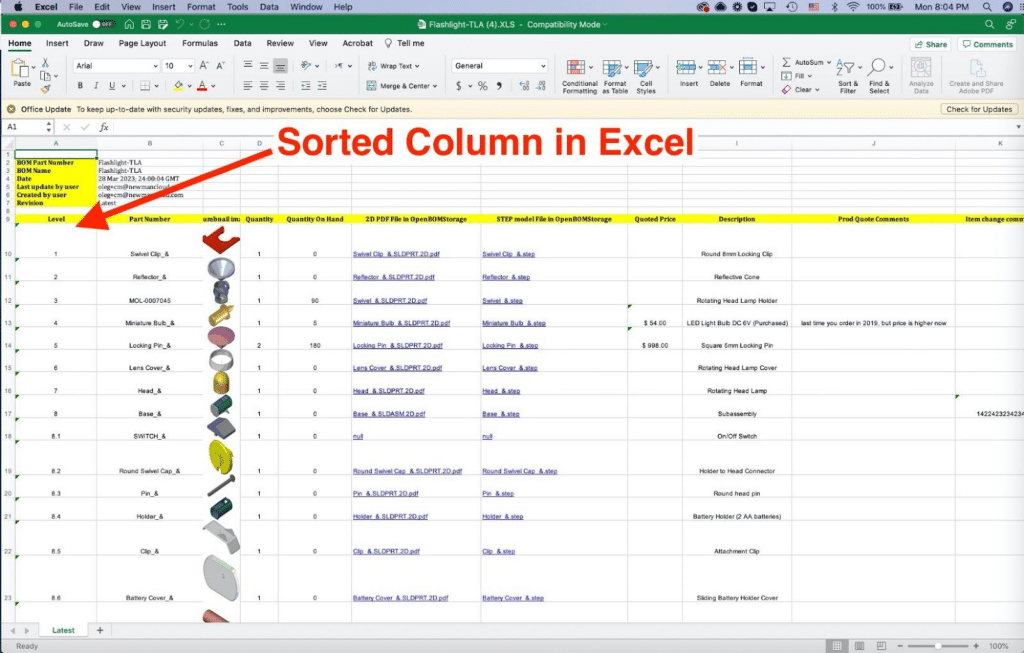

Click “Export” and your BOM will be fully exported to Excel with the preserving sort option.

Video Demo

Watch the following video to learn more about the process.

Conclusion:

Exporting multi-level BOMs from OpenBOM can be made easier by applying specific rules and using the platform’s features to customize the export. By exporting and sorting together all sub-assemblies and components, users can create an organized and easily understandable BOM. Additionally, customizing the BOM export with specific columns and formats can help streamline the manufacturing and supply chain processes. OpenBOM provides a powerful platform for managing BOMs, and by leveraging its features, companies can increase efficiency and productivity in their product development and manufacturing processes.

REGISTER FOR FREE to start your 14-day trial and learn how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.