Welcome to the final installment in our series on best practices for utilizing OpenBOM’s new xBOM feature. In previous articles, we’ve explored various aspects of xBOM, and today, we’ll cover the last piece – how revision management and change control are integrated into this innovative model. If you’ve missed any of the earlier posts, be sure to check them out for a comprehensive understanding of xBOM.

- Introducing the OpenBOM xBOM service

- xBOM service: BOM management use cases

- OpenBOM xBOM architecture for the distributed digital thread

- OpenBOM architecture for xBOM and Role-based access control

- xBOM Video Demo: Create BOM Types and Managing EBOM, MBOM and SBOM

- Management of Service and Maintenance BOM with Serial Numbers

The Importance of Revisions and Change Management in OpenBOM

Revision management and change control are critical functions within OpenBOM, designed to support Engineering Change Orders (ECO) and other change processes. These functions ensure that every modification to an item or BOM is meticulously tracked, providing a clear history and maintaining data integrity. For detailed information on how OpenBOM handles revisions and change management, refer to our documentation.

But how does this integrate with the new xBOM model?

Understanding the Core of OpenBOM Revision Management

At the heart of OpenBOM’s revision management system is the “item.” An item can represent any object type, such as a part, material, or assembly. A BOM (Bill of Materials) is a characteristic object connected to an item, outlining its components and structure.

The revision control process in OpenBOM begins with the item. When you revise an item, OpenBOM examines the associated BOMs and creates revisions for them as well. This ensures that every change is systematically recorded, maintaining a comprehensive and accurate version history. Check more about revision and change management in OpenBOM documentation.

How xBOM Enhances Revision Control

The xBOM model follows the same robust revision control process. When you create an item revision in xBOM, the system automatically generates revisions for all existing BOM types connected to that item. This integration allows for the simultaneous management of multiple BOM types, reflecting the product’s entire lifecycle and various configurations.

By maintaining this consistency across item revisions and BOM revisions, xBOM ensures that every change is accurately tracked and managed, providing a holistic view of the product’s evolution.

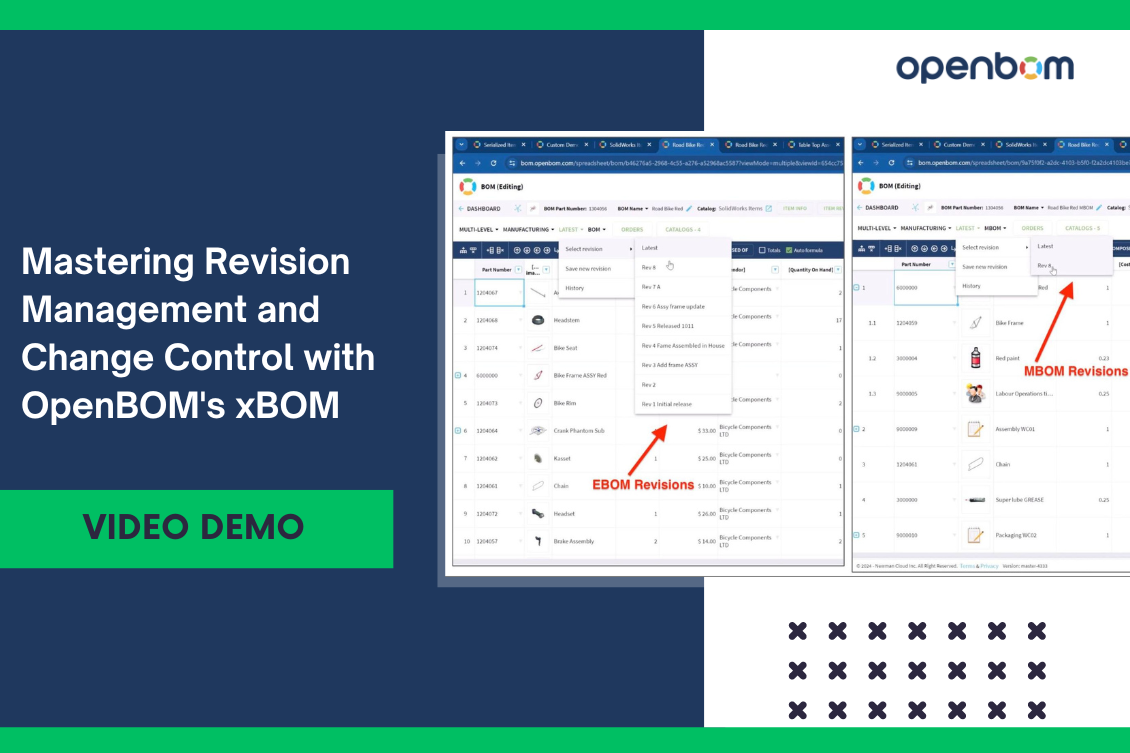

Watch the Video Demo

To see the revision mechanism in action with xBOM, check out our video demonstration. It provides a step-by-step walkthrough of how the revision control process works, highlighting the seamless integration and functionality of xBOM.

Conclusion

xBOM represents a significant advancement in OpenBOM model, enabling the creation of multiple BOM types and providing a comprehensive representation of the product throughout its lifecycle – engineering, manufacturing, procurement, maintenance and service.. Integrated revision and change management mechanisms ensure that all changes are meticulously tracked, maintaining data integrity and supporting efficient change processes.

Explore the capabilities of xBOM and see how it can transform your BOM management.

REGISTER FOR FREE to try OpenBOM and experience the power of xBOM and its robust revision management system.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.