In today’s rapidly evolving digital landscape, businesses across industries are racing to embrace the concept of digital transformation. At the heart of this transformation lies a shift from traditional document-based approaches to data-centric strategies. This paradigm shift is not only crucial but also offers immense benefits in terms of efficiency, collaboration, and scalability.

At OpenBOM, we look at the transformation as an opportunity for manufacturing companies to become more efficient and to build a center of engineering and operation intelligence around product data. Knowing every small detail about the product, components, suppliers, cost, and many other characteristics of the product provides a superpower to every manufacturing business.

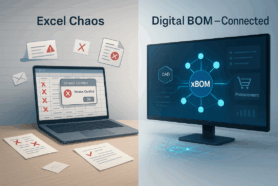

But the reality of many manufacturing companies is ugly – many CAD files, spreadsheets, and other documents that are held by different file services and personal computers. To make the transformation happen, companies need to find a way how to absorb existing documents and transform the data from these documents into valuable data assets.

To lead the transformation, OpenBOM recently introduced OpenBOM Design Projects, a powerful service to manage all documents and files using cloud services. It includes a very simple Project-based data management paradigm, using the existing flexible and powerful OpenBOM data model, and allows all manufacturing companies to load their document with an unlimited number of projects and files. Here is why it matters and why we do it.

Placing Data “in the Middle” of Digital Transformation

The digital transformation wave is all about harnessing the power of data. Companies are realizing that data is not just a byproduct but a valuable asset that can drive informed decision-making. To achieve this, data must be at the core of every process, and this is where the concept of placing data “in the middle” becomes pivotal.

Traditionally, data existed in documents, which were often scattered across various systems, making it difficult to access, analyze, and utilize effectively. By placing data at the center of digital transformation, companies can create a single source of truth, enabling seamless data flow, collaboration, and insights.

Challenges of Data Management Habits and File Dominance in CAD Tools

One of the major hurdles in transitioning from documents to data is the deeply ingrained habit of managing information through files, especially in fields like engineering and design. Engineers and professionals are often resistant to change, as they have relied on file-based systems for years.

CAD tools, in particular, have dominated the engineering landscape, and engineers have become accustomed to managing their designs through files. However, this approach can lead to version control issues, data duplication, and collaboration bottlenecks.

Cloud, Multi-Tenant Architecture, and Elasticity

OpenBOM addresses these challenges with its cloud-based, multi-tenant architecture. This architecture not only provides the flexibility and scalability needed to manage vast amounts of data but also ensures data security and accessibility. Whether you’re a small startup or a large enterprise, OpenBOM can adapt to your data needs.

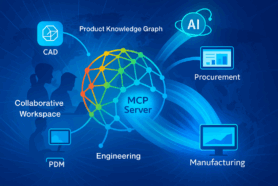

The foundation of OpenBOM is a flexible data model built on a scalable application platform using modern data management systems. It includes NoSQL and Graph Databases that provide scalable alternatives to old-fashioned PLM object modelers built around SQL databases.OpenOM data platform provides real-time flexible data models, multiple degrees of data model adaptation, and multi-tenant data management. It scales globally using cloud providers such as AWS and others. It can be deployed in the public cloud but also can be used in local cloud accounts by large OEMs and their suppliers.

Resolving the Pain of File Management – For Free

To facilitate the transition from documents to data, OpenBOM offers an innovative and simple solution – OpenBOM Design. It allows users to sync their folders with files to design projects, taking control of their data. The best part? It’s absolutely free. This eliminates the pain points of file management and simplifies data organization.

Information Flow and Connecting Silos

OpenBOM excels in capturing data automatically and connecting engineering to production and procurement through its unique collaborative technology. This seamless connection streamlines processes, manages changes, and streamlines approvals, breaking down information silos.

Pulling More Data Value and Data Science

As data takes center stage, businesses can harness its potential to derive actionable insights. OpenBOM Design provides advanced dashboards that enable businesses to extract more value from their data. This includes features like item management, purchasing intelligence, change impact analysis, and cost comparison, among others.

Conclusion

The ultimate goal of embracing data-centric strategies is to empower manufacturing companies to manage their processes more efficiently using data intelligence. OpenBOM Design offers a clear path to achieving this goal. By first addressing the challenges of managing files, then transitioning to product data, and finally unlocking the potential of intelligent data, OpenBOM paves the way for a more streamlined, efficient, and data-driven future in manufacturing.

In a world where data is the new currency, OpenBOM Design offers the key to unlocking the vast potential that lies within your organization’s data, all while providing unlimited storage for free. It’s time to move from documents to data, and OpenBOM is leading the way.

REGISTER FOR FREE to learn more about how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.