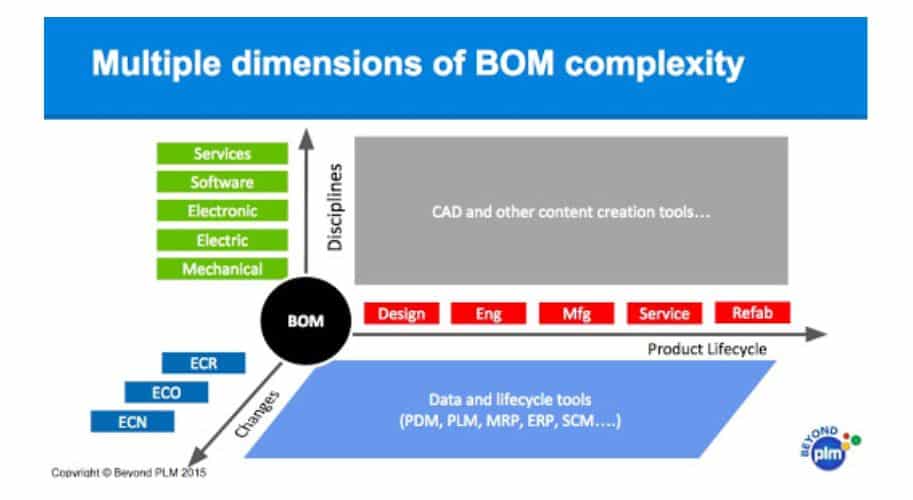

Modern products are complex and include mechanical, electromechanical, electronics and as of late, a lot of software. All together, it creates a big challenge for data management and, most importantly, change management disciplines.

History of BOM and PLM solutions – Silos

Historically, PLM tools were coming from CAD disciplines and products (MCAD, ECAD), and software product configuration management tools were not connected to mechanical and electronic development. It created a big silos of configuration management.

You can see tools capable of handling changes in mechanical assemblies, but rarely touching PCB design and not including software at all. This is a reality in many PLM implementations.

At OpenBOM, we’ve been thinking about the problem of multi-disciplinary teams and data from the early stages designing a flexible and multi-tenant data model capable of handling data from any discipline (MCAD, ECAD, Software) and also connecting the data between multiple teams and companies.

In my Beyond PLM article back in 2015, I published this diagram, which represents multiple dimensions of BOM complexity.

PLM systems by far failed to manage multi-disciplinary product structure because of the silos, which provide the biggest challenge for the data modeling, change management and collaborations. However, multidisciplinary BOM has both technical and political challenges. Check out more in this article – PLM and ERP – separated by a common Bill of Materials.

In my article today, I will talk about how OpenBOM technologies support multidisciplinary product development and change management that is much needed for modern product development.

Multi-Disciplinary Product Structure (BOM)

OpenBOM’s product structure is completely neutral and flexible. You can read more about OpenBOM reference-instance relationships and product-structure hierarchy relationships in the OpenBOM Training Library.

The model allows you to have distributed catalogs to represent a classification of item’s data, which is not only flexible, but also shareable between multiple users, teams, and companies if needed. This gives maximum flexibility to the data that can be managed by OpenBOM.

Each catalog item can be configured with a flexible set of attributes (properties) to represent different items – hardware, electronic, software and others. Ad-hoc relationships capture allows you to build product structure from different items as well as combine existing Bill of Materials. OpenBOM simultaneous and collaborative data management allows multiple people and teams to work together on this structure.

CAD add-ins and other Integrations

OpenBOM CAD add-ins and other integration capabilities (import and REST API) allow seamless import of data to fuse it in a single multi-disciplinary structure combined from Mechanical BOM, Electronic BOM, Software BOM, and other elements.

The key in achieving this structure is a flexible and collaborative data model allowing granular definitions of data, ability to share data between multiple teams and companies as well as visualize the data. All these functions are enabled by modern data management methods and database technologies.

Revisions, Change Management and Lifecycle

OpenBOM revision model described in the previous article and also in the OpenBOM training library, gives you a flexible and granular way to manage history of changes, immutable snapshots in multi-disciplinary structures.

Each level of the multi-level product structure is capable of holding its own set of revisions. In addition, OpenBOM revision propagation mechanism allows to push/pull revisions in both top-down and bottom-up change management logic.

Next Steps

In case you’re wondering, we are far from being done! Current OpenBOM revision and change management mechanisms are used to manage a multi-disciplinary set of data coming from multiple data sources – mechanical, electronic, software. You can download CAD add-ins, import Excels and start right now to manage multi-disciplinary data sets.

We are making continuous enhancements to the way we support flexible multi-disciplinary product structure as well as changing management orchestrations. Stay tuned for item/catalogs revision history and routing features combining multiple changes coming later this year.

Conclusion

The foundation of OpenBOM is a granular and distributed data management system allowing not only the flexibility in data structure, but also the advantage of multi-tenancy including data sharing and collaboration between users, teams and companies.

In my coming articles, I will bring you a few practical examples of how distributed data management and collaboration can help manufacturers organize the lifecycle of products and answer the most critical aspects of product lifecycle management in the 21st century. Stay tuned…

In the meantime, Register for FREE to check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.