Collaboration is a key to success in modern manufacturing. Companies are hiring the best talents globally and working with the best contractors and suppliers in the world. Manufacturing facilities are often located close to consumers and supply chain networks are global too.

Excel and email are bad collaboration tools. To support such a level of distribution and to stay connected manufacturing companies need to have the next generation of software to support such processes. In our everyday experience, we can see engineers and manufacturing companies go through the process of BOM Excel Detox. OpenBOM provides a unique technology to share data and collaborate. The technology allows seamless connection between teams by sharing data on a granular level.

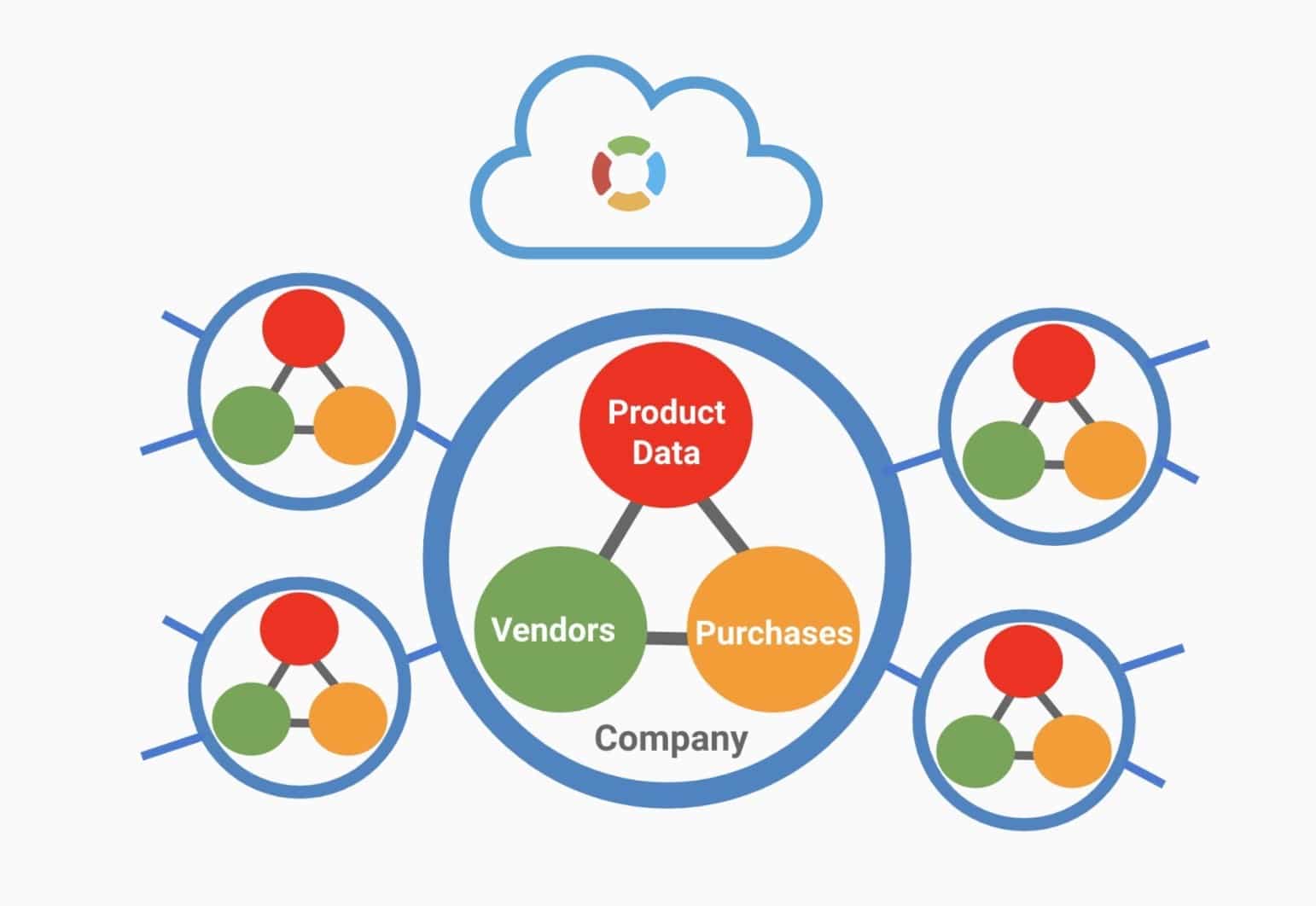

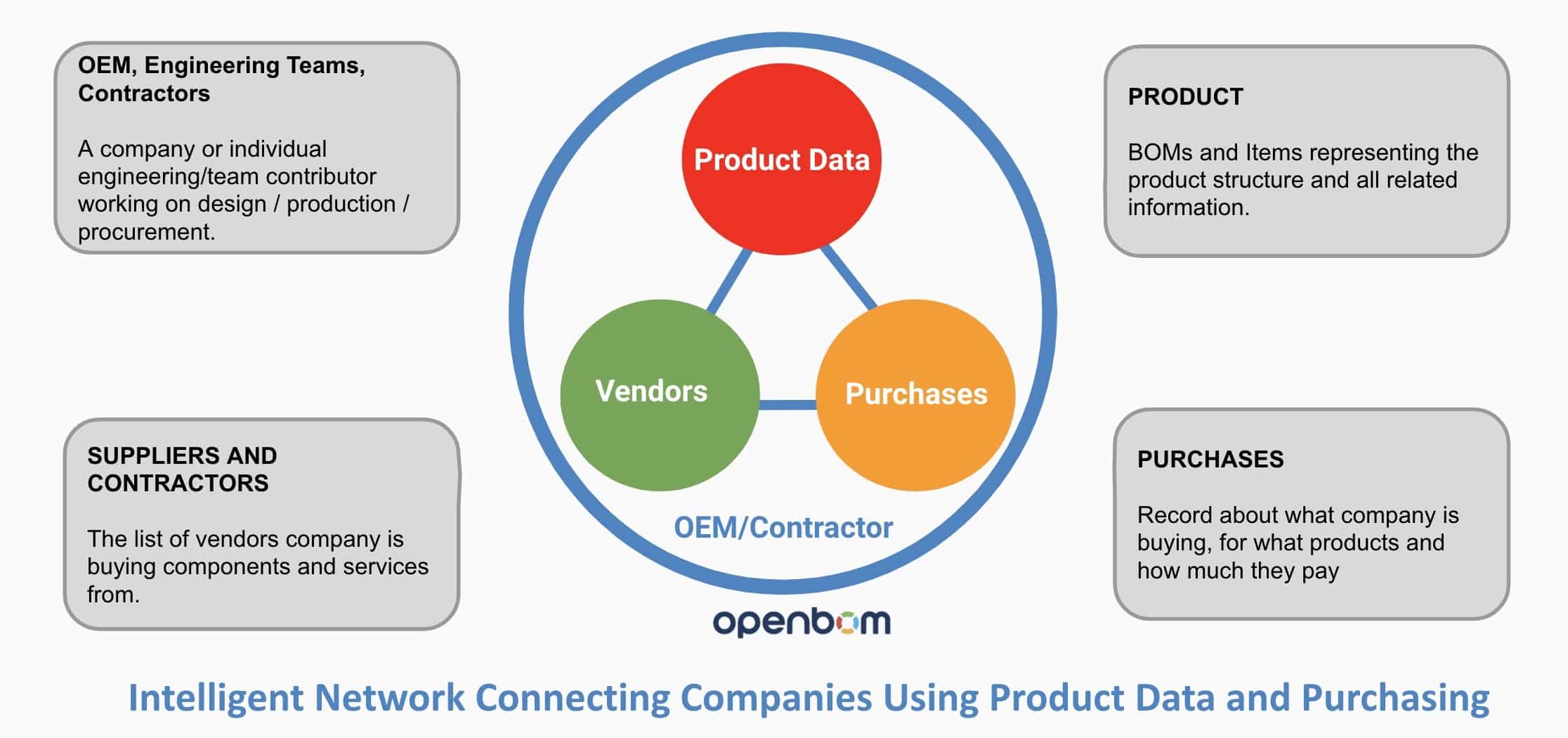

In my article today, I want to talk about three main elements of OpenBOM data networks: Product Data, Vendors, and Purchases.

Product Data

The foundation of the OpenBOM data platform is data. OpenBOM provides flexible data objects to define items, bill of materials, orders, vendors, purchase orders. Using structured data properties and relationships, OpenBOM supports core product information data modeling and semantic relationships between data elements,

Instant data sharing combined with user-defined team views is a foundation of the data-sharing mechanism. Data can be shared with the maximum level of granularity. Learn more about OpenBOM data sharing and collaboration.

Vendors

OpenBOM allows you to capture, import, and manage vendor lists. Vendors can be anybody the company is doing business with. Every item in the OpenBOM catalog can use one or multiple vendors to perform orders and purchasing.

Purchasing

Order BOMs is a foundation of production planning. OpenBOM supports the management of purchase orders and RFQ based on the manual or batch planning functions. Supported bottom-up, the purchasing functions use the foundation of product data and vendors connection to facilitate the ordering process.

Conclusion

OpenBOM provides a unique multi-tenant data management platform that allows engineering teams and companies to connect and work together. The process combined data sharing and building relationships between manufacturing companies, suppliers, and contractors based on the business relationship such as collaborative work and purchasing. OpenBOM provides access to a granular set of product information, connects contractors and suppliers as well as supports the ordering of materials and outsourced contractors’ work.

Learn more about what OpenBOM can do for you – register free, gets 14 days of the free trial, and check it by yourself.

Best, Oleg

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.