SaaS is changing the way manufacturers operate. Going back 10-15 years, we’ve seen a very conservative enterprise software stack. Enterprise apps were delivered by software vendors on CD ROMs in FedEx packages, which required installation, configuration, and services on site. Enterprise software such as PLM, ERP, MES was expensive, required long adoption cycles and complex support by internal teams. Things are going to change now and the industry is on move towards a new tech stack.

Moving Industrial Stack Towards SaaS

Cloud and SaaS are already changing the industry. For the last 10 years, industrial companies of any size adopted SaaS software and used it for CRM, marketing, and sales. Now it is coming to operation, engineering, and manufacturing.

By delivering software as a service, instead of licensing and installing it on-premises, SaaS allows companies to take advantage of the latest technology without significant investment in hardware or staff. This shift is creating a new manufacturing stack, which includes private cloud infrastructure, enterprise resource planning (ERP) systems, and product lifecycle management (PLM) tools. To stay competitive, businesses must adopt this new stack to take advantage of its agility and scalability.

For manufacturers, the age of Industry 4.0 is both an exciting and daunting prospect. The potential for increased efficiency and reduced costs is certainly attractive, but the upheaval of business processes and technology infrastructure that such a transformation would require can be understandably daunting.

In today’s blog, I’d like to explore how cloud-based software as a service (SaaS) can help reduce the cost and complexity of transitioning to a new manufacturing stack. We’ll also look at some of the most important considerations when making this transition.

Developing New Paradigms

Nothing holds us back stronger than existing paradigms. The trajectory of engineering and manufacturing software development went from how to make it faster, cheaper, nicer, and easier to adopt and implement. Nothing wrong with that. You can see the evolution of PLM architecture in my blog here.

However, that innovation in software for industrial companies is all about how to shift from corporate IT servers to cloud servers. That would be too narrow for a big vision of the future of the engineering and manufacturing business. The real difference is not where servers are located and how much they cost, but in the way, systems are working and provide value to businesses. So far, the biggest difference is how systems are interconnected, provide solutions to manufacturing eco-systems, and how the entire software stack works together.

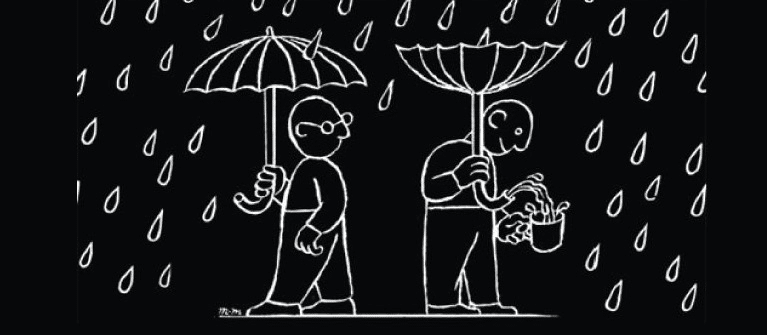

A few years ago, my attention was caught by Peter Hall’s tweet. The message is resonating – The difficulties lie not so much in developing new ideas as in escaping from old ones. Cloud technologies create a huge acceleration to think about new PLM development. However, as much as companies moved forward, old enterprise ideas kept the systems at the same place, and ideas deteriorated towards only using cloud servers instead of on-premise PLM installations.

From Silos to Connected Services

The old way of thinking was to have a database (or system) for each department or silo. Every department was about to optimize their workflows and therefore the system for each department looked like a data to manage data of the department and their workflow. This is how we end up with MRP, CRM, and eventually PDM/PLM too.

The problem with these systems is that they managed siloed information yet thinking about how to focus on information flow and how to get a value of the data managed by the company. Even more, these systems protected everyone outside of the company, so the data will not be shared with other companies and customers.

A new approach is to switch to online platforms and connected services. I will explain to you how it is different from everything you’ve been seen. In the age of online platforms, each one is focusing on a specific domain experience but provides services to many customers. There are two main reasons why it is becoming more valuable – connecting people and companies, getting value from the data and intelligence. And, it also allows optimizing the services these platforms provide by serving multiple customers.

So, instead of an isolated enterprise XYZ “management” system, we are getting platforms that are capable of providing services (no IT infrastructure is needed) and glean intelligence from the information companies are managing using these services.

Infrastructure and SaaS Stack

Technologies are important and can make a difference when you built highly scalable and intelligent platforms. In the past, all PLM or MRP vendors used Oracle or IBM databases. The reason was simple – the infrastructure was approved by IT, so everyone used it. These days, the infrastructure is managed by a vendor, so many other criteria are coming into play. Here are some examples of SaaS stack for modern software development.

Public Cloud Providers and Virtualization

Everything should run in some environments. These days IaaS platforms provide a comprehensive mechanism to provide computing, data storage, and management resources. You can go with Amazon Web Services, Google Cloud Platform or Microsoft Azure. The platforms give you a practically unlimited amount of resources to use as well as a good pool of people on the market to manage it. These platforms are managed by DevOps. Another aspect of the environment is virtualization services that disconnect you from physical machines and the need to be in a single environment. Building software in such a way can solve many problems.

Data Storage and Processing

Good data architecture is the foundation of everything else. Therefore, we decided on polyglot persistence and online DBaaS to manage data. You can pick open database solutions and host them online. This is what we do, we support multiple databases and virtualize the access to them via interfaces. Special databases can take care of specific data and we pull everything together using virtual services. Additional data infrastructure can be used to handle multiple data services – from temporary storage to analytics.

Services, components, and APIs

To develop robust applications these days doesn’t mean picking a single language and code for an entire system using these systems. Modern applications are using re-usable components that are exposing RESTfull services that can be used by other applications. So, a modern application is a bunch of services connected to perform specific actions.

Examples of Vendors

The transformation is not happening in a day. There are many software applications that companies invested money in. And we will be continuously focusing on how to keep existing applications and preserve the value combined with building new applications and services.

Engineering and manufacturing software services are having a new set of companies that are developing online platforms to manage data, collaborate and perform transactions. Here are a few examples of companies that are changing the paradigm…

- Onshape (a new paradigm of online CAD services)

- OpenBOM (a new paradigm of online PLM/PDM/MRP service)

- Tulip (a new paradigm of front-end operational /MES) software platform

Conclusion

It takes time to make a switch for even a very small company. Moreover, any change even from very bad business practices is also hard. At OpenBOM, we believe in data platforms, sharing, and collaboration as a fundamentally new tool of integrating and streamlining processes and knowledge across organizations.

REGISTER For Free and get a 14 day trial of OPENBOM to check out how our platform can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.