At OpenBOM we’ve helped many engineering teams start to organize their design and engineering data. OpenBOM helps to manage files, versions, item masters, BOM, and changes in a cohesive intelligent data set. The data is collected from multiple sources – CAD systems, Excel files, legacy databases, etc. OpenBOM makes it happen by multiple integrations and import functions available out of the box to all our customers.

OpenBOM CAD Add-in For SOLIDWORKS

SOLIDWORKS is the de-facto industry standard for mechanical design, one of the most popular MCAD systems, which is used by millions of customers in the world. One of the most important elements of OpenBOM Add-in for any CAD system including SOLIDWORKS is the settings that allow you to define all parameters to be used to extract the data from CAD system to OpenBOM.

Share SOLIDWORKS Add-in Settings With Your Team

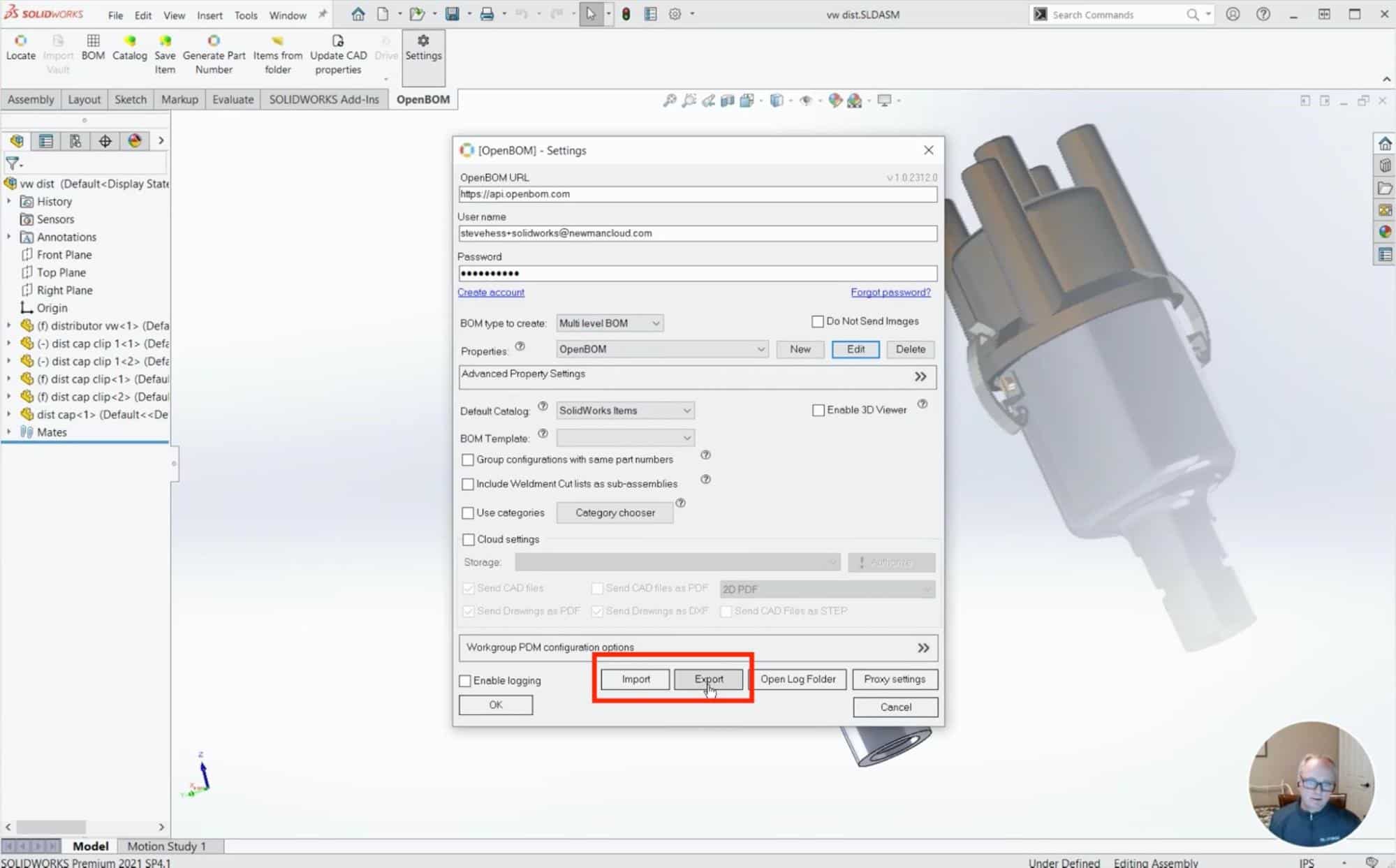

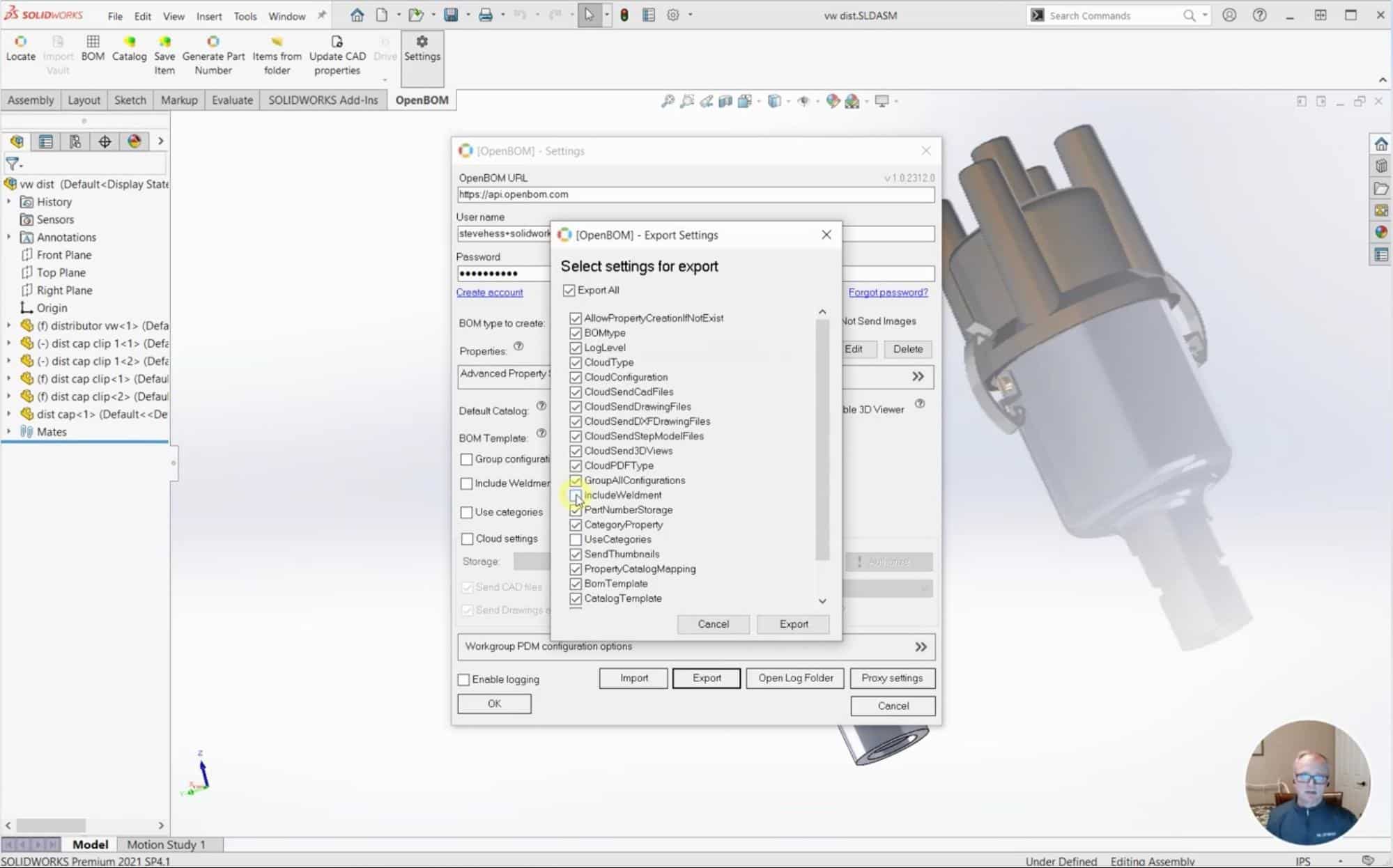

OpenBOM allows you to select multiple parameters defining what data will be exported. These parameters include a list of properties from SOLIDWORKS, various options such aas Exclude from CAD, Configurations, Weldments, Cloud settings (what files to upload to the cloud), and many others.

We found that management of these settings can be a painful process (especially when you need to copy the same set of settings for many users). I’m super excited to share that we just introduced a new feature allowing you to share these configurations with your team.

The mechanism of sharing SOLIDWORKS Add-in settings allows you to export these settings in the external file and import them into another user account.

Video Demo

In the following video, we demo the process of how you can export OpenBOM SOLIDWORKS add-in settings to an external file and import it to another user. Keep in mind, we won’t export users and passwords, so these settings can be created once and shared by the team.

Conclusion

At OpenBOM we think about productivity and how we can help you set up and implement the system as fast as possible. We recognized the importance of sharing settings and how it can speed up implementation for larger customers.

P.S. Thanks to customers that brought this feedback to us. If you have something you want to improve in OpenBOM, please let us know – we would be happy to discuss it.

REGISTER FOR FREE to check out how OpenBOM can help you and your team today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.