In today’s fast-paced industrial business landscape, any development team is under increasing pressure to bring innovative products to market quickly. Every manufacturing company we speak to is looking at how to move fast and build better products at a lower cost. It is easy to say, but much harder to do. Product development is brutal and requires a team effort. A single person can make the best design, but won’t deliver it on time. An innovative product can fail to scale because of DfM (design to manufacturability) issues. Late delivery of supplied parts can cost penalties and loss of customers.

The ability to rapidly develop and launch new products can provide a significant competitive advantage for any development team, allowing companies to stay ahead of the curve and meet ever-evolving customer demands. How to achieve that? In my series of articles about New Product Development this week, I want to tell you how OpenBOM makes it happen and helps many OpenBOM customers from very small companies to large enterprises to work more efficiently and to accelerate their new product development (NPD) processes.

The Chain is Only as Strong as Its Weakest Link

In the domain of product development and manufacturing, the adage “the chain is only as strong as its weakest link” holds tremendous significance. The success of bringing new products to market depends on the seamless coordination and collaboration between various departments. One of them are standing out in particular engineering and procurement. We learned from many OpenBOM customers that the disconnect between these two critical functions can prove costly, both in terms of financial resources and time.

The Engineering-Procurement Divide

Engineering and procurement are vital pillars in the product development and manufacturing process. Engineering teams design and develop the product, focusing on functionality, performance, and quality. Procurement and supply chain teams, on the other hand, are responsible for sourcing the necessary materials, components, and services needed to bring the product to life. Both functions are interconnected and interdependent, yet their misalignment often results in significant setbacks.

The disconnect between engineering and procurement is costly and painful. When engineering and procurement fail to collaborate effectively, companies face substantial financial and temporal repercussions. Firstly, there is a risk of procuring components or materials that do not meet the engineering specifications, leading to defective products, rework, or even product recalls. Such errors can tarnish a company’s reputation, result in customer dissatisfaction, and impose significant financial liabilities.

Secondly, inadequate communication between engineering and procurement often leads to inaccurate or incomplete procurement planning. This can result in delays, as procurement struggles to acquire necessary materials and components on time, causing production bottlenecks. Late deliveries, rushed sourcing decisions, and reliance on expensive expedited shipping options can inflate costs, eroding profit margins, and compromising the overall project timeline.

Digital Thread – Connecting Engineering and Procurement

Synchronizing Engineering and Procurement: To avoid the costly pitfalls of an engineering-procurement disconnect, organizations must foster collaboration and communication between these departments. Here are a few key strategies to bridge the gap:

- Early Engagement: Involve procurement and supply chain professionals in the product development process from its inception. Their expertise can help identify potential sourcing challenges, explore alternative materials or components, and provide cost and lead-time estimates.

- Shared Data: Implement integrated systems and tools that allow engineering and procurement teams to access and update information in real-time. This ensures visibility and transparency, enabling proactive decision-making and rapid response to changes in design, specifications, or sourcing requirements.

- Seamless updates and real-time inventory control: To achieve maximum efficiency, engineering and procurement activities must be interconnected using fully integrated data management tools. Capturing design information must be seamless and doesn’t require manual updates. Information about procured parts, suppliers, lead time delays, and PO must be seamlessly connected together to ensure on-time delivery.

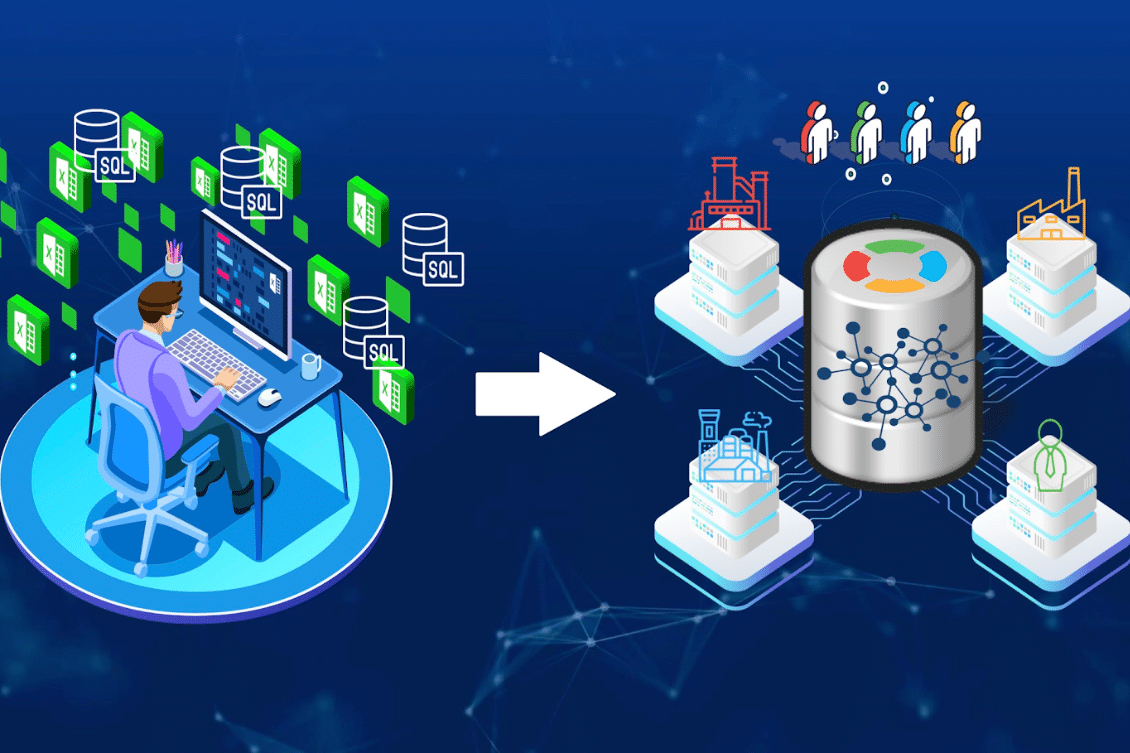

Engineering and Procurement Silos

The reality of many product development teams from very small to large enterprises is amazingly similar and represented by the following three characteristics.

Design Tools and Excel Export Habits

Product development teams are complex and modern product development is multi-disciplinary, and it requires the involvement of people from different specialties – mechanical engineers, and electronic and software specialists. While all of them are focusing on how to make the best design, a simple function such as procurement and supply chain is always an afterthought. When it comes to communication, Export to Excel (or Google Sheets) is the best that you can get, which is sent to the procurement team often late and often contains mistakes.

Small Batches, Prototyping, and Inventory Control

Building a product requires physical parts. Some of them must be manufactured, but many of them are purchased – materials, components, and outsourced assemblies. Keeping track of the process of procurement is a separate job, which is usually separated from engineering. But here is the problem – without accurate data from engineering, a procurement is blind, deaf, and lame. They depend on the information from engineers that usually comes late and includes many mistakes. Communicating using spreadsheets is a mess, updates are costly and inaccurate.

Change Management and Cost Estimation

These two elements of the new product development activities are the most painful. Because of silos, the data is disconnected, and making changes is between hard and impossible. On the other side, the cost is also near impossible to predict and calculate because none of the silos contains accurate information about the product plan and up-to-date supply chain and procurement data. Playing “what if” scenarios is impossible.

OpenBOM – Agile New Product Development Digital Thread

OpenBOM provides an integrated environment where engineers, procurement planners, and supply chain specialists can work together regardless of their location, tools, and time. The idea of Minimum Viable Digital Thread focuses on connecting people, processes, contractors, and suppliers to facilitate faster iterations and eliminate manual data re-entry.

- Stay on the same BOM and Inventory Data: Agile product development and methodologies have revolutionized the software development industry by emphasizing iterative and collaborative approaches to project management. This mindset has found its way into new product development as well, enabling companies to respond swiftly to changing market dynamics and customer feedback. Agile new product development involves breaking down the product development process into smaller, manageable chunks called sprints. At OpenBOM, we allow engineers and procurement to come closer and share data instantly. Integration with CAD tools, and management of digital BOM combined with integrated inventory control to support batch planning are key to making it happen. Everyone stays on the same BOM and has visibility on the product design and procurement process.

- Connecting People and Processes: To expedite new product development, it is crucial to connect various stakeholders involved in the process. This includes internal teams within the company, as well as external contractors and suppliers. By leveraging digital tools and platforms, companies can establish seamless communication channels that foster collaboration and information sharing. This connectivity enables real-time feedback, reduces delays caused by manual handoffs, and ensures everyone works towards a common goal. OpenBOM instant data sharing technology and real-time collaboration and sharing are here to help.

- Iterating Fast: Traditional product development cycles can be time-consuming, often involving lengthy design phases, prototyping, and multiple iterations. However, with the agile approach, companies can reduce the time to market significantly. By providing tools seamlessly integrated with CAD, extracting data, and sharing it, companies can move fast and repeat as soon as they need. Connectivity is key. This iterative approach allows for continuous building, testing, learning, and refinement, leading to faster innovation and a higher probability of launching successful products.

- No Manual Data Re-entry: One of the primary hurdles in new product development is the manual re-entry of data across various systems and departments. This not only consumes valuable time but also increases the risk of errors and inconsistencies. Each time you re-enter your Bill of Materials between Excel, CAD systems, and purchasing tools, your team creates potential mistakes. The Digital Thread OpenBOM created aims to eliminate this manual re-entry by establishing a digital backbone that connects different stages of the product development lifecycle. This digital thread ensures seamless data flow from engineering to procurement, manufacturing, and beyond. With integrated systems, data is automatically shared, reducing administrative tasks and enhancing accuracy.

- Engineering-Purchasing Connected in a Digital Thread: A critical aspect of successful new product development is the seamless integration of engineering and purchasing functions. Traditionally, these departments have operated in silos, leading to miscommunication, delays, and cost overruns. However, by establishing a digital thread, engineering, and purchasing teams can collaborate effectively throughout product development. Engineering teams can provide real-time updates on design changes while purchasing teams can assess the impact on costs and availability of materials. This synchronized approach enables early identification of potential roadblocks, facilitates informed decision-making, and ensures a smooth transition from design to production.

Conclusion:

New product development in today’s fast-paced business environment demands agility, connectivity, and the efficient use of digital technologies. OpenBOM creates a Digital Thread between engineering and procurement and provides a framework for achieving these objectives. By embracing agile methodologies, connecting people and processes, iterating quickly, eliminating manual data re-entry, and establishing a digital thread between engineering and purchasing, companies can accelerate their new product development cycles and gain a competitive edge. Success in the market will increasingly depend on the ability to innovate rapidly and bring products to market ahead of the competition, making the adoption of these strategies and technologies essential for any organization seeking to thrive in the digital world.

Later this week, I will share more information about OpenBOM tools which can help you to accelerate the new product development process.

In the meantime, REGISTER FOR FREE and explore how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.