Talk to anyone in product development and manufacturing and they will agree with you about how bad and unreliable it is to use Excel (or other spreadsheets) for data management. I’ve been on this topic for a long time and I know how messy Excel-ware data management can be. I was talking to one of my engineering friends another day and he told me – everyone hates Excel, but not everyone is ready to walk the walk out of Excel.

Behind any product development process, there are tons of data. Your process is as good as the data you have. Otherwise, you make wrong decisions based on the wrong data and you don’t deliver on time. Excel is a lingua franca of many engineers and manufacturing companies to organize data and processes in a pre-digital world. However, it slows organizations down and allows them to make mistakes.

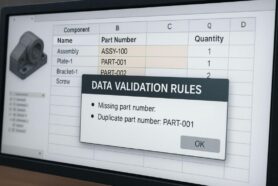

Here is what happens when you rely on Excel for data and process management:

- Your procurement team won’t have updated information about the parts required to order

- You will order the wrong parts

- You will order the wrong quantity of parts than what you need

- You will miss the optimal ordering time (based on lead time)

- Your building process will be delayed

- You will miss the promised shipment dates to your customers

- You will be late and your customers will get frustrated

What if you can organize the data to make the right decisions faster? How can organizations say – No More Excels and actually walk the walk to the world with No Excels?

5 Excel Replacement Challenges

Replace Excel. It is easy to say rather than do it. PLM companies were advocating for years to replace all Excel files and organize data and processes, but it didn’t happen. I was asking many engineers and manufacturing companies about that.

Here is what I learned:

- Engineers are afraid of complex and not intuitive PLM systems. The best you can see is a single license of the PLM system holds the data and everyone else pulls the data to Excel to do actual work

- It is hard to import data (eg. BOM, raw materials, and other pieces of information). Because of that, no one is ready to spend time on this while everyone has other priorities

- PLM systems don’t have a good reporting mechanism, therefore engineers and other people in manufacturing companies are afraid to get locked up in PLM systems.

- Many PLM systems are out of the box and don’t provide a flexible data model. As a result, they don’t allow easy to adjust the data model required, so not all data can be managed.

- PLM licenses are expensive, so many companies don’t have budgets and, as a result, they buy a 1-2 licenses and ask everyone else to use Excel to communicate

Smells like Excel, walks like Excel, and quacks like Excel, but it is not Excel

At OpenBOM, we decided to re-think the concept of a traditional PLM system and use a spreadsheet paradigm to develop a PLM data management system.

Behind the simple OpenBOM user experience, there is a robust and scalable data management engine using modern NoSQL and Graph Database. A patented collaborative user experience allows customers to share data simultaneously.

Last, but not least, the OpenBOM business model with concurrent licenses, allows optimizing usage of licenses and provide it to a wider group of users in the company, contractors, and suppliers without the need to buy a named license for everyone.

In addition to that, OpenBOM Integrations provides a simple way to import data. Out-of-the-box export to CSV, XLS, PDF, and ZIP file gives you an instant mechanism to export data and send it to anyone if needed.

Here is a short list of OpenBOM differentiators:

- Excel-like user experience

- Flexible data model

- Easy import/export

- CAD integrations

- Concurrent license model

All these characteristics make OpenBOM an ultimate candidate to force Excel out of any organization.

What Customers Say?

I captured 4 stories of OpenBOM customers to demonstrate how OpenBOM helps these companies to become more efficient, and save more money and time.

“We started as a small team dedicated to being lean and agile”, says Kenyon, “and we quickly learned that Excel and google docs did not meet our needs as our product structure spanned multiple engineering domains. The reliance on Excel also did not meet the company’s need to manage sub-assemblies.

“Even with a very capable team, and an extraordinary amount of effort, and many vlookup macros, Excel could not deliver what we needed, it was fragile and the logic would simply break”, Kenyon says.

“As the Nexa3D products matured we soon had a BOM administrator dedicating 20 hours a week to maintaining Excel BOMs. With OpenBOM we have no single admin. OpenBOM is largely self-sufficient, no dedicated IT person is needed. It just works.”

“As Puro Lighting grew, our Excel system was becoming unwieldy and dependent on too many templates and tabs, we couldn’t make a reliable BOM and could not reuse it to introduce a new product.”

“As we were ramping our products to manufacturing, we naturally had some changes, recreating these BOMs in Excel would have been very time-consuming. Knowing that our BOM references a single items list, we just make a change and the BOM or BOMs are automatically up-to-date.”

“Today, Puro Lighting has completely released products fully documented in OpenBOM.”

“Gates designed on hand drawings when we (my wife Karen and I) purchased the company in 2002. We immediately required different systems for design and inventory control, so we went to Solidworks and Excel. But as Gates grew, there came a point where we had too many spreadsheets, and none reliably interconnected. Our design and assemblies simply outgrew Excel.”

“OpenBOM helps us deliver effective metrology tools to our customers. When we started, we ran our builds on Excel”, says Hari, “with all the hardships that come with that, it did not scale. No images, no versions, no items, we outgrew Excel”; a relentless search found OpenBOM for OKOS; a trial run confirmed what seemed impossible; is there an Excel-like BOM flexible solution for a small manufacturer like OKOS – our search was “Excel AND BOM AND Cloud.”

The initial and running costs of the traditional ERP providers were a non-starter for OKOS, bloated solutions in wannabe cloud wrappers vs. a nimble design for Cloud.

“OpenBOM was an easy, frictionless, implementation for our engineers and assembly technicians. We did not need to read a lot of documentation or hire a consultant. It is a common-sense approach that fits nicely into our business.”

Conclusion:

OpenBOM focuses on a very painful problem that makes companies slow and inefficient – data accuracy. While Excel (and other forms of spreadsheets) lead companies to work with wrong and not updated information, OpenBOM brings everyone “on the same BOM” and allows you to use always updated information for all processes – design, production planning, purchasing, maintenance, etc. Combined with a user-friendly and affordable subscription model OpenBOM helps companies to leave Excel behind and build products faster.

Last, but not least… OpenBOM’s free registration and free 14-day trial period make it easy to register and try it out. Don’t wait, try it today and escape Excel forever.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.