During the new product introduction (NPI) process, you will need to make multiple prototypes. Unfortunately, some of these prototypes will fall short of your expectations. Also, during each phase of the development process, you will need to make prototypes. Depending on which phase of the NPI process you are at, the prototypes will yield different results. For example, the goal of the proof of consent (POC) sample will be different from the golden sample.

Samples can fail for several reasons. Usually, they fail for the following reasons:

- Failed functional tests

- Colors are not properly matched

- Your test market provided poor feedback

There are multiple other reasons why prototypes can fail but these are the most common reasons I have seen. Rather than freaking out that your prototype did not reach expectations, you should take the following steps.

Was the Prototype Made Correctly?

This sounds simple, but before changing up the design because the prototype failed, make sure it was made correctly. If it was a plastic part that failed, then you can ask yourself the following:

- What are the tolerances and can the prototype process meet those requirements?

- What materials are defined and what was the prototype made out of?

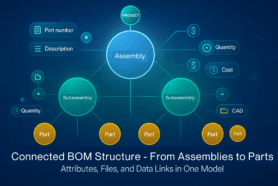

If it is an electronic component, make sure all components that were used are those defined in the bill of materials (BOM). Some suppliers might choose alternative components without telling you to save time during the chip shortage.

Design Optimization

If the prototype was made correctly but still failed then the design might have problems. Analyze first why the prototype failed and examine the design to see how you can make improvements.

As you proceed to later-stage development and get into the design for manufacturing and assembly (DFMA), you can leverage your suppliers and contract manufacturer. One of the tasks here will be to take you from a design that might have been focused on prototypes and optimize it for production.

Material Selection

Another common reason for a prototype to fail is because of incorrect material choices or because the supplier used the incorrect materials. You will need to educate yourself on which material you should be using.

Similar to the design, you can also leverage your supply chain partners to help you select the grades of material that are best suited for your design and application.

Alignment with requirements?

The most forgotten part of making a prototype is defining the requirements and the targets. Defining the quality standards of the part needs to align with what’s attainable for the materials and the machine for fabrication. If either one fails, you need to re-design the part for a different fabrication method or different materials.

How can OpenBOM help?

When you make a prototype, do you need to make changes to the product and worry about changing the BOM, drawings, revisions, and keeping everything organized? OpenBOM is your single source of truth to manage all of your engineering and manufacturing data, including your change and approval process.

Register for FREE to create your OpenBOM account and reach out to us via support @ openbom dot com if you have any questions.

Best, Jared

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.