The manufacturing industry is going through a major transformation these days. There is significant pressure on OEM to change their business models and transform companies from being totally focused on product development into companies focused on providing services to their customers. There are many examples of how this business transformation can go. One of the possible ways is to re-think business models and what actually companies are selling.

In a traditional model, companies build products and sell these products to customers. But, we can see many examples when companies are actually selling not products but services (eg. miles instead of tires, energy instead of turbines, etc.). Another example of business transformation is to focus on margins from spare parts.

Many credible analyses point out that after-sales margins from maintenance (eg. spare parts and service) can be 2-3 times larger and more predictable compared to the revenue from original products sold by OEM. According to McKinsey research, OEMs may find untapped goldmines in aftermarket services by strengthening their core business in parts, repair, and maintenance. Here is an interesting passage:

When exploring aftermarket value pools, industrial OEMs are often tempted to prioritize data-driven advanced services enabled by digital innovation and the Internet of Things (IoT). For instance, many hope to gain a competitive edge through e-commerce platforms and increased automation—digital strategies that are already common at B2C companies but less developed in B2B. OEMs may feel more pressure to develop digital capabilities than most B2B players because digital natives have recently entered the industrial aftermarket, offering parts and services at low prices.

You can ask how is it connected to BOM management and to OpenBOM? Let me give you some examples based on how OpenBOM is used today and the opportunity to expand it in the future.

A fundamental part of every data initiative in manufacturing companies includes the Bill of Materials as a source of data about the product, its parts, and related information. In the beginning, it is only engineering information (so-called Engineering BOM). However, as the company is moving forward, the information is transformed into the so-called As-Build, As-Planned, and As-Maintained status.

The last one is the most interesting because it contains the information in the way it can be exposed to the customer, sales and service teams. It contains not only relationships with parts, but also documents and process instructions. The flexible data model of OpenBOM as well as integrating with cloud storage makes OpenBOM an ideal solution to build OEM’s digital initiative.

OpenBOM is multi-tenant data management system, which means it has an embedded mechanism of sharing information between multiple companies (in this case it is OEM, service companies, dealerships, and other contractors). OpenBOM provides an easy way to share information from initial engineering and manufacturing phases to after-sales and maintenance.

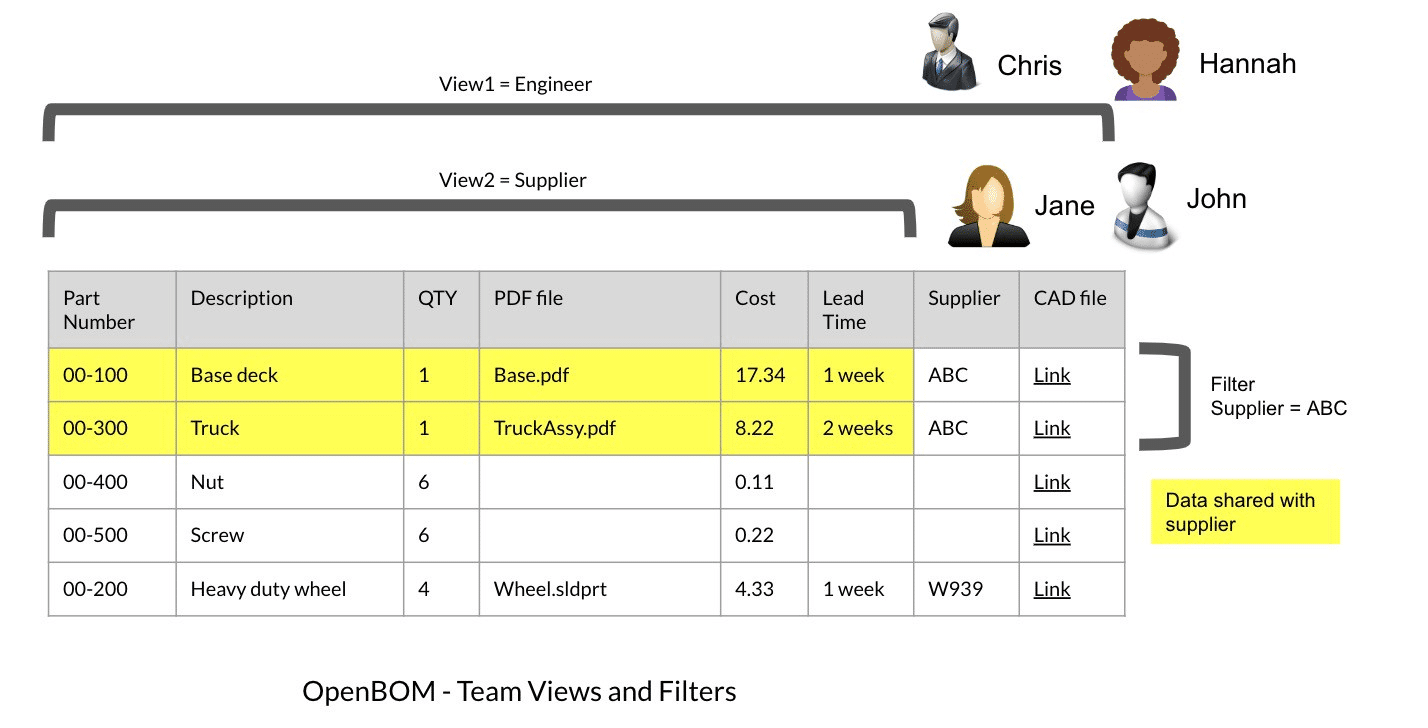

OpenBOM Team Views mechanism allows dynamic data sharing of information in such a way it will eliminate the need to export data and move it between multiple systems. It increases data quality and provides insurance that customers will be actually ordering a correct part from OEM for maintenance purposes. Imagine how much saving in time and cost in spare parts distribution mechanism it can provide.

The following picture gives you an idea of what is OpenBOM Team View mechanism.

In the following video, you can see a very short demo of how OpenBOM user-defined view can filter and present only “service” parts from an entire Bill of Materials.

Conclusion.

Modern digital technology provides an opportunity to transform business of manufacturing companies by streamlining processes and information to facilitate sales. In my example, I demonstrated how OpenBOM digital technology can improve the maintenance and service part ordering process by organizing information and sharing it with customers. OpenBOM online data management technology can be integrated with manufacturing company service and web infrastructure to integrate information delivery.

Want to learn more about how OpenBOM can help in your digital transformation projects? Please reach out to me via oleg at openbom dot com.

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Try OpenBOM today by registering to FREE OpenBOM User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.