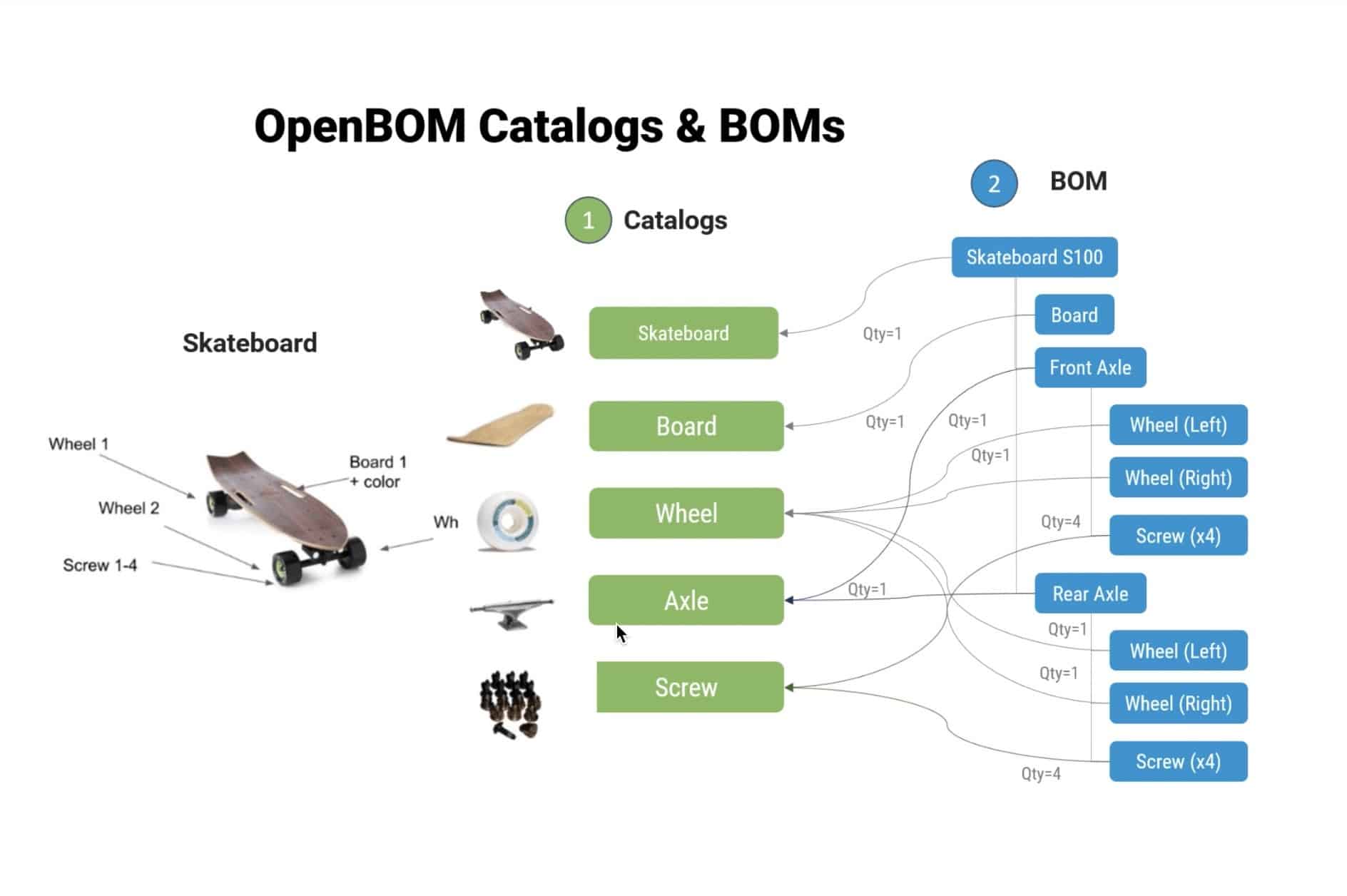

In this OpenBOM 101 video, you can get an idea of how OpenBOM manages data about Items (Parts, Materials, Assemblies) as well as Product Structures (Bill of Materials). OpenBOM fundamental data objects are items, catalogs, and the Bill of Materials. In the following picture, you can see one example of the relationship between Catalogs and BOM.

Items and Catalogs

An item (or configurable item) represents that information about engineering and standard parts. Everything goes here- standard components, materials, assemblies, labor, etc. Anything you use in your product must have an item (reference) stored in the OpenBOM catalog where you can add any piece of additional data using OpenBOM properties. This mechanism is super flexible – you can add anything you need. Catalogs. Think of catalogs as a classified library of all items. The catalogs are flexible and you’re not limited in the number of catalogs you can create in OpenBOM.

Bill of Materials (Product Structure)

A BOM (Bill of Materials) is a hierarchical data structure, which represents instances of all items in your product. Think of the following diagram shows how items can be instantiated and represent the product structure of the assembly. You can manage instance or quantity BOM in OpenBOM. OpenBOM is absolutely flexible and allows you to add custom properties on the instance level. Catalog items can be reused in BOMs, and you can add additional information to the Catalog items in the BOMs, such as quantity or reference designation.

Check the video on how you can manage and access the information in OpenBOM.

Also, check a longer video where you can see how to create items and BOMs for the first time.

Conclusion

OpenBOM is an online (SaaS) platform, which provides a way to manage product information. The foundation of OpenBOM is the reference instance model, which organizes Items (References) and their instances into a product structure (BOMs). OpenBOM provides a super flexible data model that allows you to extend the data to includes all attributes on both item and instance levels. OpenBOM metadata (properties) allows different types (number, list, reference, currency, etc.) which makes it an ideal way to represent product information

Register for FREE and check by yourself how OpenBOM can help you.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM. To find out about the PLM basics, you can check the Product Lifecycle Management article where we provide crucial information, examples, and describe main benefits.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.