In the last few years, the buzz surrounding artificial intelligence (AI) has reached a high level. The adoption of tools like ChatGPT and some others is skyrocketing. From self-driving cars to virtual personal assistants, AI is rapidly transforming the way we live and work.

All people I know working in manufacturing are scratching their heads and thinking about how AI technologies can be contextualized and help product development, design, engineering, production, supply chain and many other manufacturing related disciplines.

At OpenBOM, we’ve been digging into the AI landscape, conducting research, and identifying areas where AI can make a significant impact for our customers. In this blog, we’ll explore three key problems AI can help address in the manufacturing industry.

Finding Costly Mistakes in Bills of Materials (BOMs)

Mistakes in bills of materials (BOMs) can be incredibly costly, especially in the later stages of product development. These errors can lead to missing parts, incorrect supplier information, or inaccurate data, all of which can result in production delays, increased costs, and customer dissatisfaction. Identifying and rectifying these issues early is crucial. AI can play a significant role in automatically scanning and analyzing BOMs to detect discrepancies, ensuring that the data is accurate and up to date. This not only saves time and money but also enhances product quality.

Streamlining and Accelerating New Product Development

Creating an accurate BOM for a new product can be a complex and time-consuming process. It involves considering order specifications, configuration requirements, and various other characteristics. AI-powered tools like “BOM co-pilot” can significantly expedite this process by automatically generating BOMs based on the given parameters. This not only reduces manual labor but also minimizes the risk of errors, ensuring that the BOM accurately reflects the product’s requirements.

Supply Chain Optimization

Managing the supply chain efficiently is a perpetual challenge for manufacturers. Identifying reliable suppliers and avoiding problematic ones can be a daunting task. AI can be a game-changer in this aspect. By utilizing AI algorithms, manufacturers can automate the process of supplier evaluation and selection. AI can analyze supplier performance data, track delivery times, assess quality, and even predict potential supply chain disruptions. This level of automation can lead to significant cost savings and improved supply chain resilience.

The Foundation of AI: Data

While the potential benefits of AI in manufacturing is huge, the main conclusion we came to is related to DATA. Read my takeaways from the MIT AI Conference I attended earlier this year.

Without accurate and organized data, AI is nothing more than a technological concept. The first step in the creation of AI solutions is to have access to the right data. This is where OpenBOM comes into play. We understand how sensitive product information is for manufacturing companies and we are building mechanisms to bring this data to connect it to the best AI technologies possible. First to validate the concept and how it works, then scale it to different manufacturers.

How OpenBOM Can Help

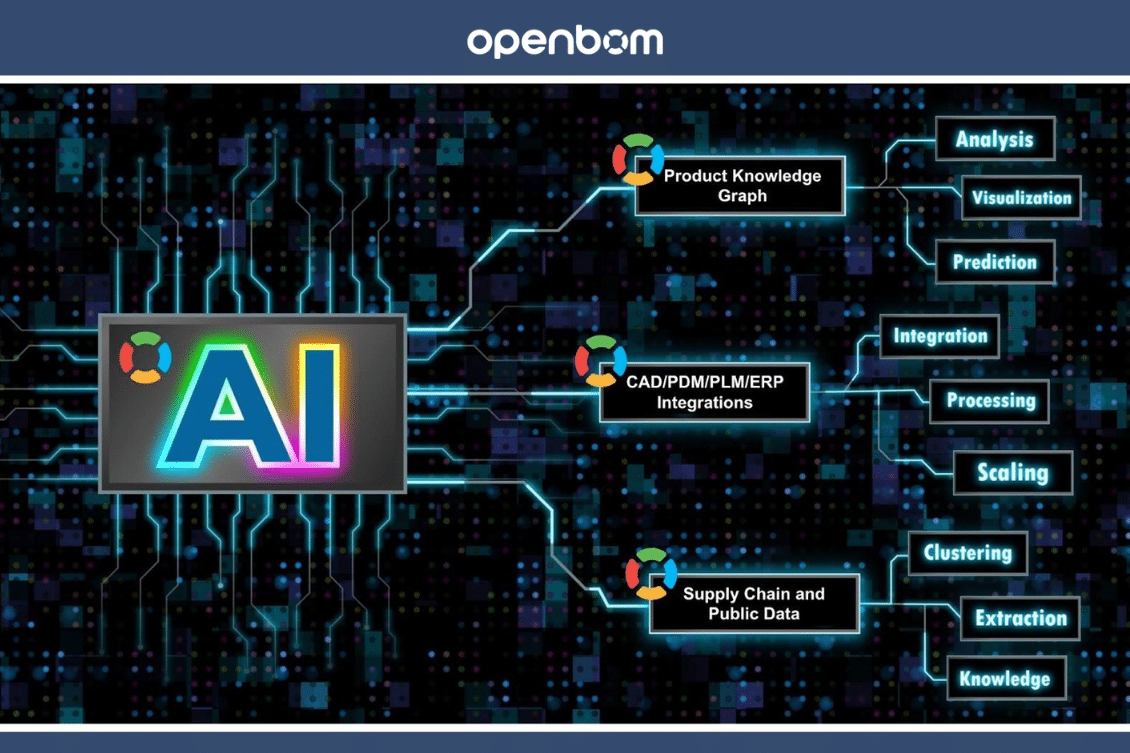

The core foundation of OpenBOM is pretty unique data management technology focused on how to gather product information from multiple systems, combine it together, get everyone in the company to work on this collaboratively and then push to the best mechanisms to create LLM (Large Language Models) to complement OpenBOM tools.

OpenBOM’s platform technology is designed to provide a multi-application and multi-tenant product knowledge graph, built using modern data management technologies and databases.

The use of a graph database enables the creation of a robust data foundation for AI applications. OpenBOM’s ability to integrate and centralize data from various sources is another key element of its AI strategy. By connecting to all BOMs and related data, OpenBOM ensures that manufacturers have the necessary data to build and deploy AI solutions effectively.

Conclusion

When it comes to AI, data is the foundation of all innovation we need to build. For manufacturers looking to harness the power of AI to address challenges, optimize processes, and drive efficiency, having the right data is crucial.

OpenBOM’s platform technology, with its data management capabilities and integration capabilities, provides manufacturers with the tools they need to lay the groundwork for AI-driven solutions. Whether it’s finding costly mistakes, streamlining new product development, or optimizing the supply chain, OpenBOM and AI can work together to transform the manufacturing industry.

We are just at the beginning of the process of AI contextualization for BOM management, product development and automation. But it is clear to us that it all starts with data. And this is where OpenBOM puts the biggest focus on today.

If you’re interested in our research and want to become part of it and learn more, please contact us.

REGISTER FOR OPENBOM and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.