I had a great honor to present at ConX19 – event organized by the Institute for Process Excellence. Check out more about the event on the website. In my presentation, I was sharing what is my perspective on digital transformation in engineering and manufacturing software.

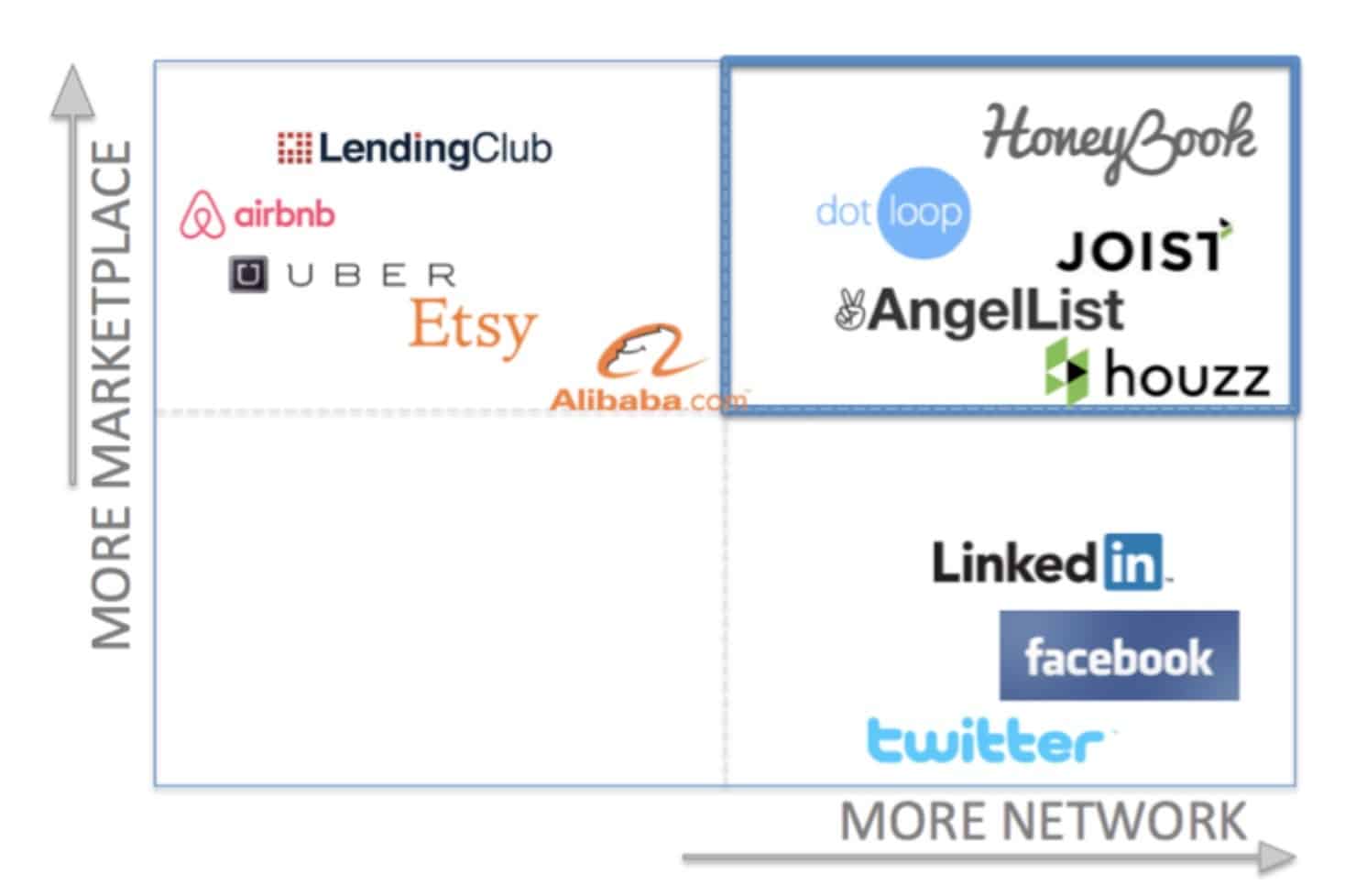

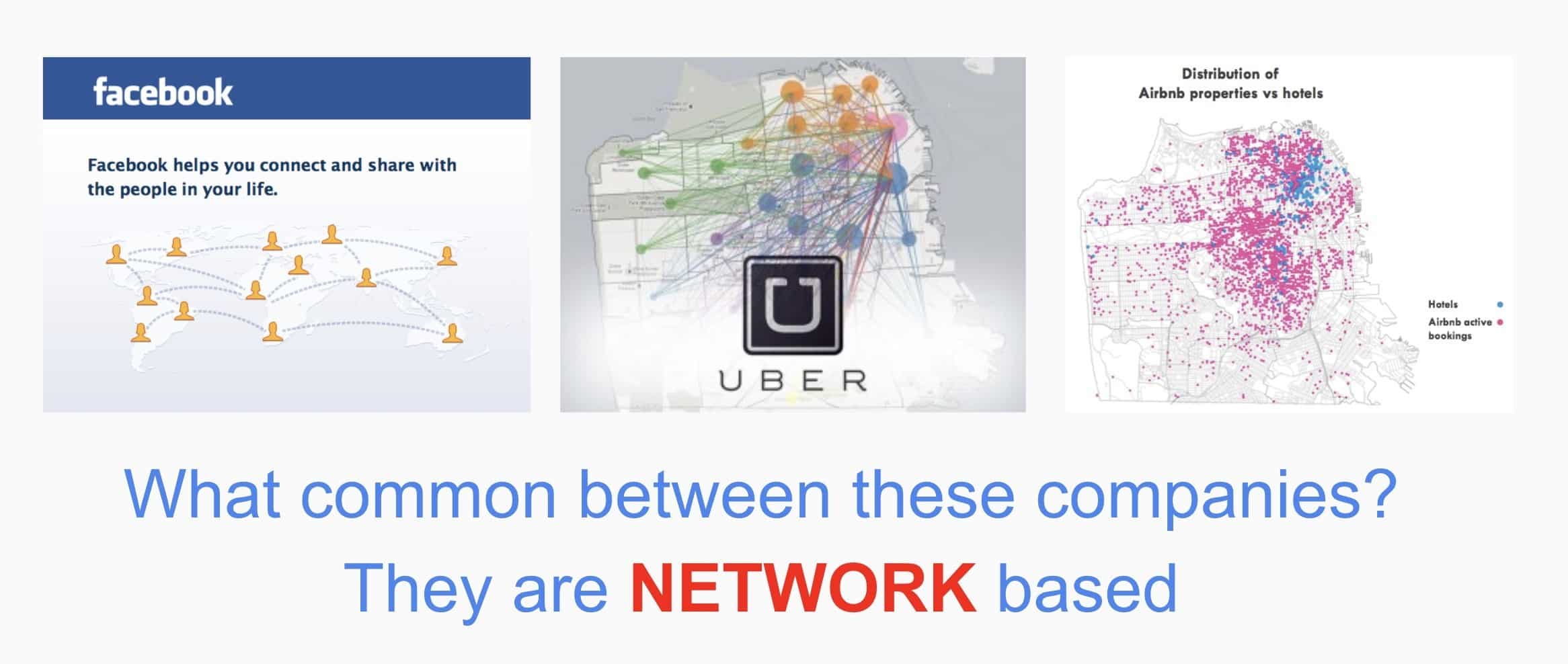

As an industry, we are at a very interesting point in time and change management. The last two decades demonstrated the power of digital transformation and networks. Digital platforms are changing the way we live, connect, do shopping and travel. The results are amazing.

All these new platforms have one thing in common – they are all network-based. Which means they connect people and product, they use the marketplace and other online mechanisms to innovate and create new business models. And last, but not least, they are acting as platforms to provide partners and customers to create even bigger value.

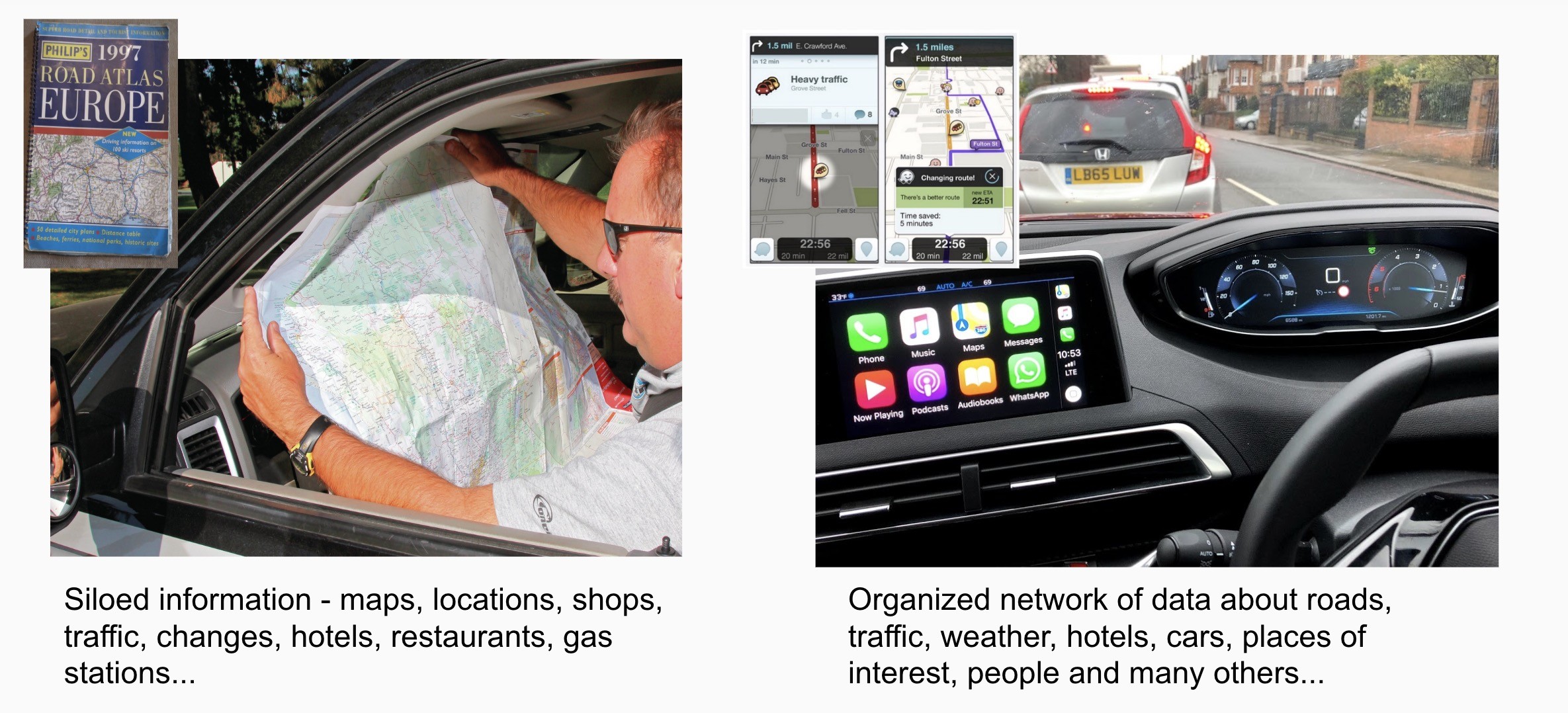

Networks have strong impact on the process of digital transformation. Here is the example of how technologies were gradually changing the driving process over the course of the last 40 years.

Each small step was helping to create new value and provide a new experience. If you look on the process from the perspective of 40 years changes, here is what you get.

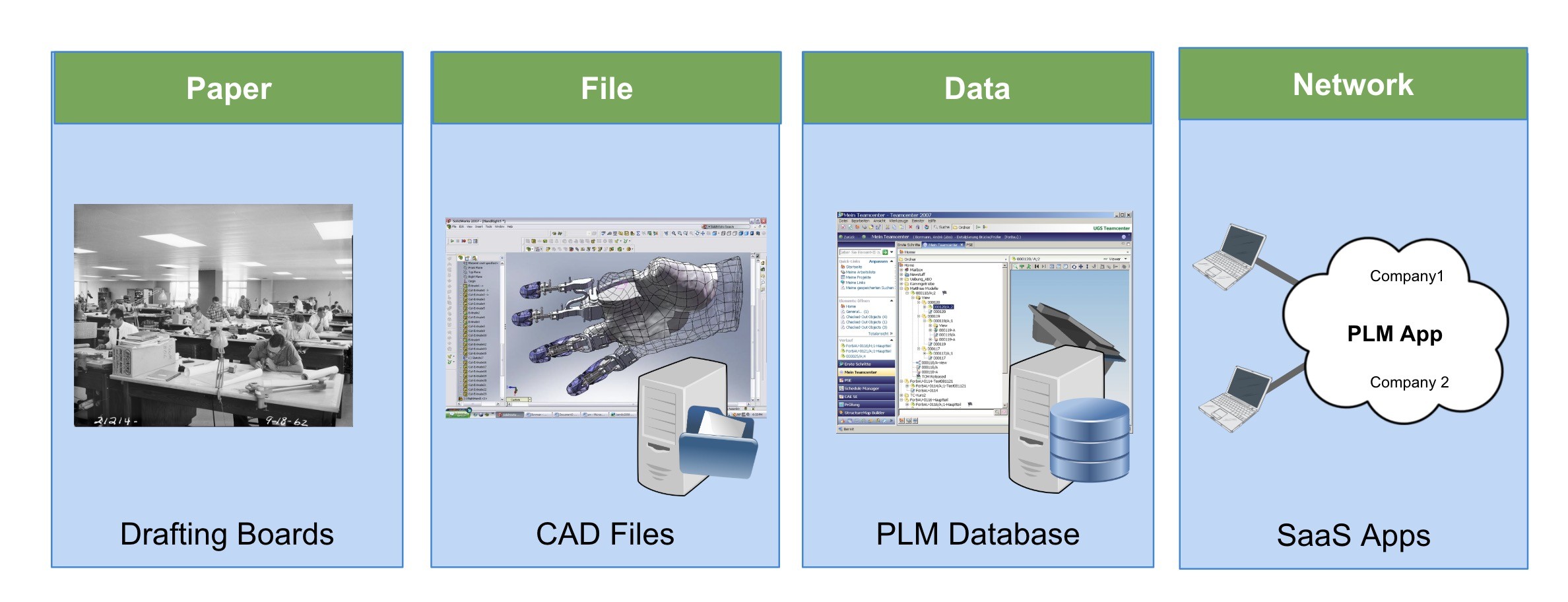

So, what does it mean for manufacturing companies and why it matters? The digital transformation in manufacturing started long time ago when companies started to move from paper and drawing boards to digital technologies. Think about paper and drawings. The first step was to create a computer-based (digital drawing board). The next step was to come from a file to databases. The last 20 years of PDM/PLM development created database systems to manage engineering, product, and lifecycle. This is how far we got in the digital transformation until “a cloud came in”.

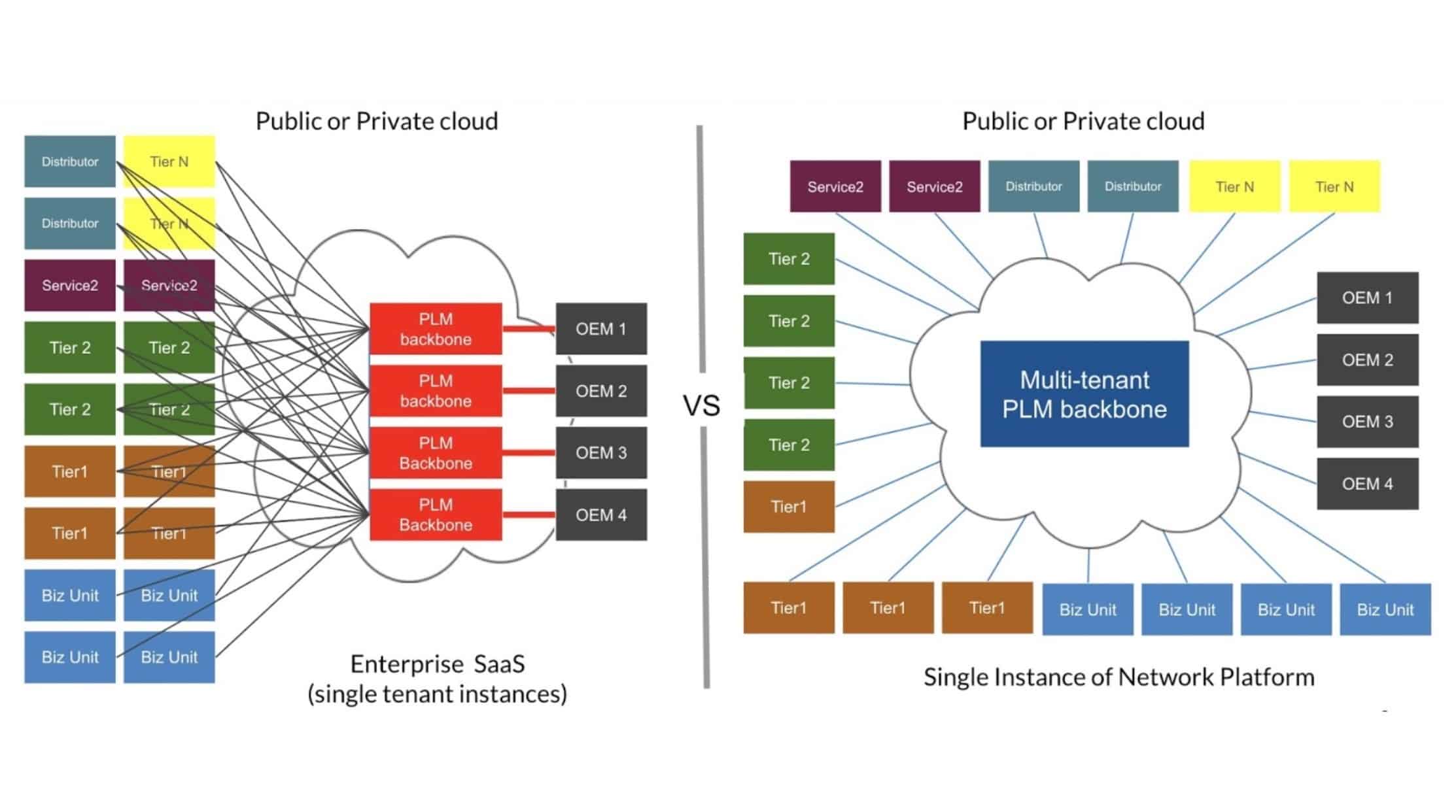

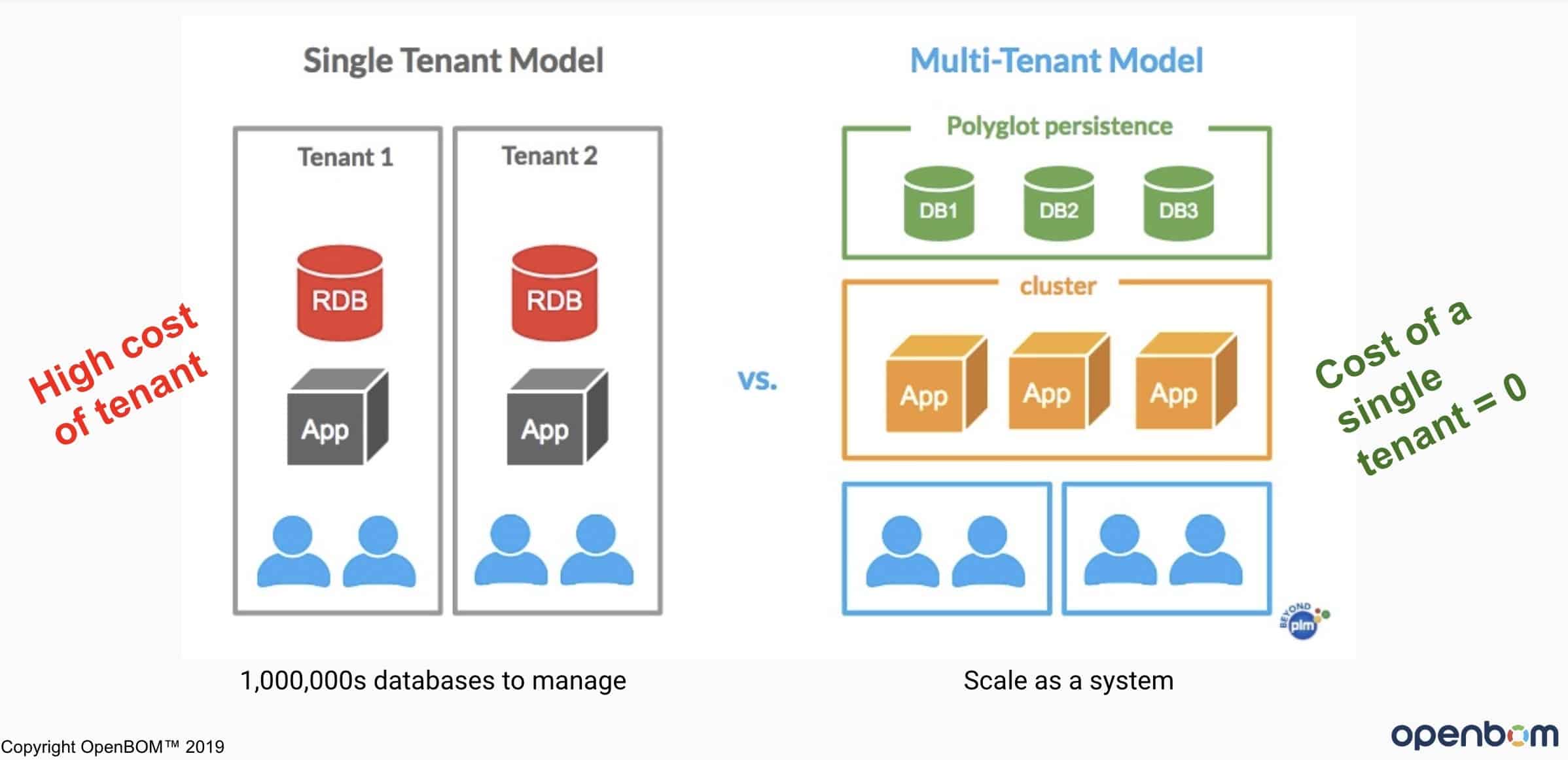

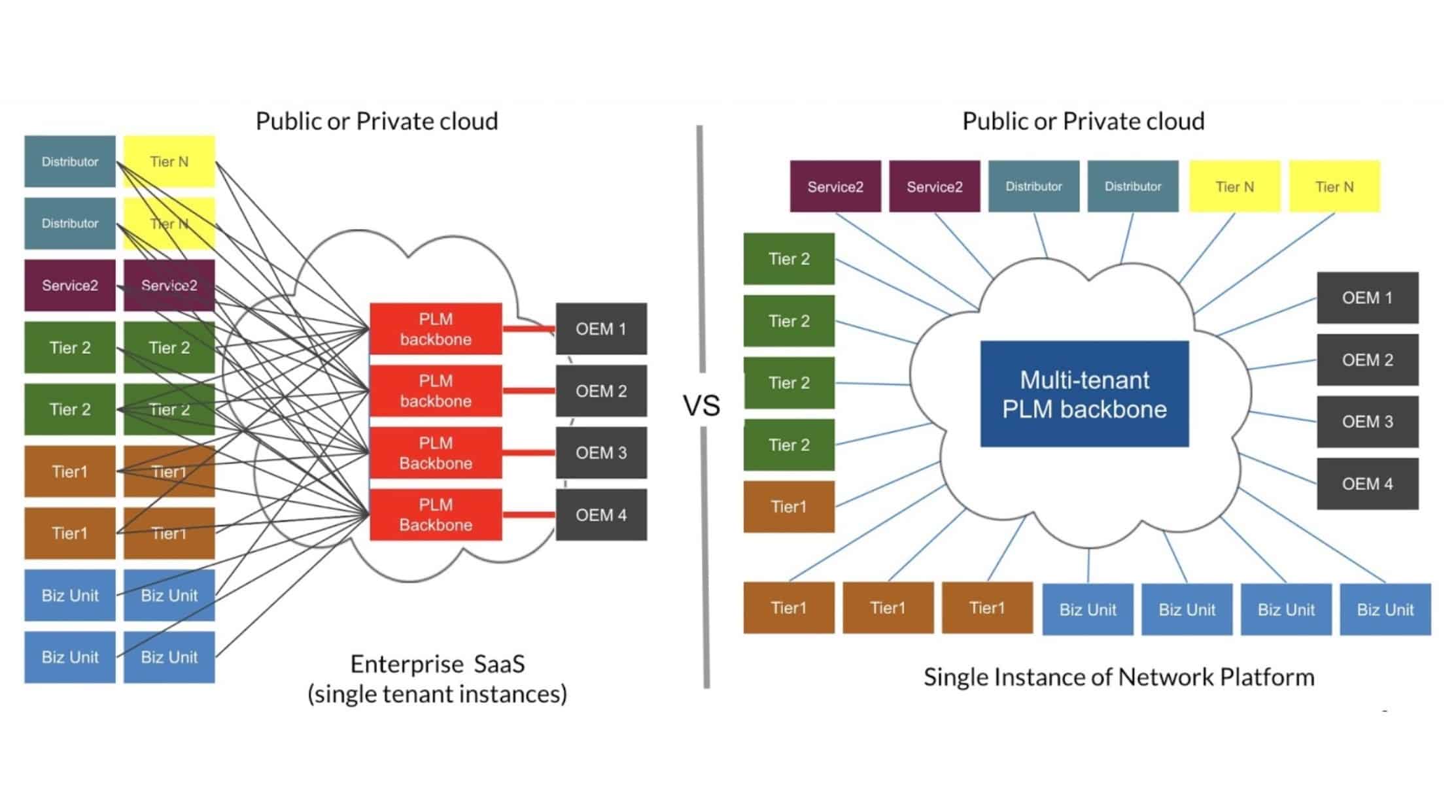

Hosting a PLM database in the cloud has its limitations. And the main one is related to the tenant model. In the following picture, you can see that a single-tenant model is limiting companies to leverage an economy of scale.

And from the standpoint of data and integration, the single-tenant model doesn’t provide any advantages for companies to collaborate and communicate. Companies are still limited to a single database tenant.

Is there a better way? This is what we develop at OpenBOM – multi-tenant data management and collaboration application and technologies to connect companies, data and support innovation, openness and collaboration.

If you want to check my slide deck, the link is here.

Conclusion

The network is a foundation of new data management technologies and collaboration. OpenBOM offers you a unique way to use OpenBOM applications via variety of subscriptions. OpenBOM uses the economy of scale to make these technologies affordable even for smallest engineering prototyping teams as well as for large companies.

Check our website for more information – openbom.com and register for FREE user account – no string attached (including the ability to create and manage BOMs, catalogs and integrate with CAD systems. Register for your account here.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.