In today’s interconnected world, data plays a pivotal role in the functioning of companies across various industries. For manufacturing companies, the shift has been significant, moving from considering data as mere documents that document post-design and manufacturing processes to embracing product data as the central pillar upon which all product development decisions are made. The future belongs to systems capable of managing product data in an open, flexible, and transparent manner, and this vision was highlighted at Autodesk University 2023.

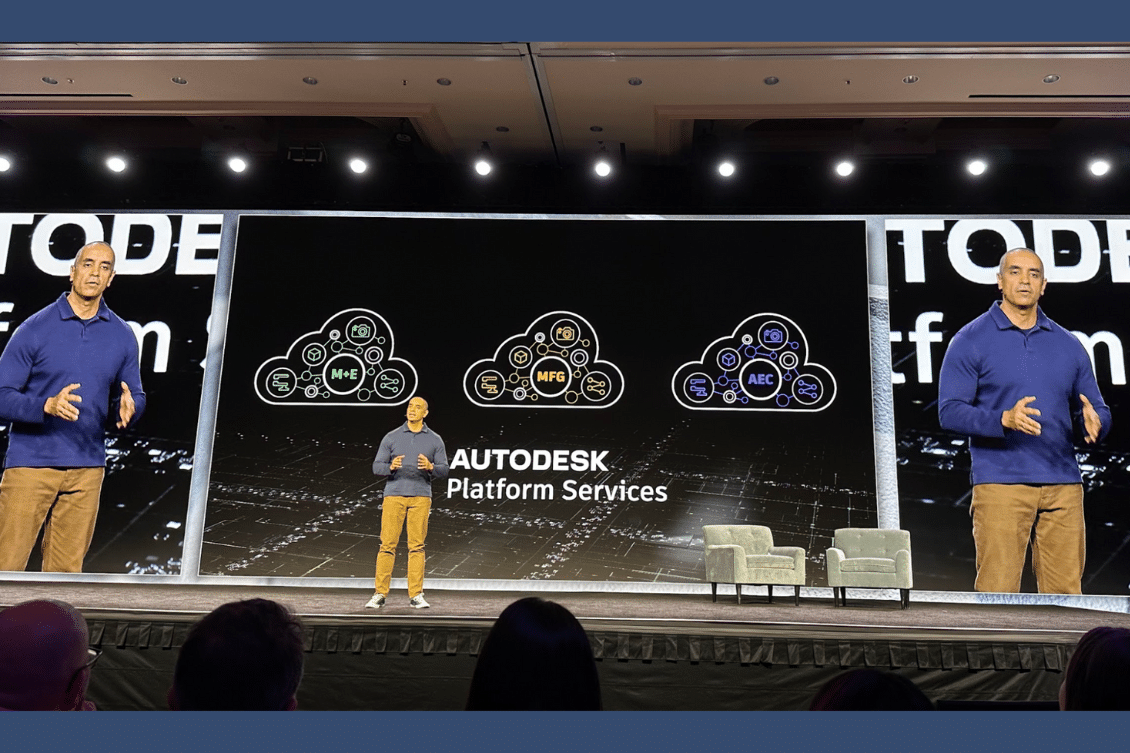

Autodesk Platform Services (APS):

Autodesk, a pioneer in design and engineering software, is taking bold strides in accelerating the development of Autodesk Platform Services (APS), formerly known as “Forge.” APS is poised to become the foundation for managing product data effectively. A crucial part of Autodesk’s strategy is to create reliable and open capabilities for data management and to connect seamlessly with various online APIs to extract and consume data.

APS relay is on the industry-specific data model and open API. APS integrates all design data coming from multiple applications.

It is granular and connects to multiple Autodesk and non-Autodesk solutions .

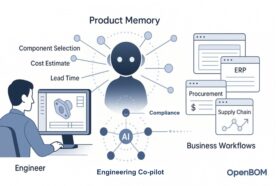

OpenBOM’s Vision:

OpenBOM, on the other hand, is aligned with the vision of creating an online platform capable of managing flexible and robust product data sets while integrating seamlessly with other products and processes.

At the core of OpenBOM lies a robust data model and collaborative components designed to facilitate the integration of multiple systems.

The Synergy between Autodesk (APS) and OpenBOM:

Both APS and OpenBOM share the vision of product data and openness. Therefore we put the topic of seamless connectivity between Autodesk Platform Services and OpenBOM to achieve a better user experience.

Seamless data capture from the design environment.

OpenBOM effectively harnesses various APS data APIs, such as the Manufacturing Data Model API, to continually bridge the gap between design, production, and the supply chain. The result is a harmonious integration that facilitates the smooth flow of data for both manufacturing and construction projects.

The Outcomes of Seamless Integration:

The seamless integration between OpenBOM and Autodesk Platform Services brings forth numerous benefits. First and foremost, it streamlines the exchange of data, reducing the complexity associated with data management and facilitating real-time decision-making. OpenBOM’s ability to federate data enables teams to collaborate effectively and make informed choices throughout the product development lifecycle.

Conclusion:

In the modern era, the ability to seamlessly connect and exchange data is a defining characteristic of cutting-edge cloud services and applications. The days of data transfers via Excel spreadsheets and emails are slowly becoming history. Companies that fail to embrace real-time data communication risk falling behind in the ongoing digital transformation. OpenBOM and Autodesk Platform Services are at the forefront of this revolution, offering innovative solutions to streamline data management and foster collaboration.

To explore the potential of OpenBOM, we invite you to register for a free trial and share your thoughts and experiences with us. For further information about Autodesk Platform Services, please visit [Autodesk Platform Services formerly Forge].

In a world where data is king, OpenBOM and Autodesk Platform Services are leading the charge toward a future where product data reigns supreme, enabling companies to thrive in the digital age.

REGISTER FOR FREE and see how OpenBOM can help you today.

Best Regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.