Have you ever wondered what all those visualization types in OpenBOM are for – Single-level, Multi-level, Flattened? OpenBOM is a powerful PLM and data management tool that provides a robust and wide range of features for users in the manufacturing industry helping them to manage parts, bills of materials, product lifecycle, inventory, vendor, purchases, and many others. However, the core of OpenBOM is a robust product structure data model that allows the management of BOM for the engineering team, a manufacturing company, contract manufacturers, and supply chain.

In this post, we’ll take a look at some of the different types of visualizations that are available in OpenBOM to manage the Bill of Materials. We’ll also discuss how each type can be used to simplify your work to create, share and manage changes in Bill of Materials and related data. So, let’s get started!

Product Structure, not a BOM Excel…

Let’s start by saying what OpenBOM is not. Although OpenBOM looks and feels like Excel, it is not Excel and it is very important to understand once you’re starting to work with Excel. Although, it is very easy to think that BOM = Excel, that would be a fatal mistake that will cost you time and confusion. The core of OpenBOM is a robust product structure model that is using a set of NoSQL and Graph Database to organize and manage information. A combination of databases gives OpenBOM data management flexibility and many other important features we will talk about later.

The foundation of the OpenBOM product structure is an instance-reference data model that is managing two major information objects – Items and Bill of Materials. The first (Item) is controlling all the information about different types of engineering and manufacturing items (eg. Standard Part, Material, Sub-assembly, Product, etc). Anything can be an item, it is identified by a unique Part Number and OpenBOM is allowing to define a flexible set of additional attributes (properties) for each item. Items are managed using Catalogs. Read more about it in OpenBOM Training Library.

The second fundamental object is a BOM (Bill of Materials), which includes a list of components for a specific Item (in case an Item is assembly, of course). If so, BOM has a Part Number and it always includes a list of Items (each item has a part number). In such a way, a BOM includes a list of items with Part Numbers and a set of attributes (OpenBOM properties). Unlike Items, these properties are called instance properties and they are defined for each BOM.

The third element of product structure – hierarchical relationships are managed by creating a graph structure between items based on the part number and all BOMs. So, by creating items and BOMs, you technically create a virtual product structure stored in OpenBOM databases defining relationships between three objects.

Learn more about the OpenBOM data model and product structures here – Understanding of OpenBOM.

BOM Visualization – Single-Level, Multi-Level, Flattened

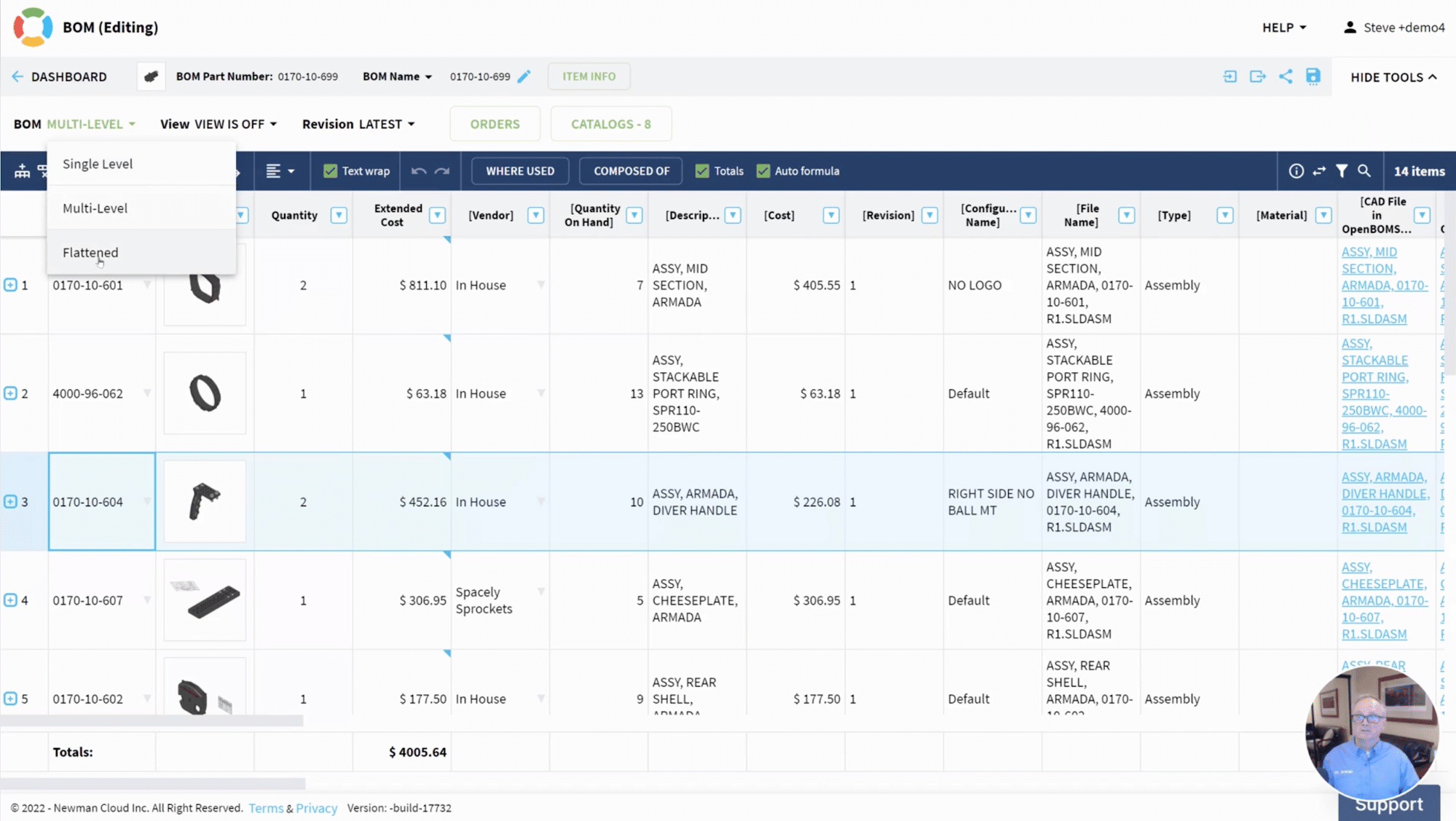

A product structure is a complex structure, but OpenBOM creates a simple visualization model for BOM structure and all objects. As such, OpenBOM provides a flexible data grid that is capable of defining objects with all custom attributes (properties). You can create a catalog with all the information (properties) and edit it in a simple collaborative grid. Bill of Materials can be defined for each item in the catalog and once a Bill of Materials is defined, it produces the list of Item instances with inherited item attributes from catalogs. BOM structure is defined by instance attributes and the most important is Quantity which defines the usage of each item in each BOM. Items and BOMs are organizing a complex information structure that allows any level of complexity.

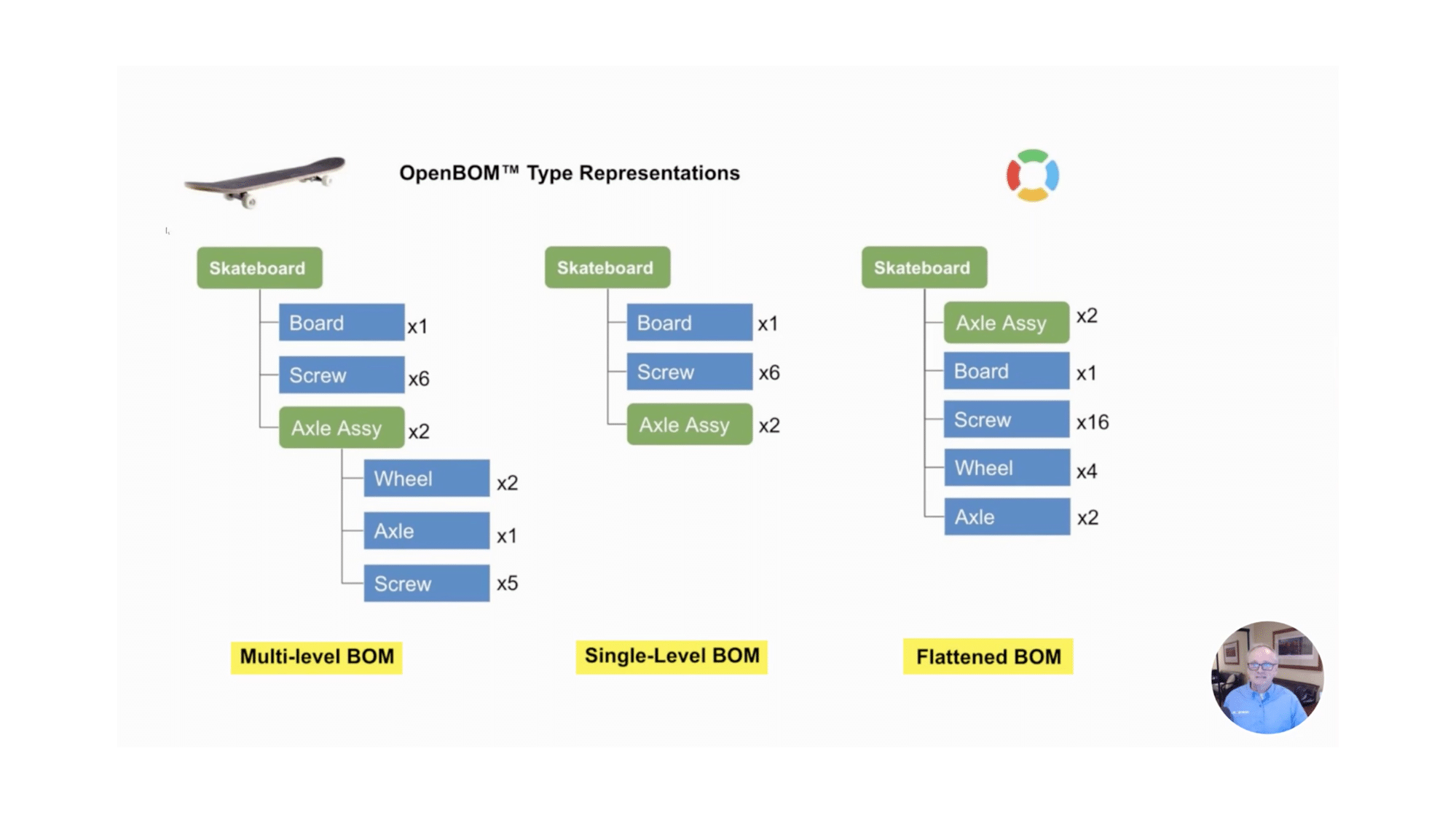

OpenBOM provides 3 types of visualization of BOM structures:

- Single-level BOM

- Multi-level BOM

- Flattened BOM

These visualizations are not different BOMs, but different ways to visualize the product structure and put the information in the collaborative grid. Don’t be confused by thinking that “single-level BOM” is different from “multi-level BOM”. It is just two different ways to visualize the same structure.

Video Demo

In the following video, you can watch an introduction to OpenBOM BOM visualization types and get some best practices on how to use it in practical editing and structure manipulation.

A single-level BOM is the easiest and simplest to edit. Editing a single-level BOM simplifies what you do because you edit a simple list (a slice) in a complex product structure. Use it when you need to define a specific level in your product structure.

A multi-level BOM is the most comprehensive structure in which OpenBOM allows you to drill down in all structure elements (items) as well as allows you to edit the structure by applying a variety of operations to “down, up, shift left and shift right”.

A flattened BOM is the most interesting visualization type, which gives you a way to summarize a structure in a flat list by roll-up of item quantities across multiple levels.

Conclusion

Although OpenBOM might look like a simple Excel spreadsheet it is a mistake to think about OpenBOM as a better way to store your Excel in the cloud. OpenBOM is a comprehensive data management service allowing you to manage complex product structures and share information with your team, contract manufacturers, and suppliers.

Want to experience OpenBOM product structure and BOM editing? REGISTER FOR FREE and start a trial to use OpenBOM for 14-days.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.