Capturing data from CAD design and the creation of the Bill of Materials is a complex process. At OpenBOM, we want to simplify the process. Our CAD integrations are the way to do it in a very simple and streamlined way. If you are not familiar with OpenBOM CAD integrations, check out our training library online – Import Data from CAD.

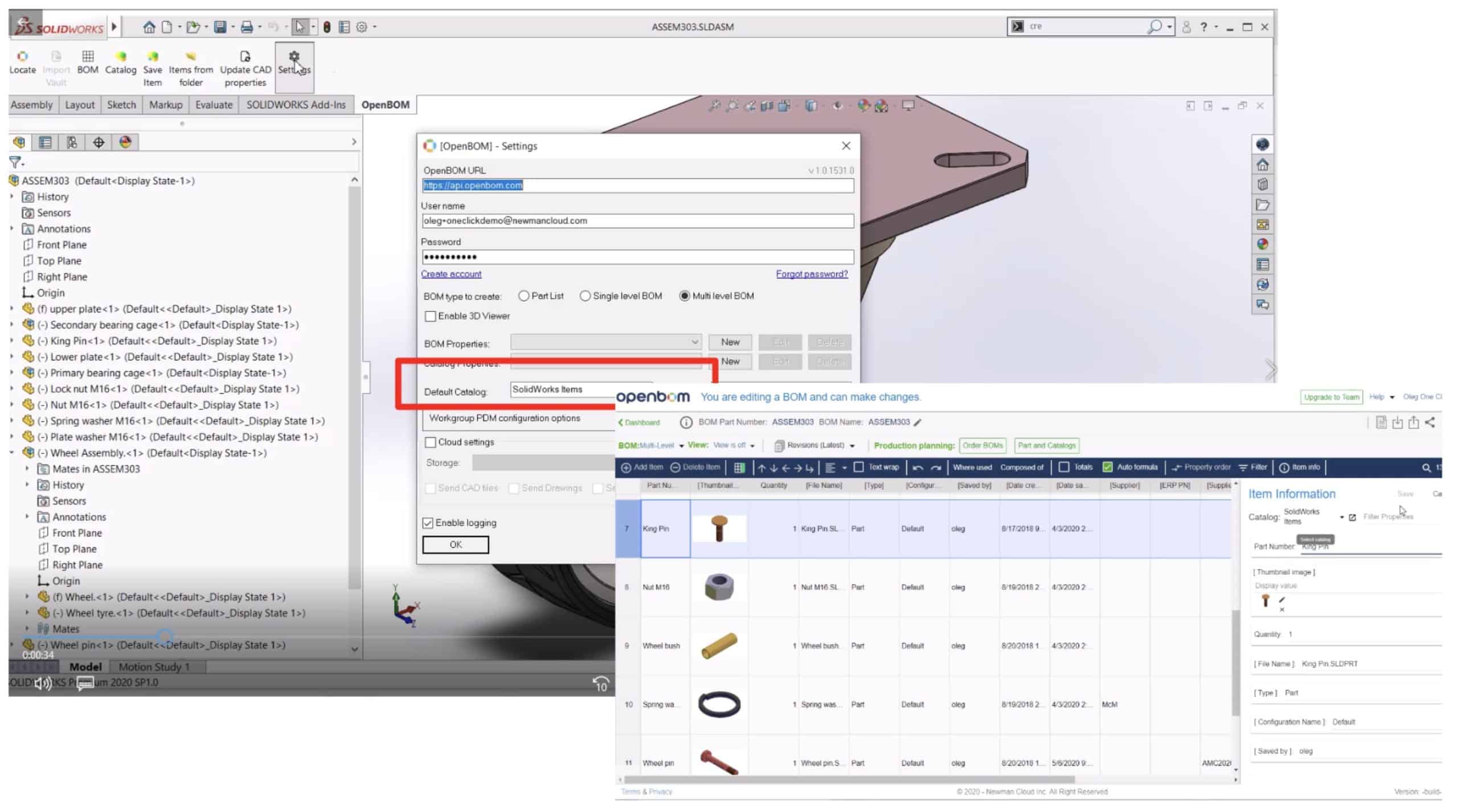

We are always looking at how to simplify CAD data extraction even more. In my blog today, I want to talk about recent improvements in OpenbOM CAD integrations called “One-Click”. This feature is the next step in simplifying the process of the Bill of Materials creation and data capture from CAD systems by OpenBOM. It combines the ability of OpenBOM simultaneously to create a Bill of Materials and to save items in the catalog. To control the process of catalog creations, we introduced Default Catalog settings. It will allow us to save item information directly from Solidworks to the default catalog. Bill of Materials creation process is now technically a single click on the “BOM” button.

Now, you can seamlessly share and collaborate data using an online engineering bill of materials from initial design through all steps of manufacturing and supply chain. You can develop service specifications that comply with cust demands and services ability. Everything is available for your convenience.

Check this video for the demo of the one-click and default catalog. You will see how easy now to create multiple bills of materials and accumulate information about all items in a single catalog.

Managing a single catalog (default catalog) is the simplest way to start working with OpenBOM and CAD integrations. But it doesn’t mean you cannot make it more sophisticated and to use multiple catalogs. Below I put a few options on how you can organize data in OpenBOM using one-click and catalog configuration.

Option 1: Default Catalog

The simplest way to manage data. All items from CAD (eg. Solidworks) will be saved in Solidworks items catalog or another default catalog – you just need to put your own name there.

Option 2: Generate catalogs based on assembly or folders

Before the creation of the Bill of Materials, use Catalog command or Items from Folders command. The data will be saved in the catalog(s) and you will be able to connect these catalogs later to the BOM. When creating BOM, only items that NOT saved previously in the catalogs will be saved in default catalogs.

Option 3: Saving Items to a specific catalog

Another option “Save Item” allows you to save information about a specific item (Solidworks part of assembly) in the catalog of your choice. The selection of the catalog will be done for each Item.

Conclusion

The new “One-Click” feature combined with default catalog settings is the next step to simplify the process of data collection in OpenBOM from CAD designs. It can be used to streamline the process of BOM creation basically stripping it down to one click. Combined with existing features of Save Item, Items from Folder(s), and Catalog from Assemblies, the new Solidworks add-in is the next level of robustness in BOM creation.

If you already have Solidworks add-in installed, don’t forget to click on the “Update” button to install the newest OpenBOM Add-in and try new features immediately.

Check our how OpenBOM helps thousands of users and manufacturing companies to streamline data management, processes, and escape the legacy of Excel spreadsheets.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.