The foundation of every digital product development and manufacturing organization is an information system that is capable of managing data and orchestrating a seamless and efficient data handover process. As manufacturing companies move towards digital transformation, the question of what infrastructure and systems can support the most efficient and seamless data workflow is on the top of the mind of every engineering IT manager.

Digital Workflow

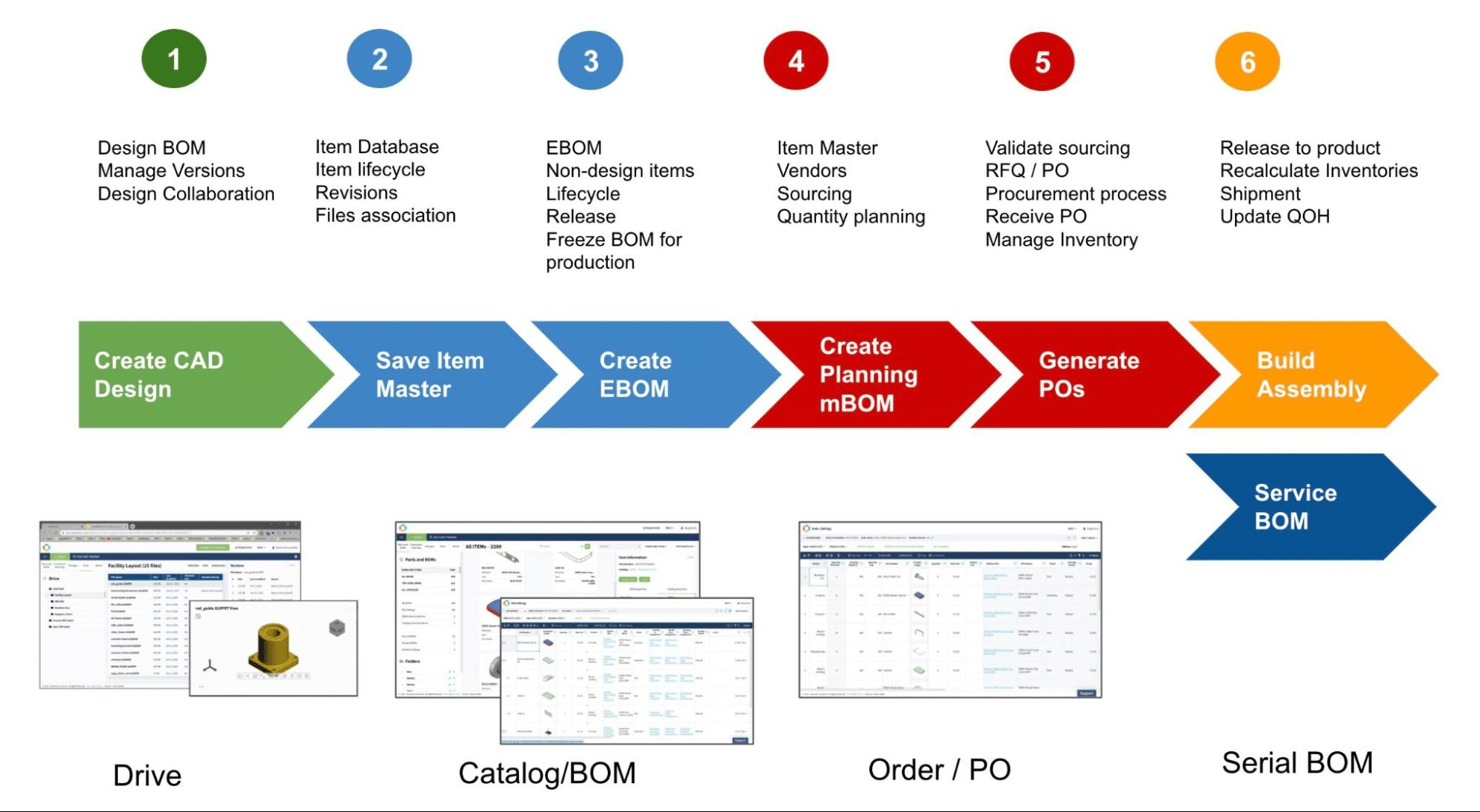

At OpenBOM we put a special emphasis on how people and systems can interplay together by helping to support seamless data handover. It includes, but is not limited to management of files, items, bills of materials, and then downstream to production, purchasing, and maintenance. In the picture below you can see OpenBOM services that are supporting this seamless information workflow.

CAD Integrations and BOM Process

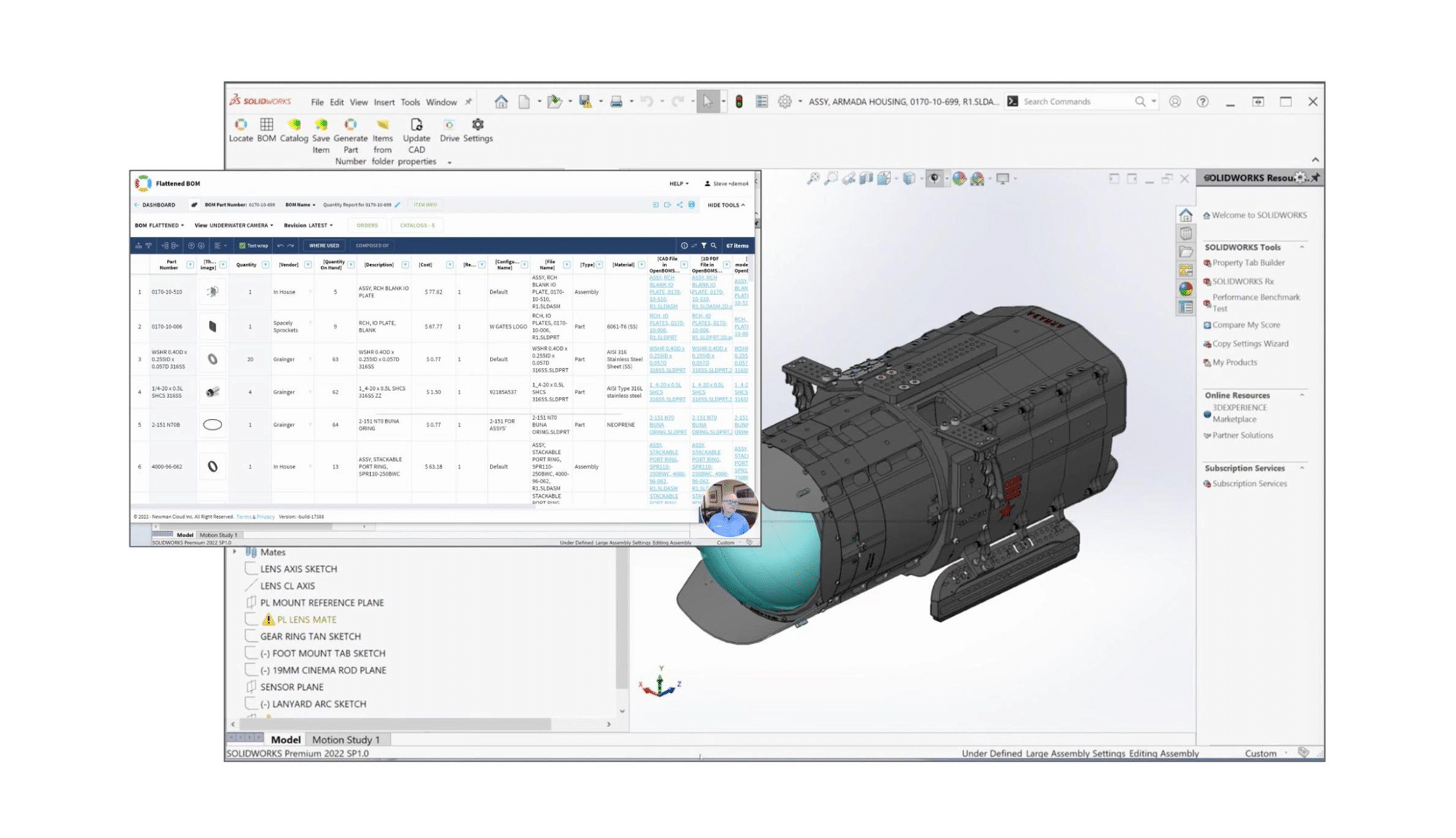

The foundation of the BOM process in OpenBOM includes a set of tools and services that helps manage Items and Bill of Materials and integrate information coming from design in a variety of ways to create a multidisciplinary Bill of Materials.

The inflow of information can come in a variety of forms – manually created, imported via spreadsheets (Excel, Google Spreadsheets), or imported from CAD systems using OpenBOM CAD integrations.

In the following video, we present how information can be captured from CAD design using OpenBOM for Solidworks and how the data can be seamlessly integrated and connected between design and engineering.

Watch the video to learn more about it.

Conclusion

A foundation of every digital organization is an information system(s) capable of organizing a seamless information flow and data handover process between systems and people in an organization. Any product development and manufacturing organization is built around the process of design, engineering planning, production and procurement planning, and maintenance. In my view and story today, we demonstrated how OpenBOM can help any engineering team and manufacturing organization handle data management and product development processes by creating an efficient design for the engineering BOM (EBOM) process. It includes efficient capturing of information, seamless integration, and automatic data transfer.

REGISTER FOR FREE and start a 14 day trial to check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.