Every manufacturing organization these days needs data and data management. The time when the most updated BOM was on the corkboard and any person on the shop floor knew that they need to order some fasteners (because they always do) is over. Modern manufacturing companies demand sophisticated data management to integrate data, manage engineering and manufacturing processes, coordinate their supply chain and bring their data silos together. This is a reality. You cannot be serious and believe that you can manage all data objects – bill of materials, engineering and manufacturing BOMs, inventory, and procurement planning using Excel or Google spreadsheet.

From Networks To Global BOM Graph

Graphs are taking a central place in modern data management for engineering and manufacturing. The nature of BOMs is very graph-like (check my BOMs and Graphs Part 1; Part 2 and Part 3) and the trajectory is to bring Graphs in BOM and Product Structure management is getting stronger every day. Although the Bill of Materials and product structure is usually presented in hierarchical ways, in fact, when it comes to multiple products, assemblies, and components, the data in product structures creates a complex structure that can be very efficiently managed as a graph structure.

The novelty of the graph approach in product lifecycle management and BOM management allows building a new type of applications, especially for data analytics and data intelligence. Using graph data representation, the theory of graphs, and network maths, modern cloud data management systems can glean intelligence and information that cannot be obtained from Excels and old legacy databases. In my earlier article – Graph Centered applications, I discussed different types of applications and business use cases around them that can be applied for product development and manufacturing companies.

Modern multi-tenant data management architecture brings another perspective in the PLM – Global BOM graph. The key differentiator of this approach is the ability of modern data management platforms to build a data structure in a multi-tenant data model capable to coordinate multiple companies, supply chain networks, and global industrial companies.

Why does your OpenBOM catalog need to be powered by a knowledge graph?

I’ve said it before, and I’ll say it again — the key elements of the OpenBOM data model is catalog systems, which is a distributed database holding multiple catalogs representing items and corresponding information in the way of multiple properties. In such a way you’re getting a set of catalogs to manage products, standard components, mechanical and electronic hardware, software code binaries, and many other elements. The catalog system is fully flexible data objects holding all the information.

Your company data management is as strong as a system of catalogs you will be building in OpenBOM. Through the system of catalogs, everyone involved in product design, engineering, and manufacturing processes will get information about a product, its lifecycle state, purchase order management, and many other parameters.

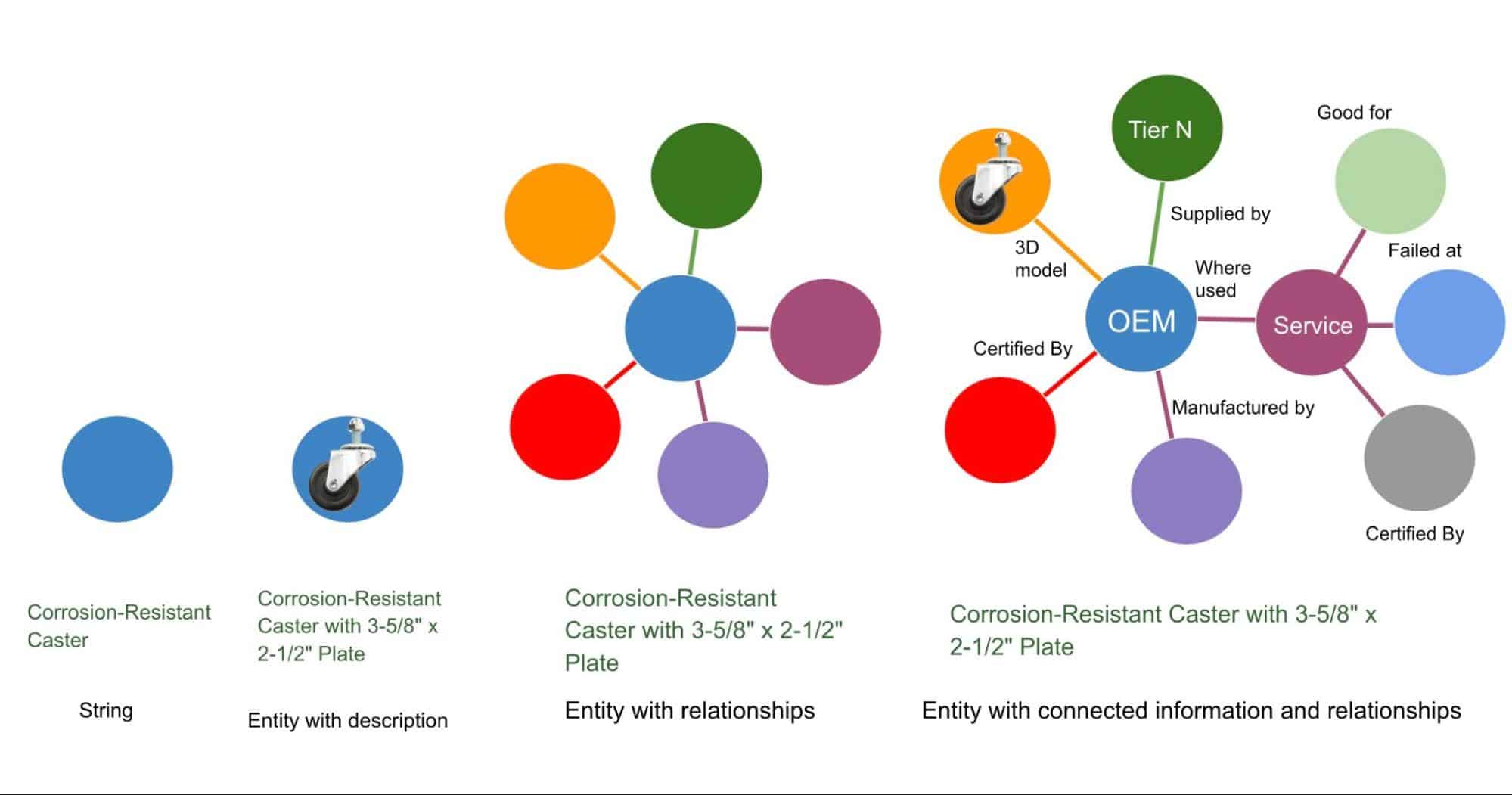

Here is the important element thing – the data management architecture goes much beyond tables these days. OpenBOM catalogs help engineers and everyone else in the company to get a better data insight to an entire data set and you can do it via the system called “knowledge graph”. A knowledge graph consists of nodes and edges representing data objects and the relationships between them. These elements of the graph can represent multiple data objects – parts, BOM, orders, revisions, cost, suppliers, etc. The edges (in the graph) represent the relationships between objects and how they’re associated, connected, derived from, etc.

There is a big difference between legacy data management architecture and modern data stacks. The knowledge graph is a metadata layer on top of the existing data management architecture enabling a special type of relationships and understanding of the data. The global nature of the data, connectivity between multiple subjects, and relationships allows you to build a semantically rich data management model capable of capturing information from engineering and manufacturing processes, represents the semantic similarity between data, and scale the data platform into a global data management platform.

Knowledge data architecture is a foundation of data management platforms such as Airbnb, Lyft, LinkedIn, and some other companies. All these companies have built their platform using knowledge graph technology.

OpenBOM Graph Enabling Platform

The foundation of OpenBOM is a polyglot persistence data management architecture using multiple databases to optimize data and to provide a scalable and semantically rich platform for engineers and manufacturing companies need to manage their data assets.

Specifically for knowledge graph representation, OpenBOM is using a Neo4J database platform capable of managing information relationships on a global scale, connecting pieces of information between multiple items, BOMs, vendors, purchases, and orders.

In the coming months, we will start the process of creating a Graph Aware Application that will be leveraging data structures managed by graph systems. We are planning to start with visualization applications capable to show the complexity of data relationships between multiple companies and supply chain networks. More information will be coming soon.

Conclusion

OpenBOM platform is purposely built on top of a modern data management stack including multiple databases and uses a graph database to empower data management, semantic relationships, and a variety of capabilities of graph analytics to provide data insight and data-driven decision-making support.

OpenBOM is continuously developing and improving graph technologies and the implementation of knowledge graphs to support the global manufacturing product development lifecycle.

Check out what OpenBOM can do for you – REGISTER FOR FREE and start a 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.