OpenBOM is a cloud-based software designed for managing product information including bill of materials (BOM) across the entire product lifecycle. With OpenBOM, teams can collaborate on design and engineering changes, track inventory, and plan manufacturing processes. One of the essential features of OpenBOM is the change management functionality, which allows users to track revisions and modifications made to a product.

In yesterday’s article, I presented three fundamental mechanisms to support the change management processes in OpenBOM – Revision, Change Request, and Change Order. In this article, we will focus on the first one – revisions. I’m going to explain how OpenBOM can help you to manage Item and BOM revisions.

Items and Revisions

The fundamentals of data management in OpenBOM are creating Items and BOMs. If you want to learn more about OpenBOM catalogs read this article – Organizing Items in Catalogs. Once you have items organized in catalogs, you have a basic record of anything – standard parts, assemblies, materials, etc.

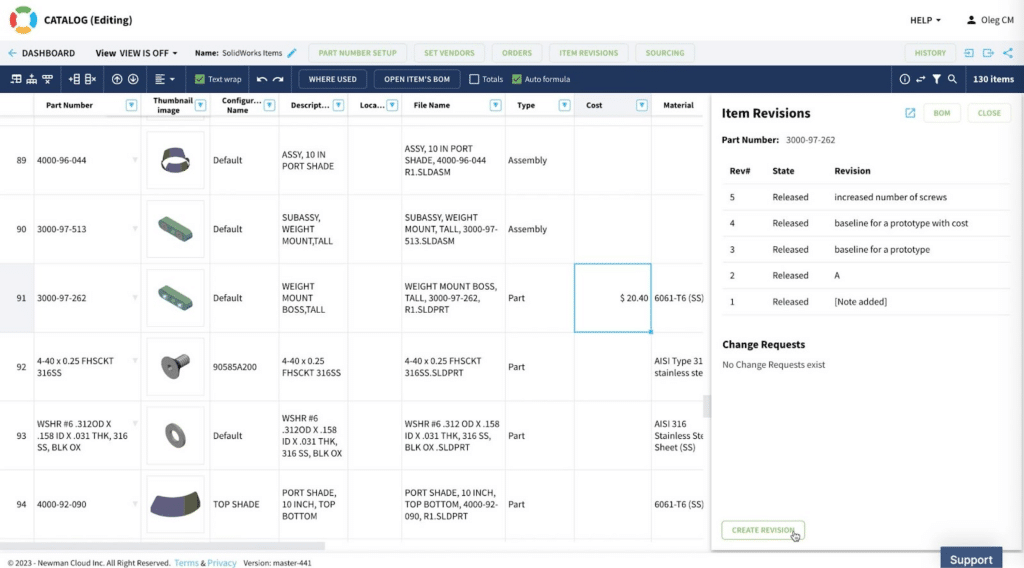

In my example below you can see the OpenBOM catalog with item records. The revision function allows you to see all revisions of a selected item as well as create a new revision. A revision is a record that represents a snapshot (immutable copy) of the item data.

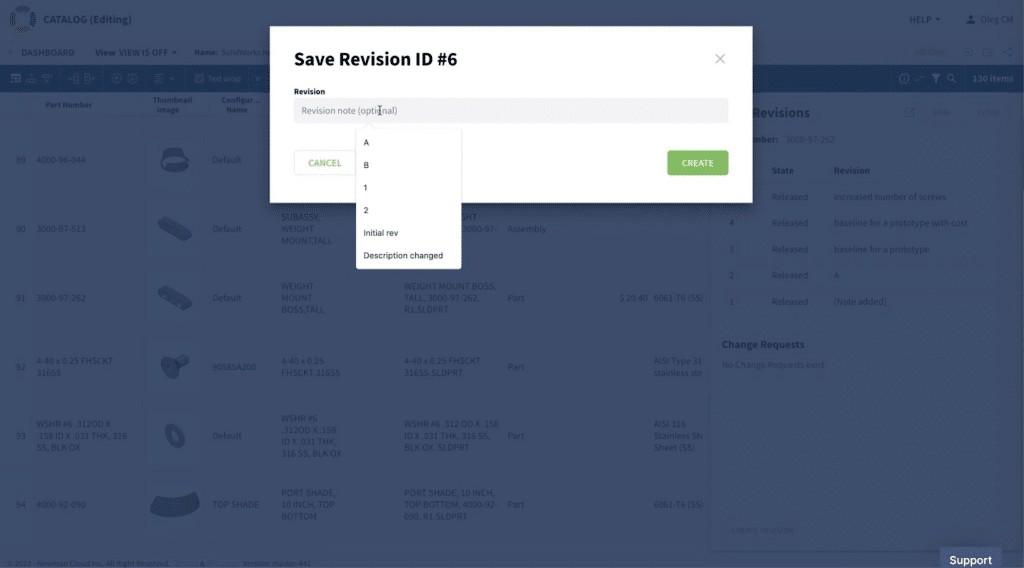

You can edit data freely in the catalog, but once you reach the point when you need to create a revision record, you just use the “Create Revision” command, which will do a new record (revision).

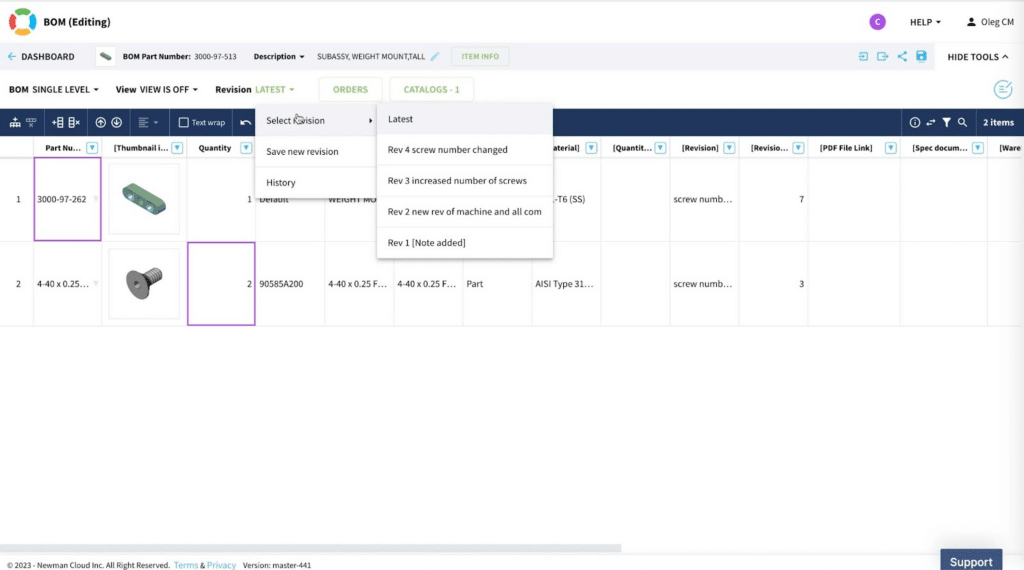

Once you have it saved, you can get access to all revisions stored in the history.

Items, BOMs, and Revisions

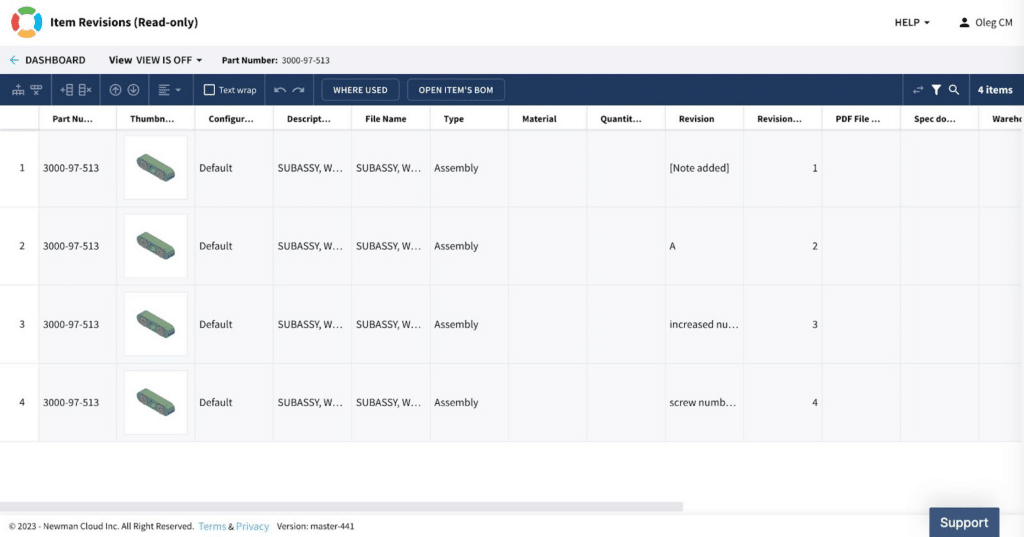

Now, since we learned about simple items and revisions, let’s discuss what can happy when you have an item that is an assembly or, in other words, it has a BOM. A BOM is a list of other items used by the assembly to build it.

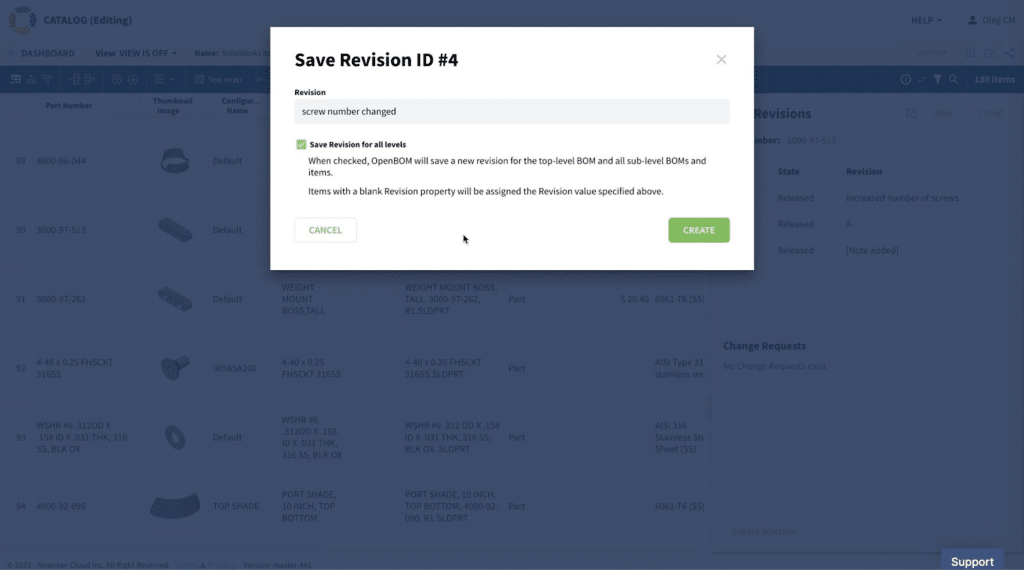

Once you want to create a revision for an item that has a BOM, the prompt will be different and OpenBOM will ask you if you also want to create a revision for all items in the assembly. We will talk about the pros and cons of this choice in a separate article. At this point, we will check [x] and create revisions for sub-items.

As a result, you will get a BOM where all items will be revisions (new revision will be created) and the revision will be also created for an assembly item itself. See the picture below.

Video Demonstration

In the video below, you can see a demo of the revision process.

Conclusion

Managing product revisions can be a complicated process, especially for organizations that rely on spreadsheets and manual data entry. OpenBOM simplifies the process by providing a single source of truth for all product data and revisions. The change management demo allows users to create and track revisions, compare versions, and approve or reject changes.

OpenBOM’s change management demo is an essential tool for organizations looking to streamline their product revision processes. With its user-friendly interface, robust tracking capabilities, and comprehensive audit trail, OpenBOM makes it easy to manage revisions and ensure that all team members are working from the same version of a product. Whether you are a small business or a large enterprise, OpenBOM can help you manage your product data efficiently and effectively.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.