Product structures and bill of materials are complex data entities. A typical BOM is a collection of items that might look like a simple list. But when you attempt to manage data around the Bill of Materials and product structure you can find it insanely complex.

Any product is a hierarchy of elements. These elements can be physical components, logical systems, functions, materials, configurable products or SKUs your company is selling. Depending on how to manage this data, to coordinate and to manage the structure of relationships can be a piece of hard work.

OpenBOM has a sophisticated data management mechanism to control data about the product you design and manufacture. Check more about it here – OpenBOM Data Management Fundamentals. As part of this data management system, OpenBOM is managing reference-instance relationships and parent-child relationships. How we do that?

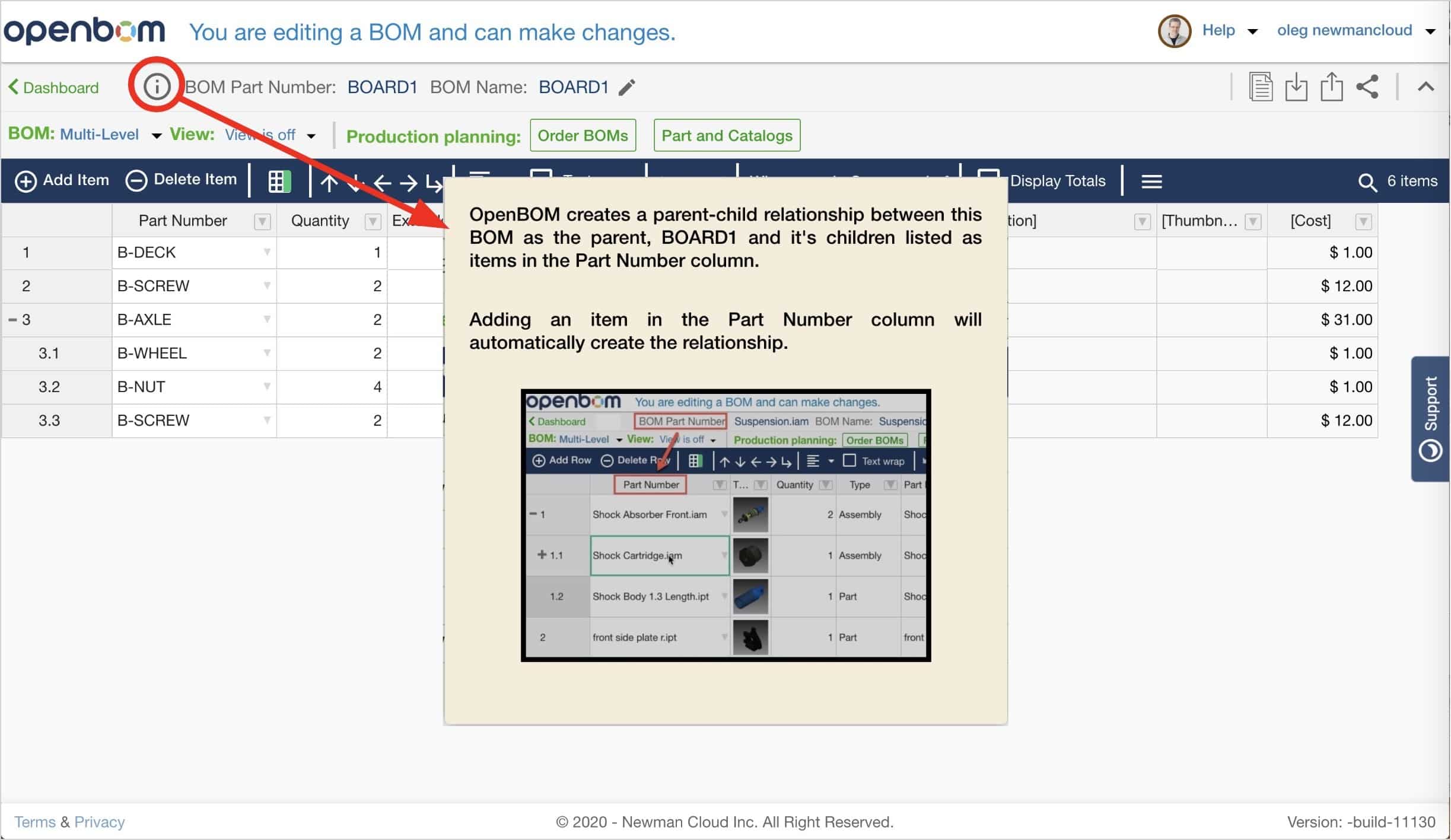

OpenBOM is providing you an on-demand service to manage a structure (parent-child relationships). It means that at any moment of the time when you create items with Part Numbers and Bill of Materials, OpenBOM is establishing parent-child relationships automatically.

The main criteria to establish these relationships is Part Number. We do connect Part Number based on their appearance in the BOM. This means to establish Parent-Child relationships you don’t need to do much – just Add an Item to BOM and type Part Number in the list of items.

This automatic feature is beautiful because it allows you to create this relationship on demand and turn your product structure around by adding specific sub-levels, BOMs created by separate teams, cross-disciplinary elements of the structure (electronics, software, systems) and many others. The benefit is that you can easily construct any BOM, turn it into Flattened, calculate quantity rollup and perform production and purchasing planning.

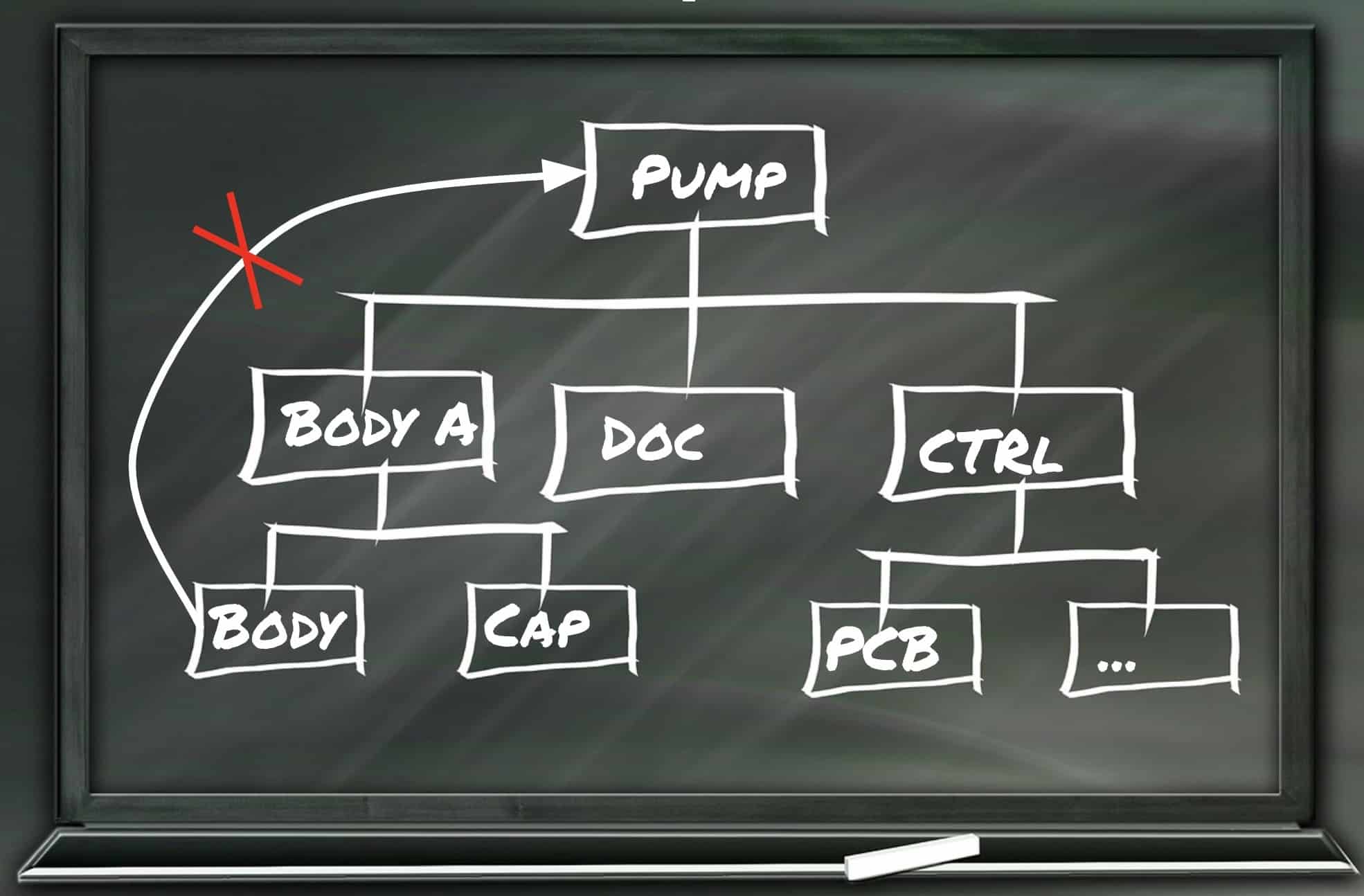

However, it also can easily allow you to make a mistake and create a loop. To explain it simply – it means you assembly “A” has a sub-assembly “SA” and then again includes “A”. Which creates what we call “circular dependencies”.

What are typical reasons you can get such a message:

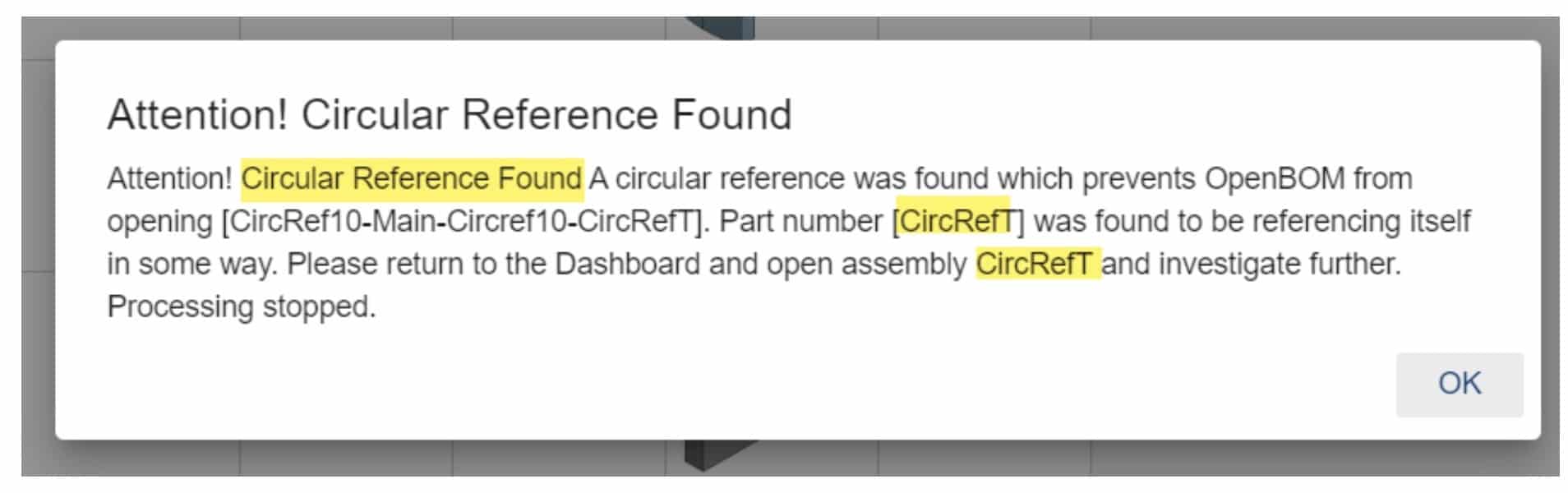

1- Error or Typo in Part Number. As a result, you can get OpenBOM to create circular dependencies.

2- Non-unique part numbers coming from CAD systems. OpenBOM is using Part Numbers to create a product structure hierarchy from CAD systems using CAD add-ins. There are situations when Part Numbers are set not accurately or File Names used as Part Number defaults. In both cases, you will have a circular dependency created.

In the recent OpenBOM release, we improved the way OpenBOM informs you about circular dependencies. This is an example of such a message:

Conclusion.

OpenBOM provides an easy and flexible way to create a product structure. The mechanism is flexible allows you to capture product structure and data hierarchy in many product developments, manufacturing and product maintenance scenarios.

To prevent mistakes and guarantee, product structure is correct, OpenBOM is checking it for circular dependencies and gives you alerts when data must be fixed.

Check out how OpenBOM can be used to create product structure, indented Bill of Materials and other engineering and manufacturing hierarchical relationships.

Check out how OpenBOM can help you to do so. Register for OpenBOM user subscription later today

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Product Lifecycle System and Management can help you cut down on the time associated with building physical prototypes and do much more. If you want to learn more, get in touch with OpenBOM or check the links to get full information. Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.