Few things in life are as frustrating as dealing with outdated and disorganized information. Maybe you’ve experienced this firsthand when trying to track down a specific product part number or price. If so, you’ll be happy to know there’s a better way. OpenBOM is an online data management software that replaces the need for messy excels scattered throughout your company. With OpenBOM, you can easily manage and share your product data with everyone involved in the manufacturing process. Plus, OpenBOM integrates with popular design software like Solidworks and Autodesk Fusion 360, and others, so you can create and edit products right within the system. Check it out today and say goodbye to frustrating Product Excels!

Don’t Trust Excel With Your Product Data

The history of engineering, manufacturing, and other business software such as PDM, PLM, and ERP is full of Excelware. Working with many customers for the last 20 years, I always knew that any manufacturing company even if they use some of the software I mentioned above, always has some “excels” hidden aside that they use (because X software just cannot do what we need). This is happening with large OEMs and enterprises. The situation is awful with small and medium-sized companies. Excel is the second-best software for everything and engineers, production planners, procurement personnel are using them to get things done because other things are just way too expensive, way too complex, and just not flexible to do what they need.

So, how does OpenBOM solve the problem? We built a platform that gives you the flexibility and user experience of spreadsheets combined with sophisticated data and lifecycle management capabilities needed to manage product information such as product structure (BOMs), Item Master, Revisions, Changes, and Files. Let’s talk more in-depth about how it works and what it includes.

3 Elements of OpenBOM Data Model

OpenBOM data model has three fundamental mechanisms – item/instance; product structure; revision and changes. All together they create a unique set of features that allows you to manage product information in the way you need. Let’s talk about each of them.

Item-Instance Model

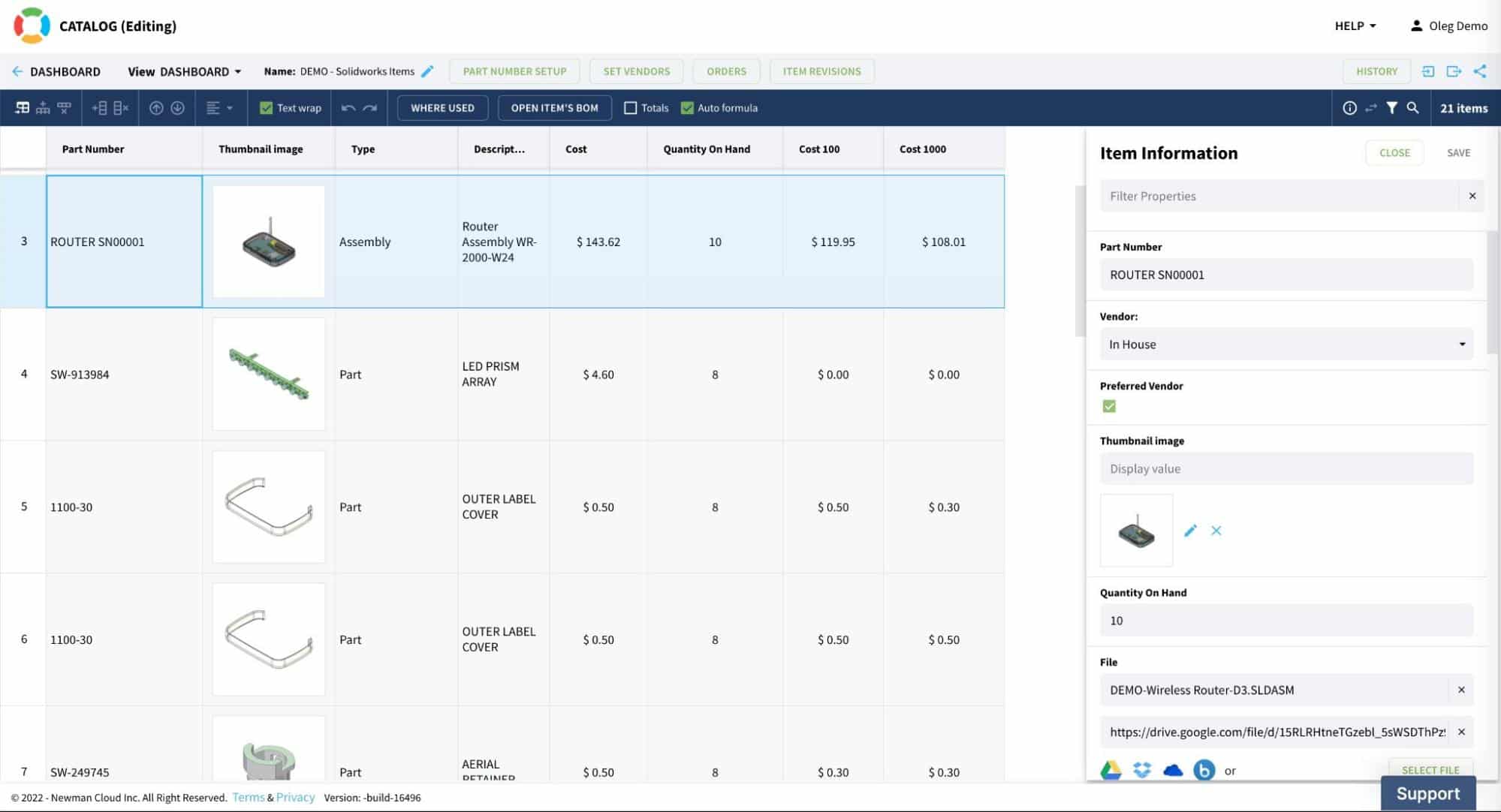

Items are managed using OpenBOM catalogs – distributed databases allowing to manage all items, save them in multiple catalogs and add any attributed (properties) based on each catalog. This is a universal way to create sets of information and to create a single source of truth about items. Once you do that, you can use the items in BOMs (product structure). The information you added to the item is automatically inherited by an item instance and this is how you ensure, the single source of information. To do it in Excel, you need to copy the files and records, which leads to duplication (you don’t want it).

Product Structure (BOM), Flattened, Rollups

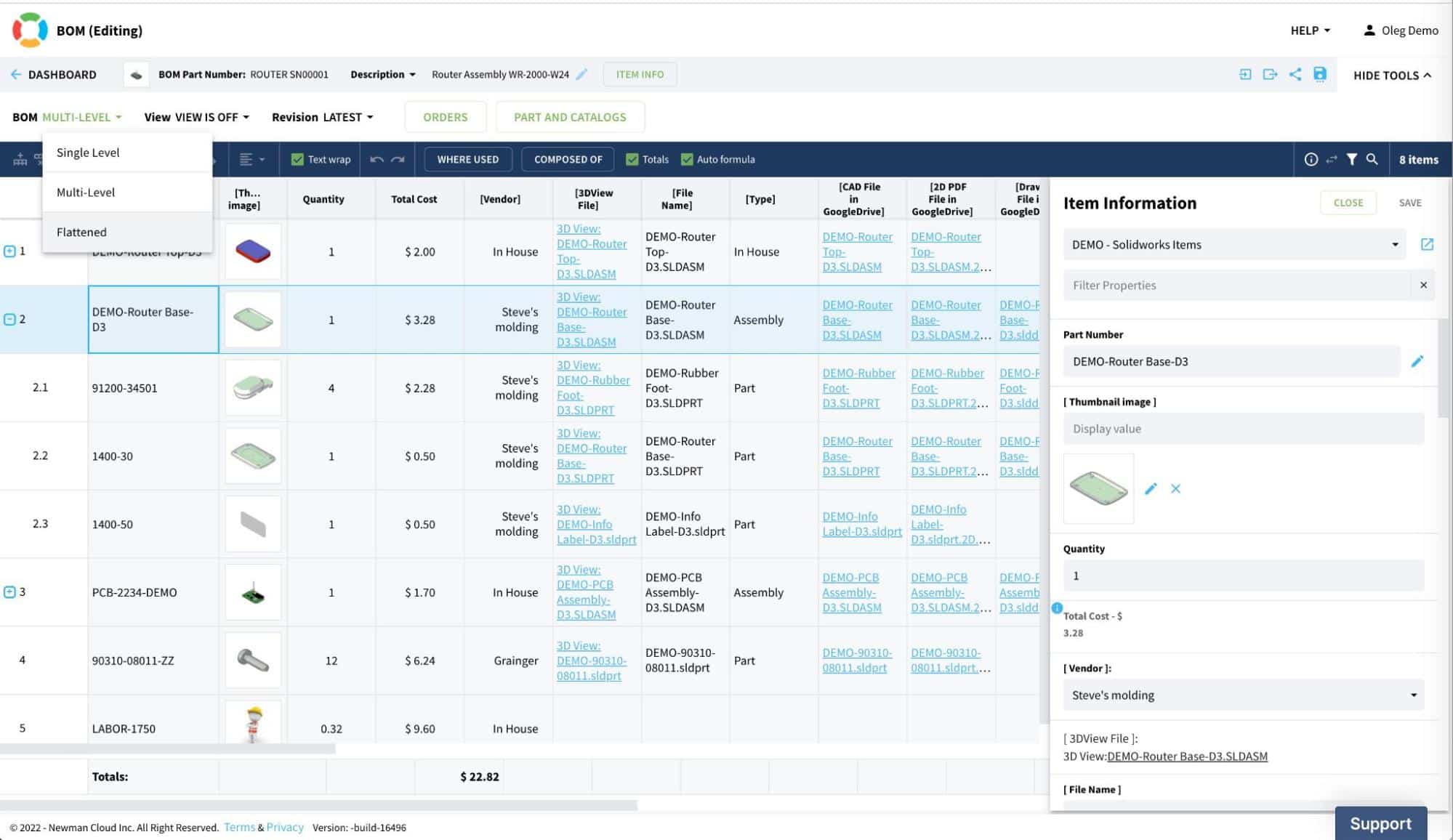

OpenBOM allows you to create BOMs for each item and by doing so, you can build a structure of BOMs – automatically connected using part numbers. It allows you to create an infinite depth structure of elements. BOM records (item instance) are fully flexible and you can add any properties (attributes) to this record. The obvious outcome allows you to store data specifically for item records. The best example is Quantity, which can be different from each instance of the same item. BOM structure is virtual and can be turned between Single level, Multi-level and Flattened. You can work on each of them and edit the data. The most powerful is flattened structure, which allows you to edit a flat structure but apply it multiple times instances at the same time. BOM structure allows you to perform rollup calculations between levels.

History, Revisions, Change Management

Change is the only constant thing in product development. Managing changes is hard and doing it in Excel is prone to many mistakes. Starting from searching for “the last Excel” file and ending with the question of who did what and when. The last thing you want to do is to manage the history of changes, revisions, and change approvals in Excel and emails.

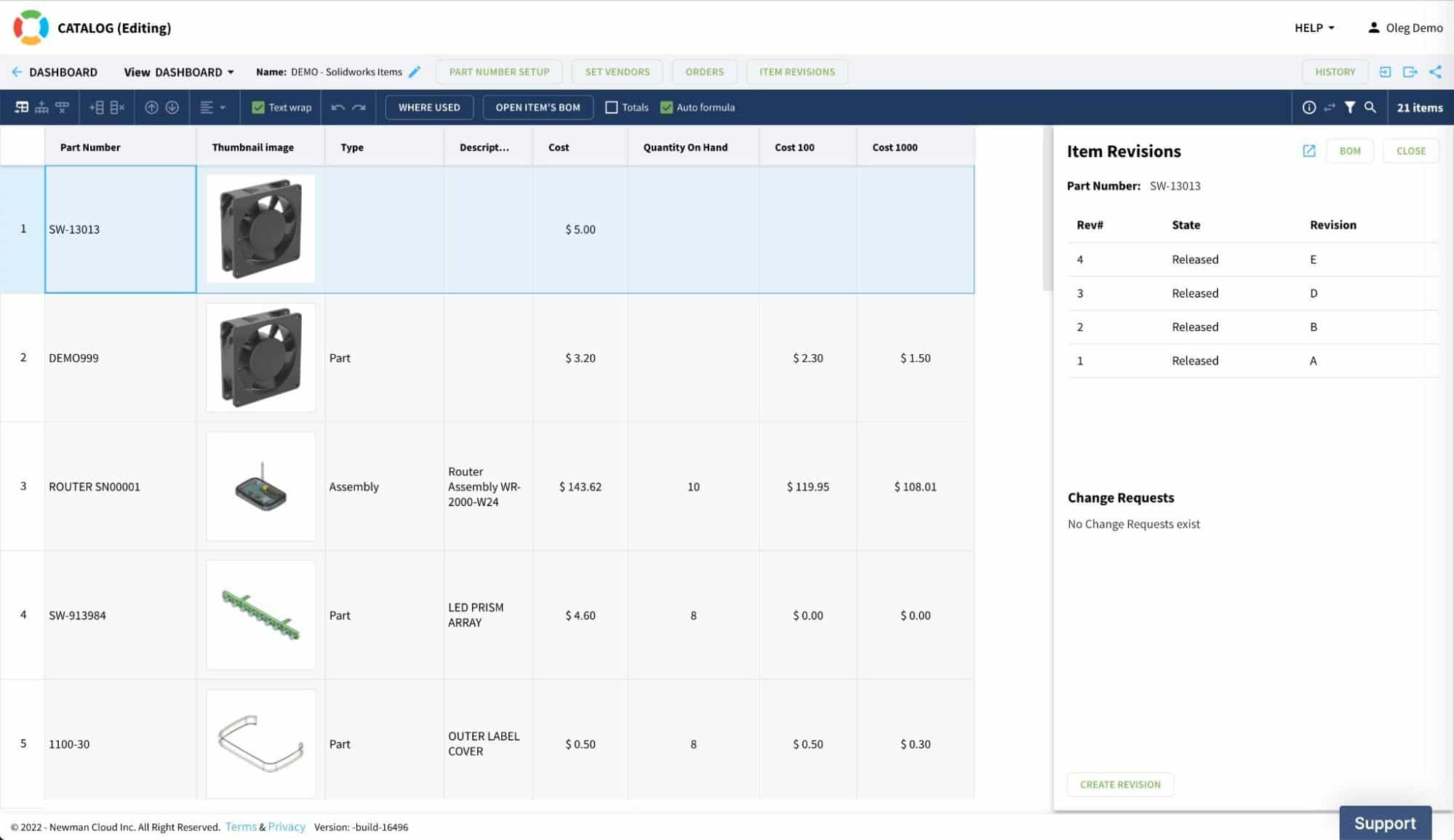

OpenBOM gives you an out-of-the-box system ready to capture the history of all changes, create revision baselines and organize the change management processes with change requests, orders, and approvals. OpenBOM manages an entire history, revision list including all data connected to items (eg. files and other parameters).

Items Revisions

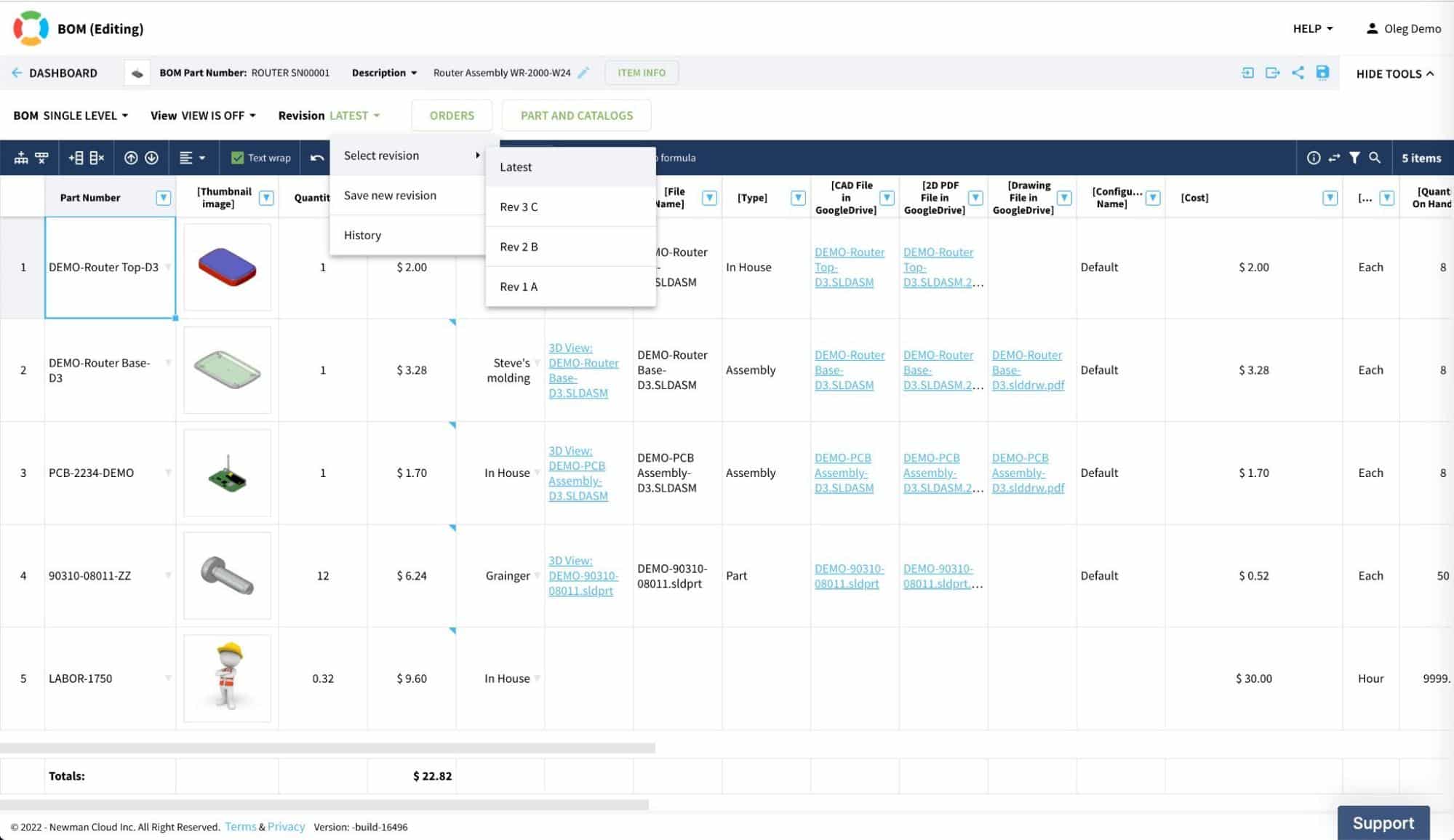

BOM revisions and History

Conclusion

Don’t trust your product data to Excels. It will be lost, corrupted, and you will not be able to track duplicated records. You cannot manage structures, perform roll-ups and other calculations as well as perform and track changes.

OpenBOM gives you a simple yet robust and flexible solution to manage product information online in the way everyone on your team will get access to the data.

Check out what OpenBOM can do for you – REGISTER FOR FREE and start your 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.