In today’s world, time is money. That’s why manufacturing companies are always looking for ways to streamline their processes and reduce the amount of time it takes to get products from design to production. However, it is very easy to say, but much harder to do. Modern manufacturing environments are presenting multiple challenges for efficient process management and collaboration such as distributed teams, multiple time zones, multiple organizational units, contractors, and suppliers. All these factors make process management and collaboration very difficult.

Engineering and manufacturing change orders are one of the best examples of how hard it is to manage an approval process between multiple people and organizations. At first, it sounds like a simple task – create a change order, add information about parts or assemblies you want to change, and then send it out for approval. However, it is not that easy.

Traditional PLM Workflow Challenges

A traditional PLM Workflow is a tough balance between value and complexity. Workflow is a reflection of the real process. The ideal workflow is a good starting point, but you need to get your hands dirty with workflow details. This is a reality and a problem of analog PLM paradigm – your tools are as good as the process and customization you do. Workflows are easy to start. Especially using graphic diagramming tools. But you can quickly run into the complexity of the implementation and the reality of your organization. People are running product development and manufacturing process. Customers are likely to dump your workflow implementation if it will add an additional level of complexity to organizational process management.

Here is a simple example. An engineer creates the ECO in the engineering software. Next, the engineer sends an email notification of the new ECO to all stakeholders – management, purchasing, production, etc. Each stakeholder has access to a digital form where they can review the ECO and provide feedback. Once everyone has had a chance to review and comment on the ECO, it can be approved. The process is basically mimicking a traditional paper form process, but place it in the digitized format.. This is how the legacy PLM approval process works. Email is king and the workflow that drives the process should ensure that the process won’t get stuck.

The problem we’ve seen in many traditional workflow implementations is that they are rigid and provide little to no visibility on what is happening as well as have the flexibility to adjust and modify it. So, workflows are hard and we at OpenBOM realized that we need to bring a better way to change traditional workflow processes needed for approval processes.

Collaborative Workflows and Approvals

At OpenBOM we developed unique technologies and patented methods helping engineers and manufacturing companies to collaborate in real-time. If you’re using OpenBOM now, I’m sure you know how you can share data in real-time and keep everyone connected and updated about all information you manage in the product. OpenBOM keeps your extended team including contractors and suppliers on the same BOM.

We decided to bring the same method and help manufacturing companies to re-invent the ECO process by turning it into a flexible, collaborative, and powerful approval process. And this is what we did in our new collaborative ECO approval workflow. In the video below you can see a quick intro to OpenBOM collaborative approvals just in 90 secs.

Change Order Approval Process 101

There are three elements of OpenBOM approval workflow: (1) role-based settings; (2) change request for each item/BOM revision; and (3) sign-off dashboard. Let me show you these three elements.

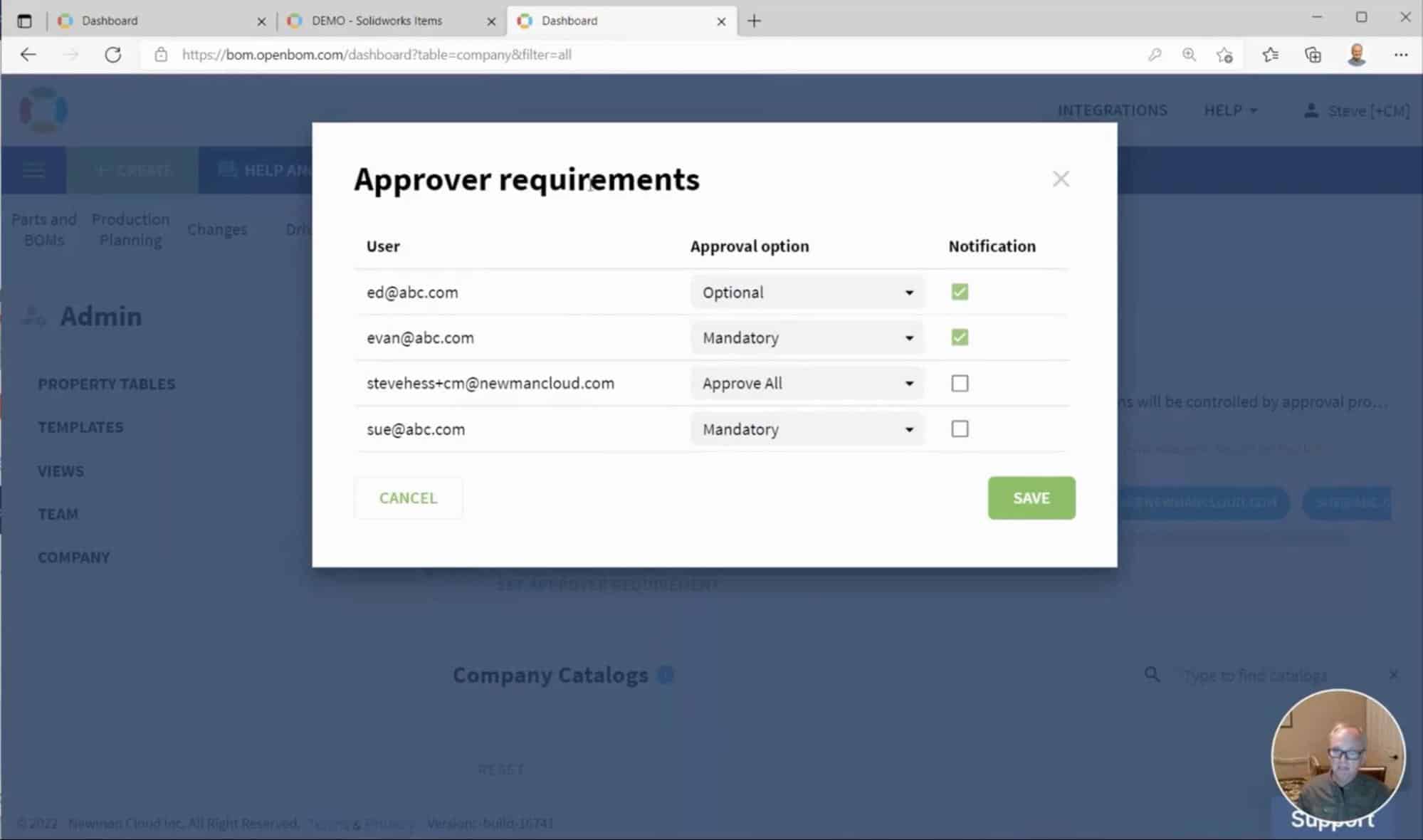

Role-Based Approvals

In OpenBOM you can define 4 levels of approval settings: 1- Notification; 2- Optional; 3- Mandatory; 4- Approve All.

Each of them allows you to set people’s roles in a way that will help them to perform their work either by observing change processes or taking an active part in them. Approval All is a super powerful role that allows the person to override everyone else and make things move forward.

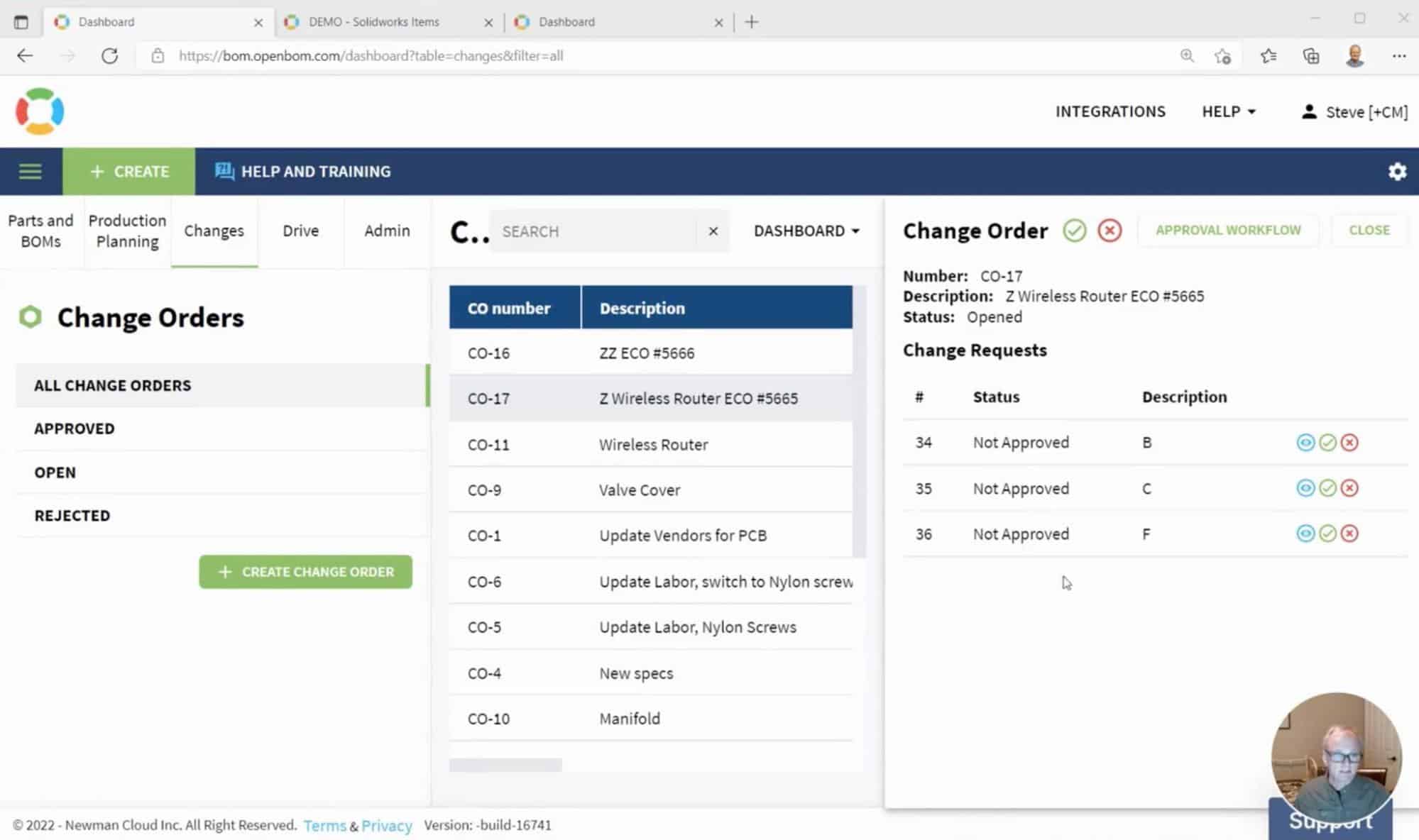

Change Order and Change Requests

Change Order and Change Requests are allowing you to create a group of changes that will be going through the approval process. Each change request is connected to Item/BOM revision that can be combined in a group of changes managed under the same CO.

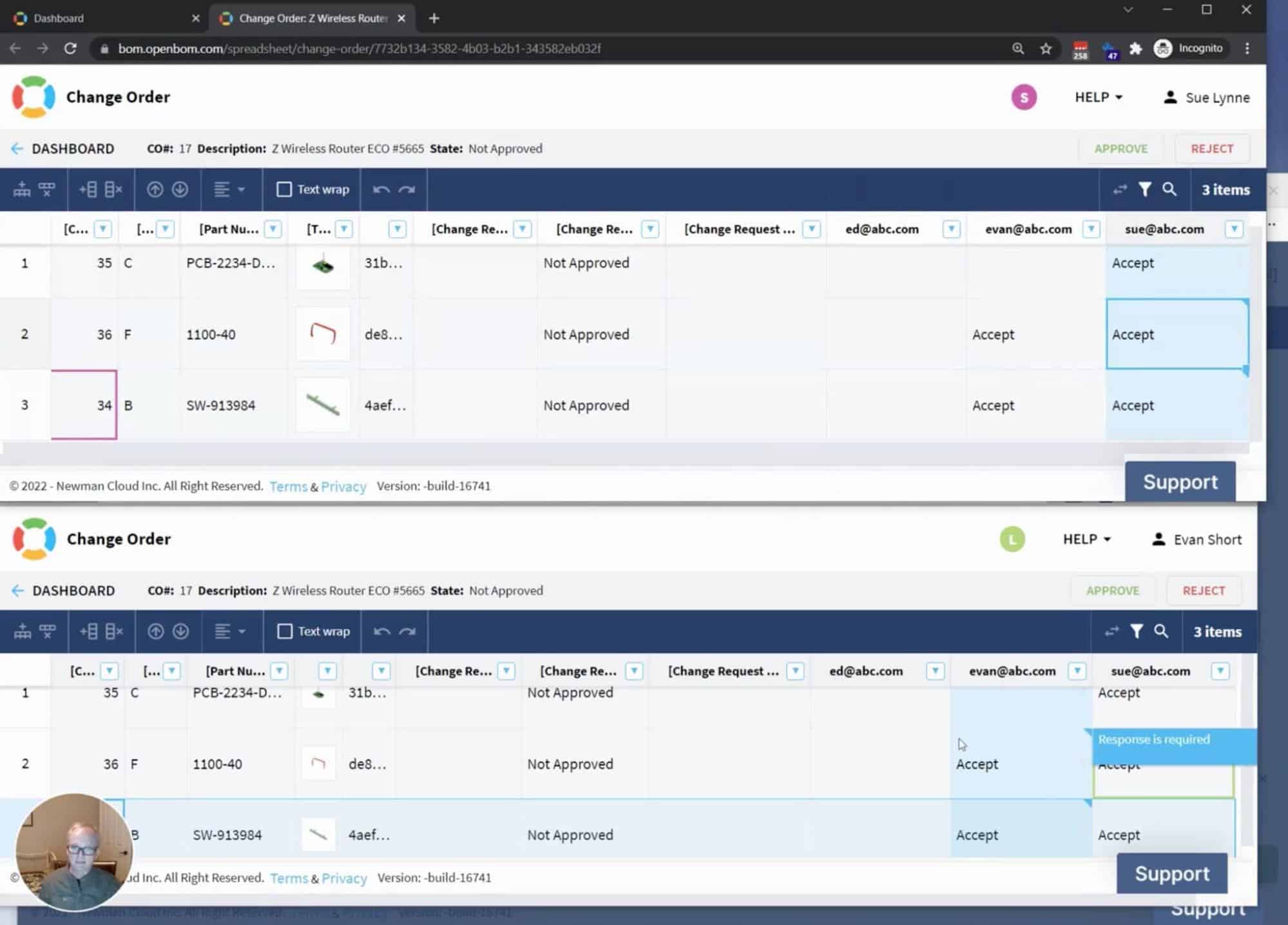

Collaborative Sign-off Dashboard

The last element in the OpenBOM collaborative approval workflow mechanism is the sign-off dashboard, which allows everyone that needs to be involved in the approval process to see the approval status and make their approvals by operating in a single collaborative dashboard that is updated simultaneously and gives the top-level visibility to everyone.

Most importantly, the visibility of the approval mechanism is seamless and allows everyone including managers and all other team members to participate in it. The multi-tenant capabilities of OpenBOM allow you to bring people from different companies together for such an approval process easily without having to go through the complex email approval chains.

Video – Collaborative Change Approval in 90 sec

Finally, you can watch the video that demonstrates your OpenBOM collaboration in ECO, MCO, and other process approvals. I hope you enjoy it.

Conclusion

The recent OpenBOM innovation is to bring real-time collaboration technologies to PLM approval processes. The legacy PLM systems usually provide advanced and complex workflow mechanisms that are often very rigid and don’t fit well in the dynamic product development environments we can see these days. We allow companies to move faster and provide a modern collaborative approval process. In addition to its real-time sign-off dashboard, it allows bringing people from multiple companies together for an approval (thanks to OpenBOM multi-tenant environment).

Check out what OpenBOM can do for you – REGISTER FOR FREE and start your 14-day trial to explore all premium features.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.