If you’re a longtime citizen of engineering and manufacturing communities, you probably heard people saying that if you have 2 engineers, you might have 3 opinions about how to do something. It is especially true when it comes to discussions about how to organize and manage data. At OpenBOM, we knew from a very early beginning that flexibility and ability to configure application are two main things for engineers and manufacturing to work with Bill of Materials, Catalogs, Vendors and Order planning.

Nevertheless, I’ve been asked many times about OpenBOM best practices on how to manage data. So, today, I want to outline it for the first time. Please remember, this is my “take 1” and I’m sure refining and clarifications will be coming. And don’t hesitate to criticize and comment.

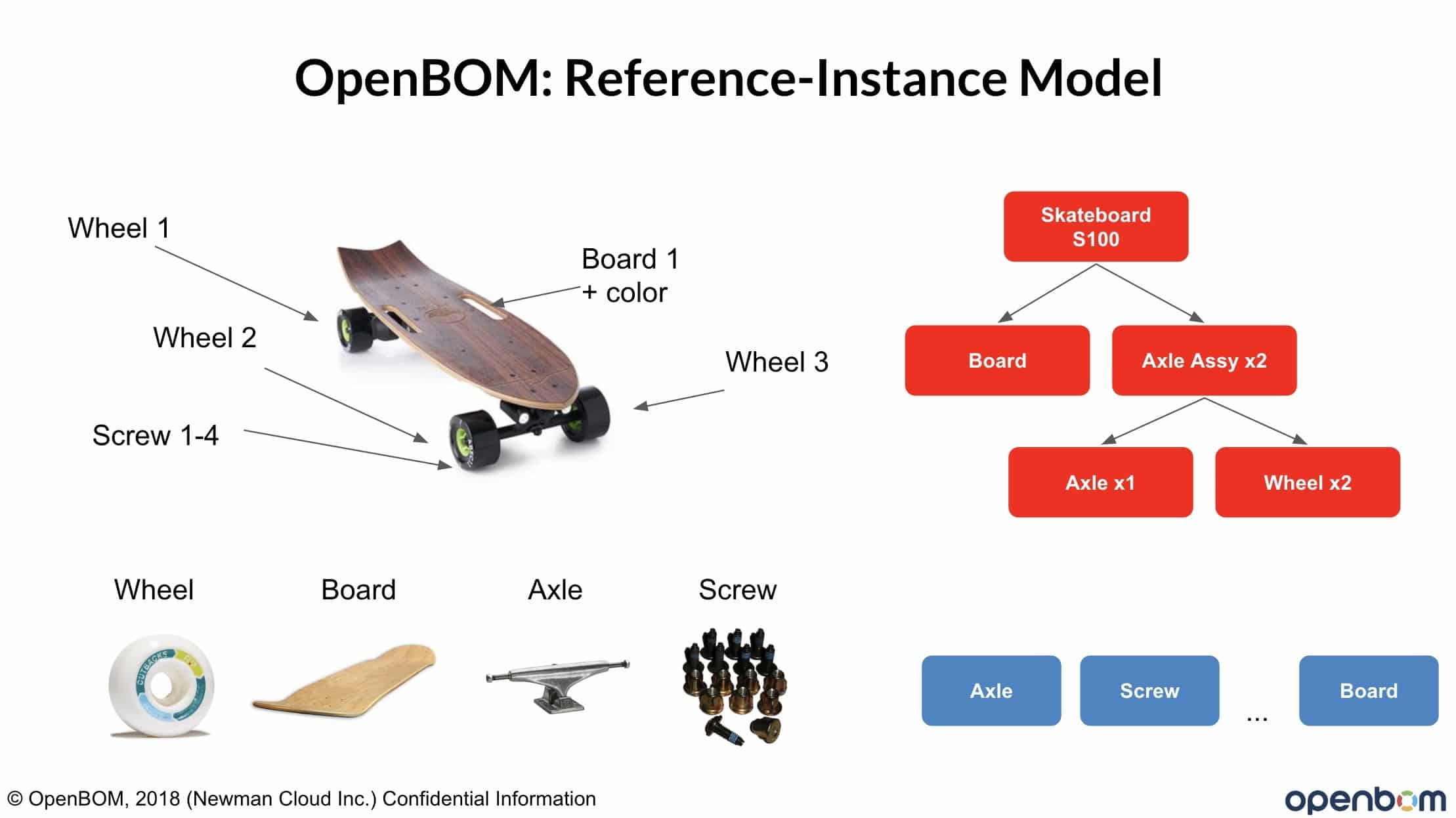

OpenBOM™ Reference-Instance Model

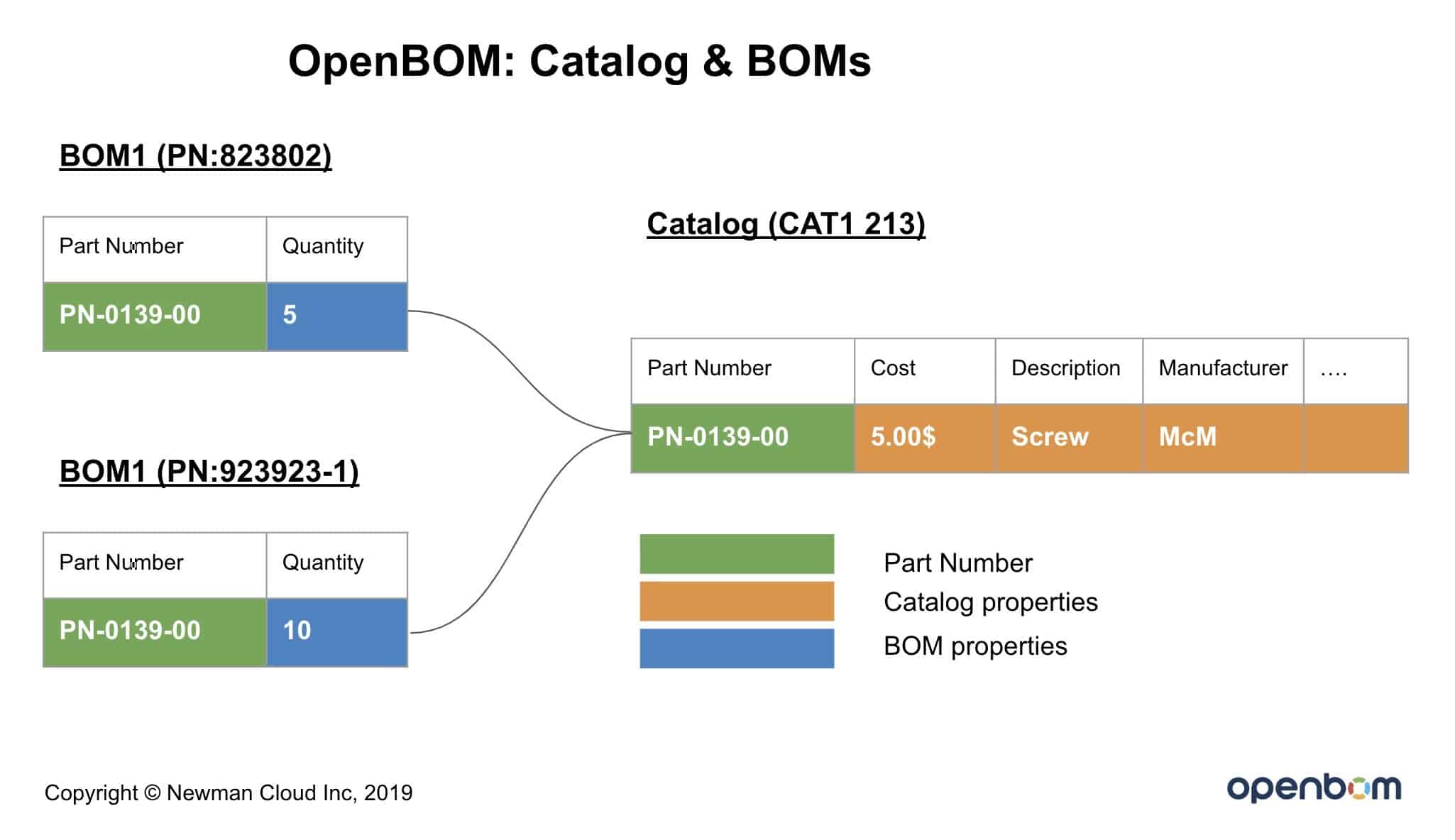

The most fundamental part of OpenBOM data management is the reference-instance model allowing to manage catalogs of items with the master item (Part) data and instances (BOMs) for specific products, bill of materials and structure.

The following image can remind you how reference-instance model is implemented in OpenBOM by catalogs and BOMs. Note (very important) level of flexibility. OpenBOM allows you to extend both reference and instance model on the fly by attaching any new attributes on BOM and catalog level.

So, what is the right way to manage data in OpenBOM? Should you create BOMs or Catalogs first. Does it make sense to manage BOMs with no catalogs? What is the navigation options between BOM and catalogs? How data is updated?

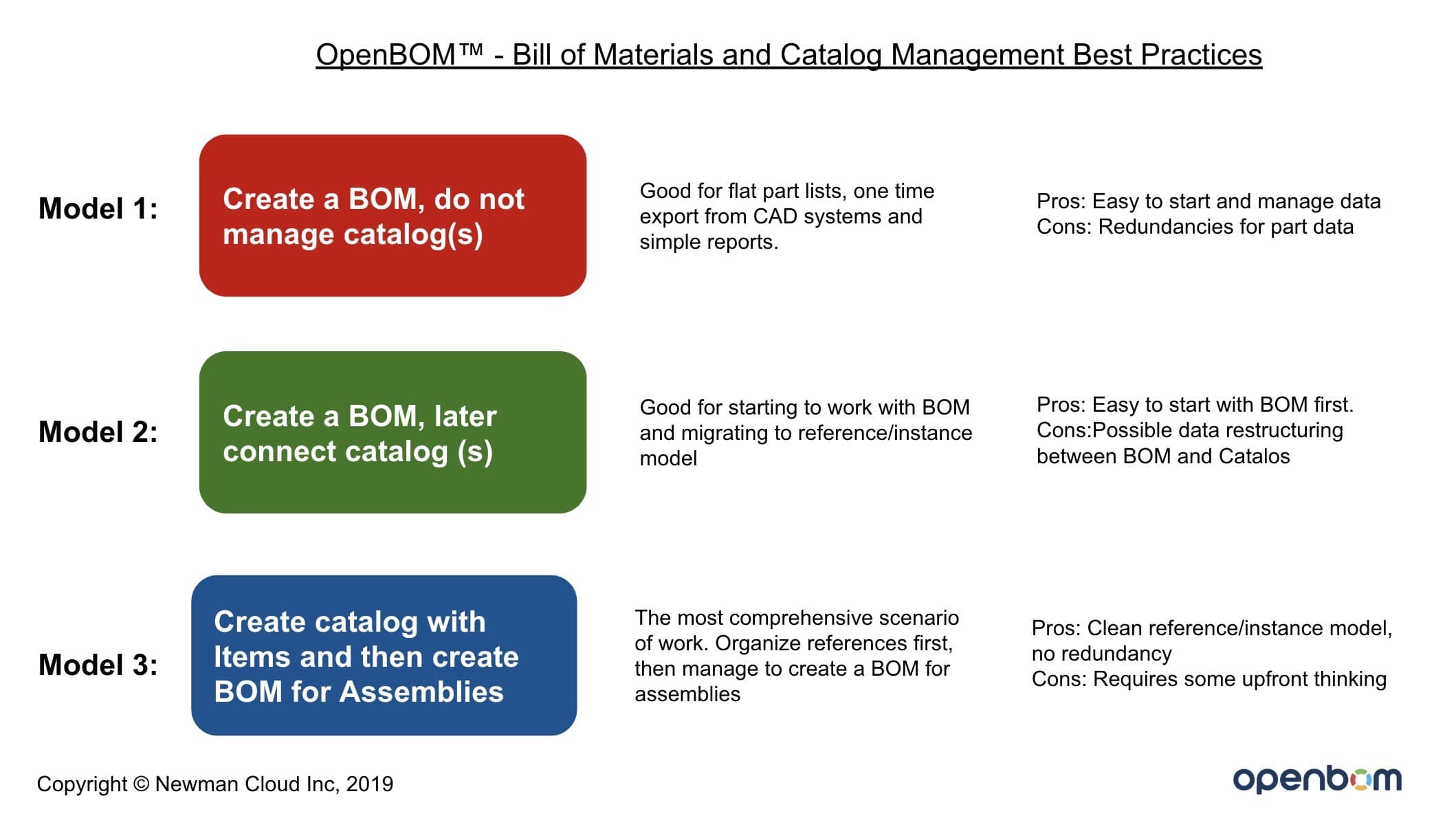

These and some other questions I plan to answer using my first edition of OpenBOM best practices. The picture below shows you 3 possible options (model).

The first model is a simple flat BOM created (or imported from a spreadsheet). Not much sophisticated, but it gives you an ability to track history, share data and make calculations.

The second model is what was the main option to create a BOM in OpenBOM. However, new release gave few additional options, such as create a BOM with already assigned catalog. It gives much-wanted simplification when you create a BOM (no need to go and assign catalog).

The third option is the most comprehensive and it just became available in the last June 9th release of OpenBOM. You can now create a BOM directly from BOM catalog item. The advantages of this mode are that together with the most comprehensive data model organization it simplifies the workflow and eliminate the need to double enter BOM Part Number and Catalog after and during their creation.

I hope you like these options. Below is a summary table, pros, and cons.

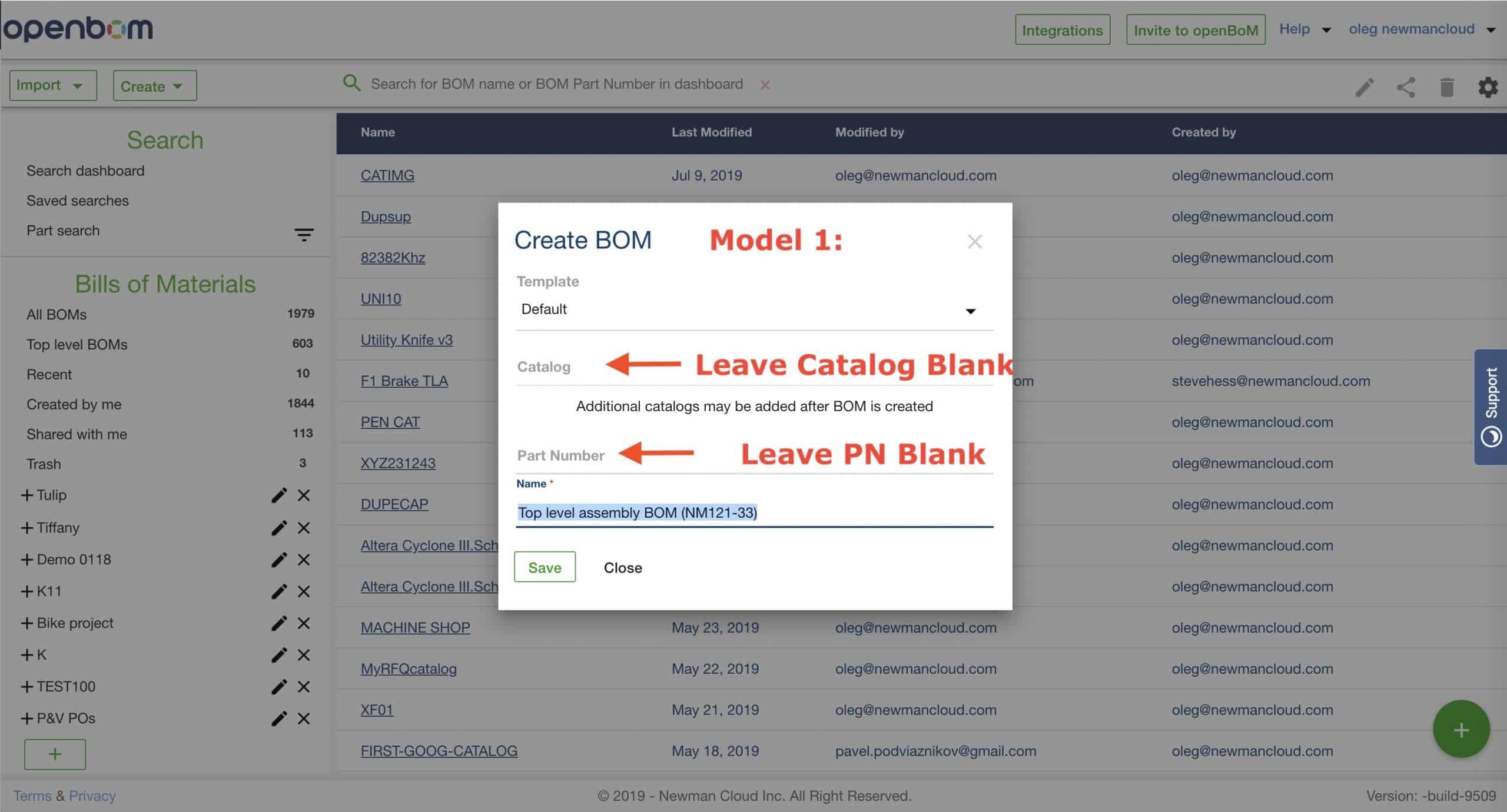

Below please find some examples how these 3 models can be used in OpenBOM user interface.

Model 1:

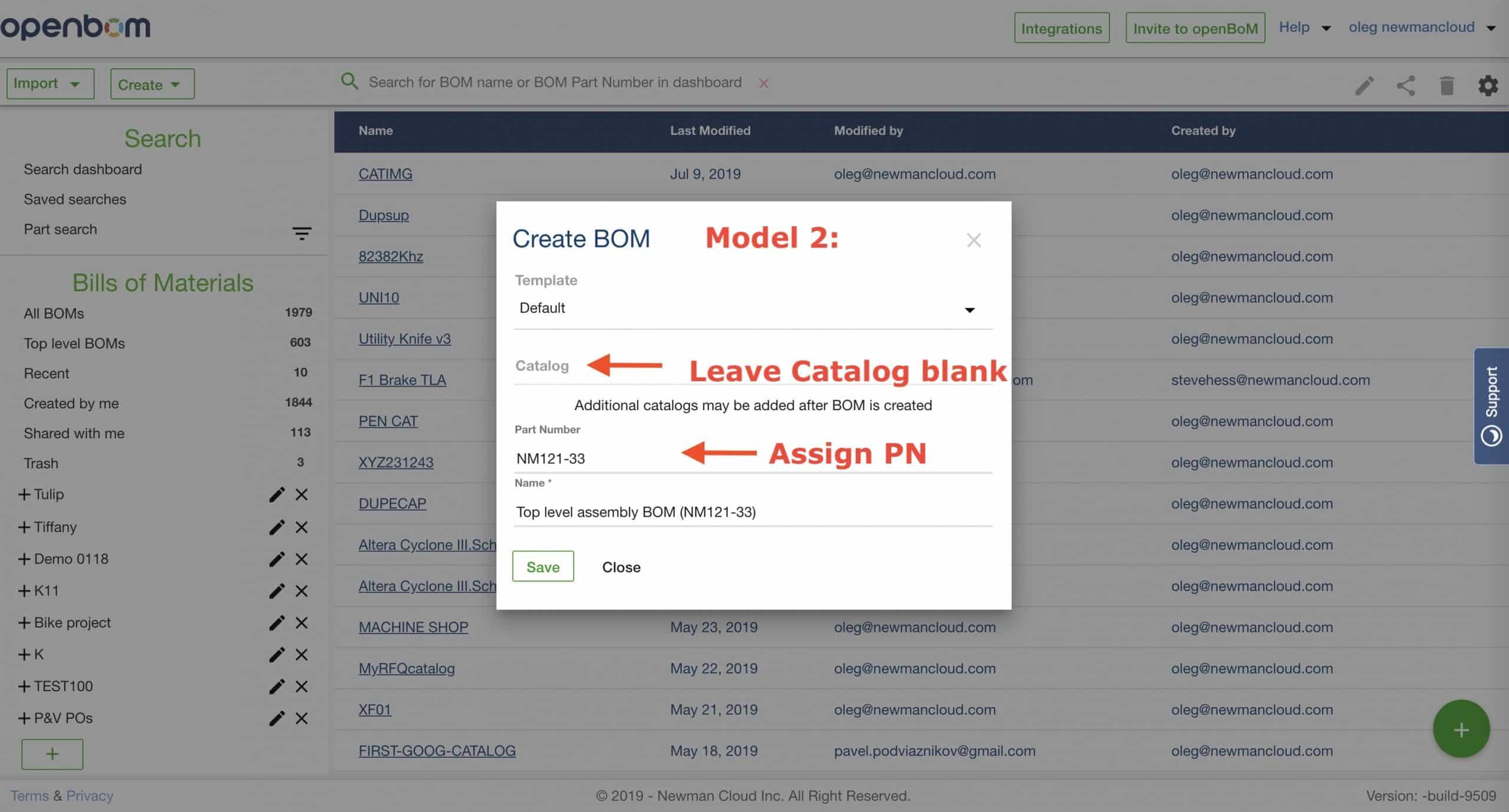

Model 2:

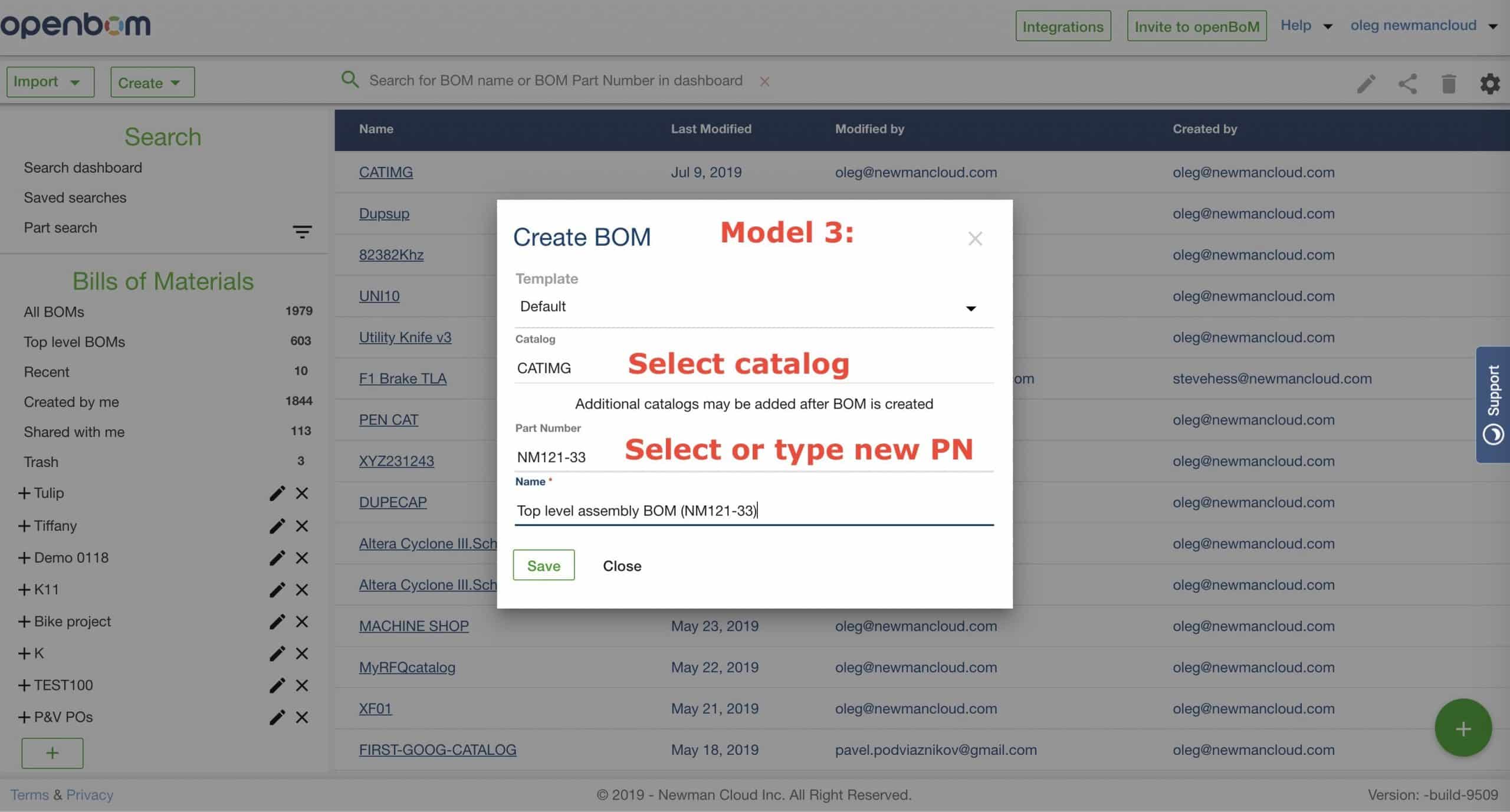

Model 3:

This is one option to do so via “New BOM” dialog.

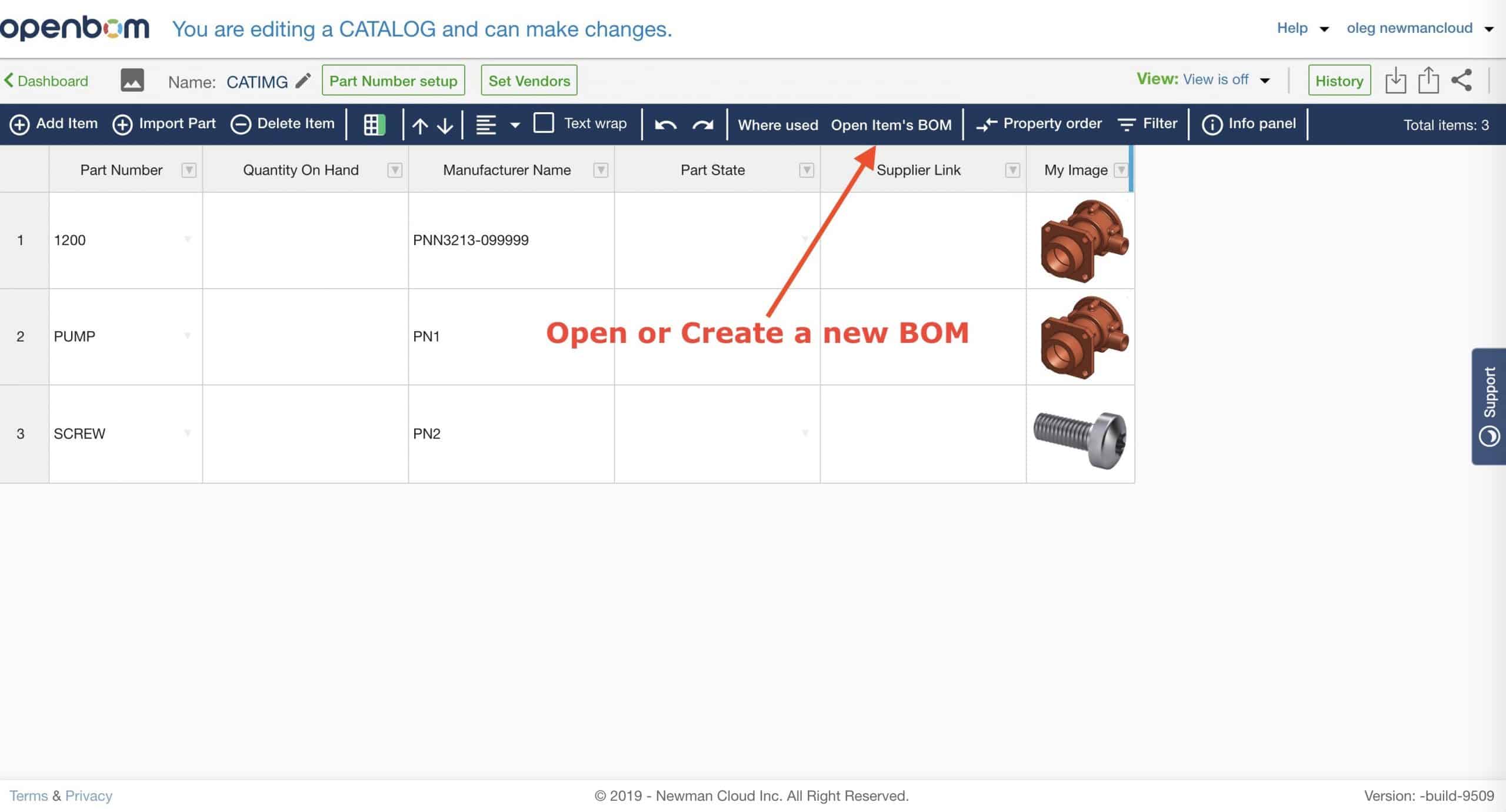

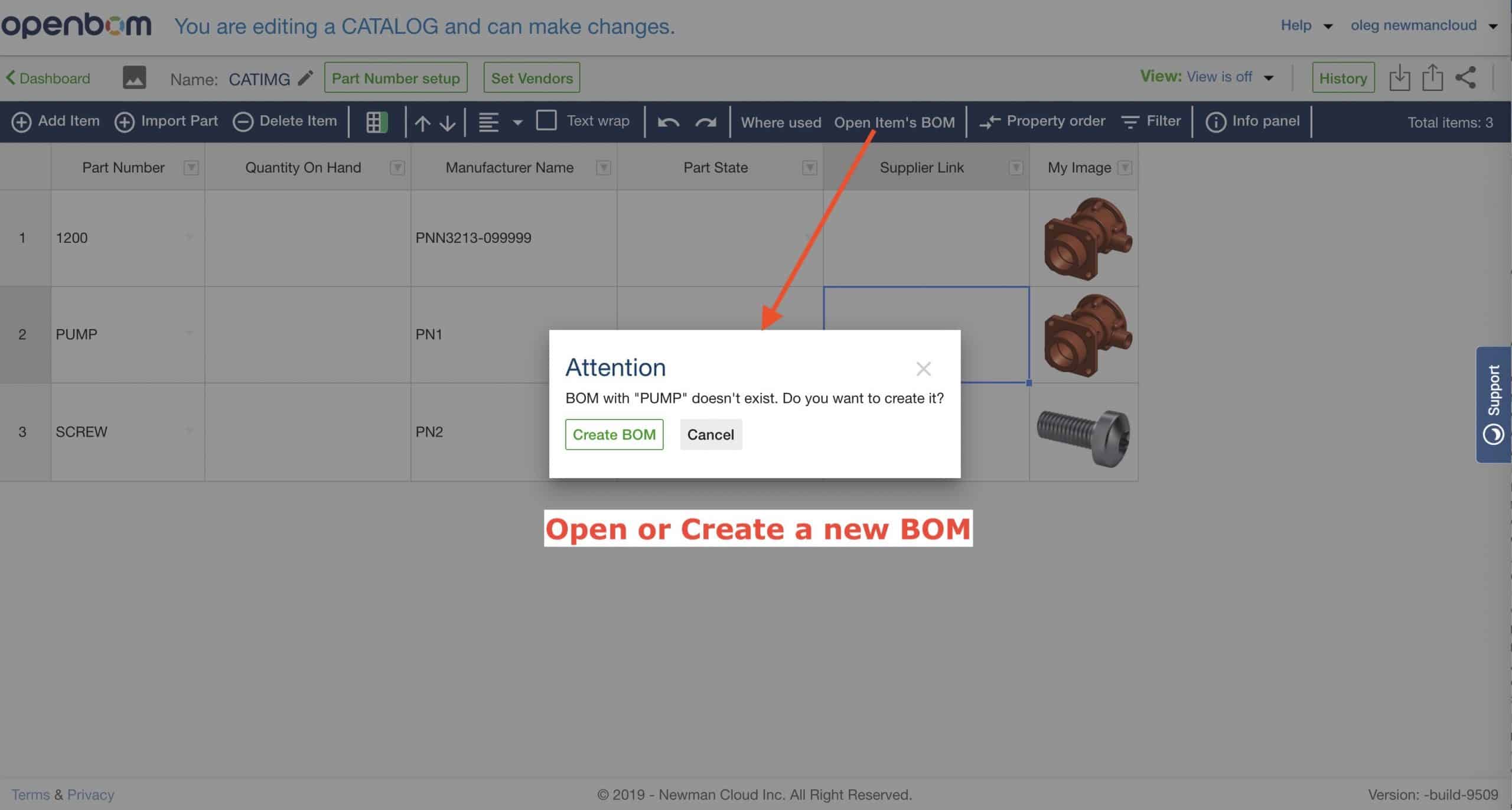

An alternative option is to create a BOM directly from a catalog.

Conclusion.

OpenBOM reference-instance model implemented using BOM and Catalogs is super flexible and allows a lot of space to customize on the fly data model and make changes in the way structure is organized and calculations are done.

OpenBOM is a sophisticated, powerful and, at the same time, very simple system. You can use BOM and catalogs for a variety of use cases. Follow model 1-3 to manage your data. Please let me know if you like it and what is missed. In

In my next article, I plan to speak about Best Practices of creation of BOMs from CAD systems. Finally, I will be coming with calculation best practices. Stay tuned.

Best, Oleg

PS. Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.