Managing engineering and CAD data is hard work. PDM and PLM have been around for more than two decades, yet, managing files, capturing correct information from CAD files, generating Part Numbers, creating a Bill of Materials, and creating a catalog of components and final products can be daunting tasks.

Making Complex Tasks Simple

At OpenBOM, we took on the challenge of simplifying this process and providing a simple yet powerful and robust online service that can be available for every engineer and industrial company to help manage product information, capture the data from design, and make this data available downstream to your organization, contractors, suppliers, and customers. On top of this, we help customers manage an entire process of engineering and manufacturing changes, production planning, and procurement.

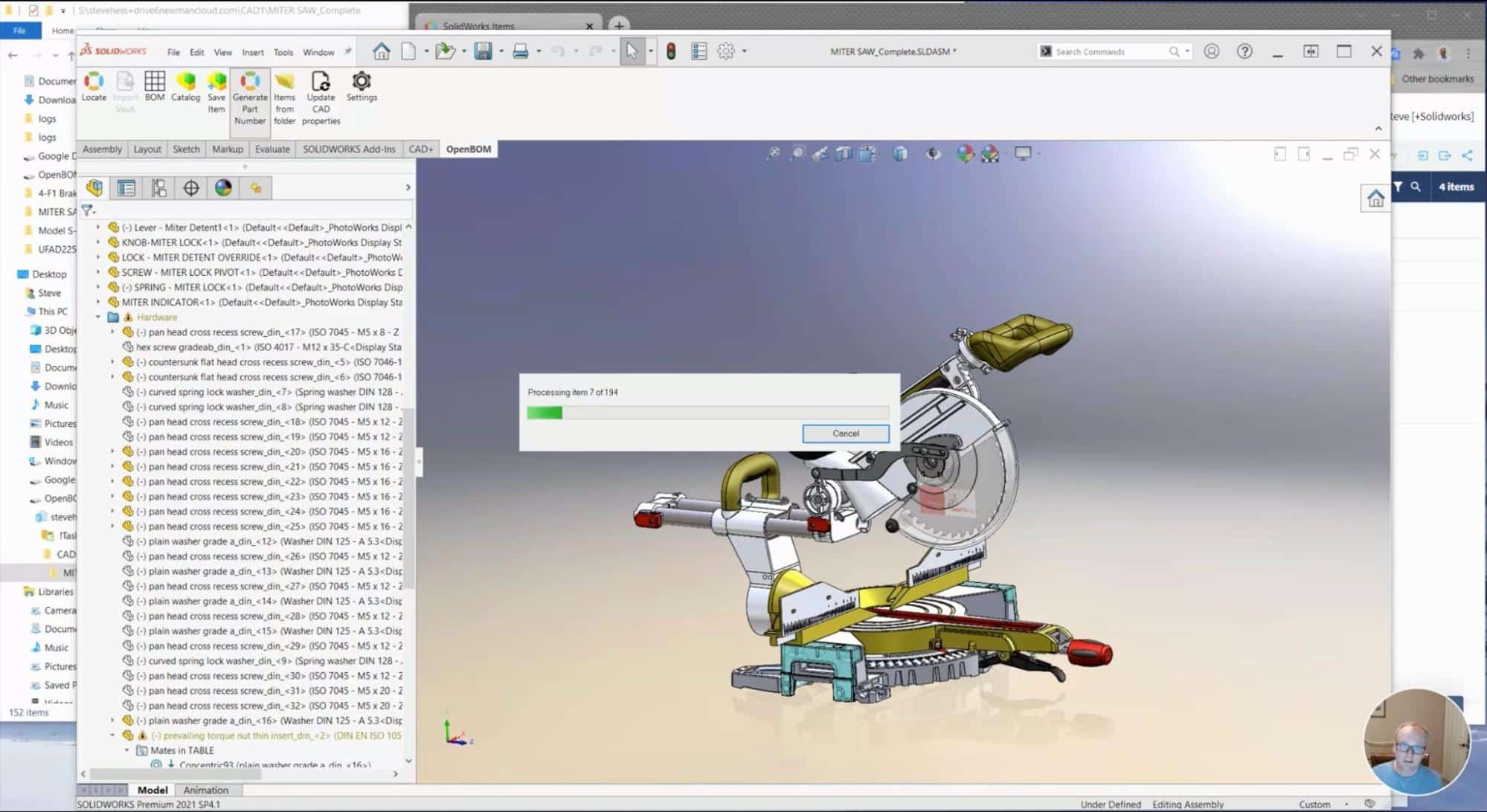

In my article today, I want to finish on the first step in this process – how to manage files and capture all information from the CAD system. In the video below, OpenBOM Director of User Experience, Steve Hess will take you in real-time during the process of capturing information from Solidworks assembly, including all tasks involved to get the data under control.

Data Management Steps

- Seamlessly manage files using OpenBOM Drive (check more about it here)

- Configure catalogs to classify CAD data

- Assign Part Numbering schemas

- Configure OpenBOM for Solidworks add-in settings

- Automatically generate Part Numbers for all assemblies and parts

- Create a full product structure (BOM) based on flexible settings (extract only attributes you need from Solidworks)

Video Demo

This entire process takes a little bit over 10 minutes, check it out below.

Conclusion

At OpenBOM we focus on simplifying processes and we start from the most important one – to capture data, organize information (eg. classification, part numbers, etc), manage files (new!), and create a fully functional product structure with all attributes, files (CAD files), derivatives (eg. STEP and PDFs) and ability to use this data for calculations, planning and procurement.

Everything we demo is available for you with a single click. You can register for FREE, start a trial, install OpenBOM Add-in and get it done in under one hour. We are always happy to help you with consulting and onboarding training.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.