Managing product data is a critical part of any successful manufacturing operation. In order to make informed decisions about where to allocate resources and how to meet production goals, manufacturers need accurate and up-to-date information about the products they produce. This is where OpenBOM comes in. OpenBOM provides users with unparalleled flexibility and scalability when it comes to data management. With its customizable interface and wide range of integrations, OpenBOM can easily adapt to any production environment. Whether you are manufacturing a single product or thousands, OpenBOM has the tools you need to get the job done. In my article today, I will explain the unique characteristics of OpenBOM data management.

Databases and Data Management Foundation

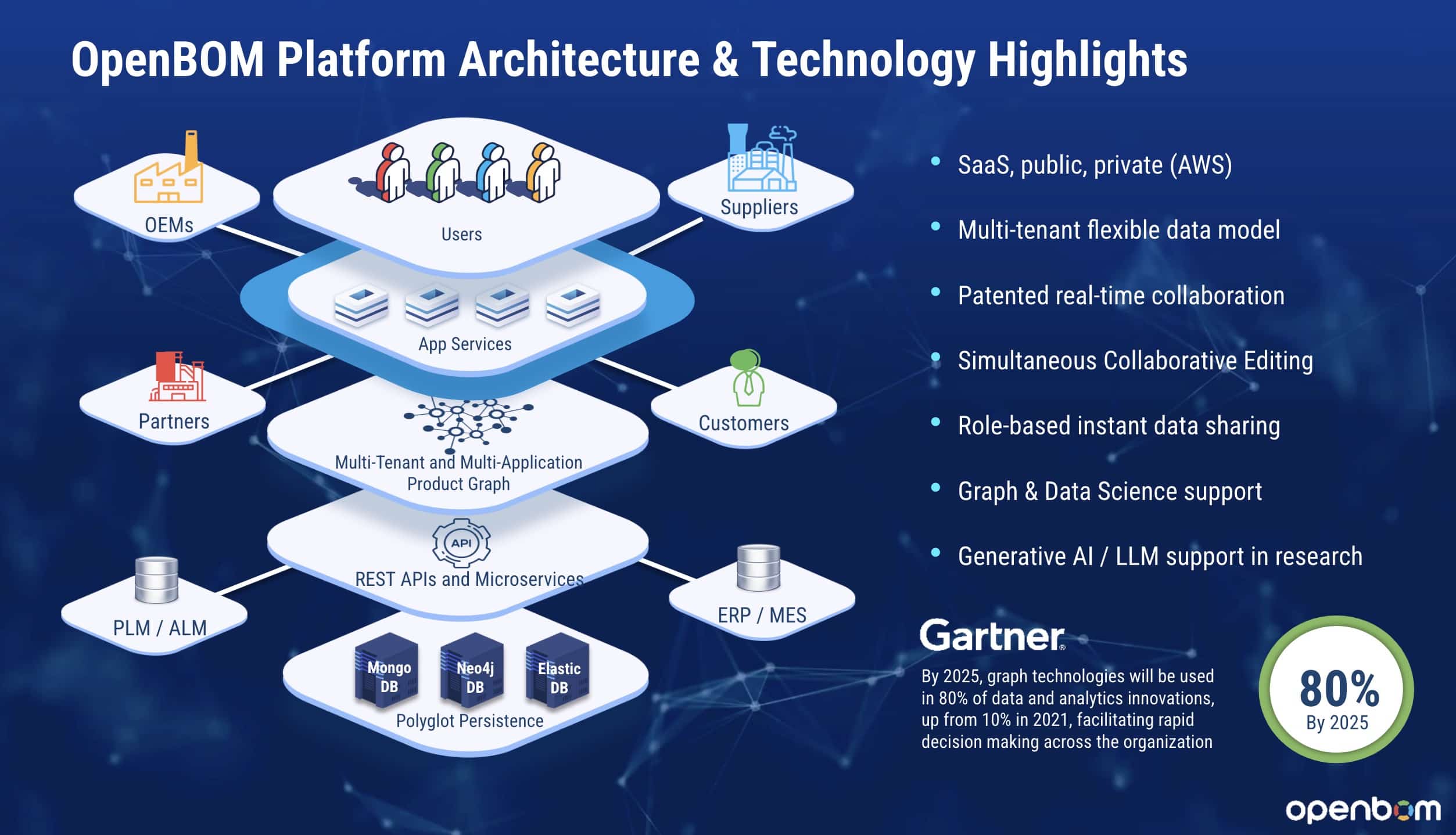

OpenBOM data management platform is using robust and scalable computing and data management foundation. OpenBOM data management foundation relies on polyglot data architecture and uses multiple databases to scale its online services.

In our event Demystifying Modern PLM, we discussed how OpenBOM is using a combination of databases such as MongoDB, Neo4j, Elastic, and some others to provide a flexible data management environment.

Product data is highly structured and requires a robust, scalable, and semantically rich foundation to manage relationships. Therefore, Graph Database plays a special role in OpenBOM data management architecture.

Logical Data Model, Flexibility, and Semantics

OpenBOM is designed with a demand for flexibility and needs to support multiple engineering needs and requirements coming from different manufacturing companies.

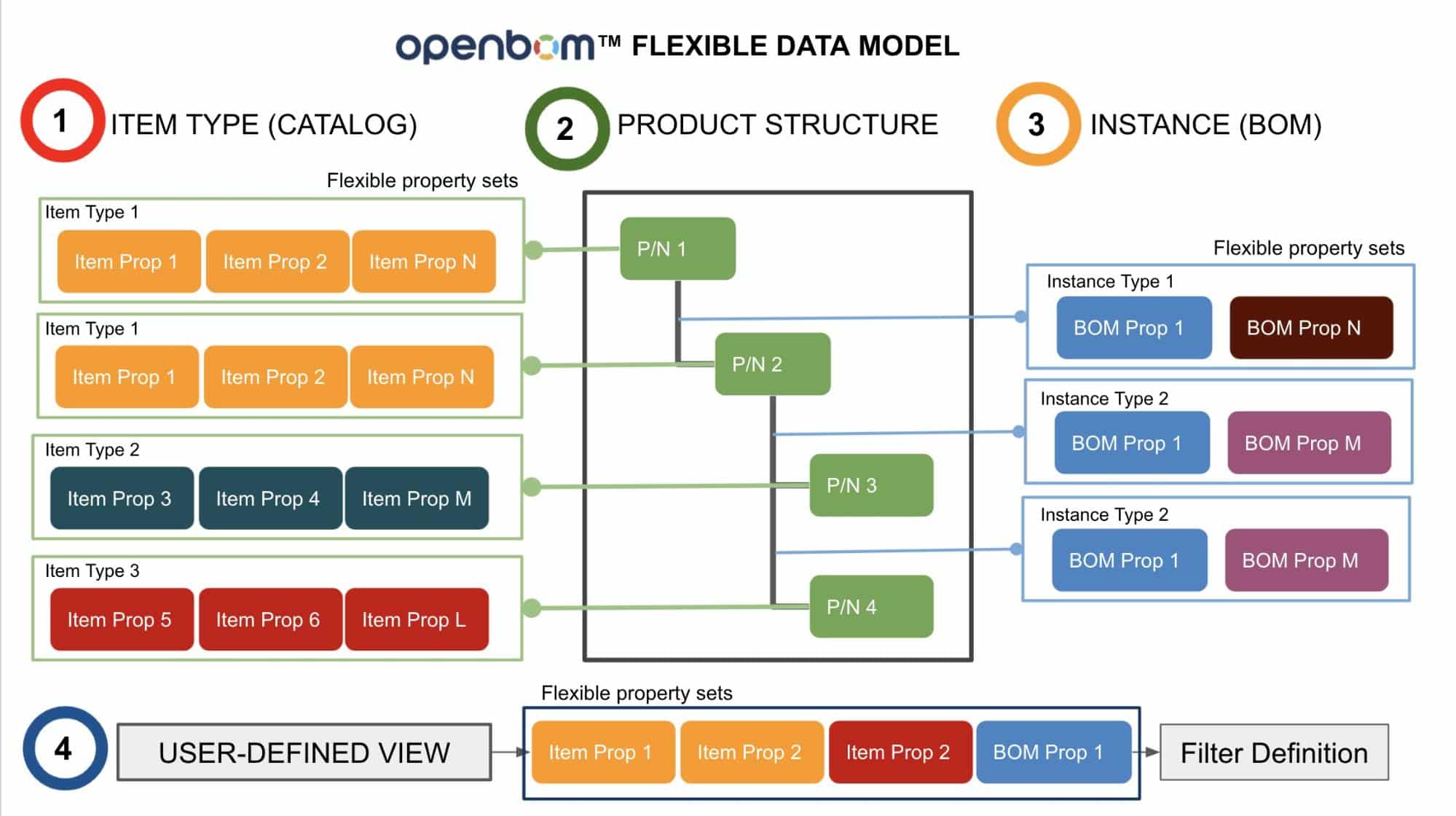

The core logical data management foundation of OpenBOM is based on the following definitions – (1) property; (2) object type; (3) product structure and (4) relationships. OpenBOM supports multiple property types that provide a foundation for any data model created in OpenBOM.

The following picture represents a schematic chart explaining the OpenBOM Data Model. You can already see familiar concepts, but I want to summarize what OpenBOM’s data management platform is capable of and most importantly how it can be flexibly adapted to any type of information that can be used by manufacturing and construction companies.

Learn more about OpenBOM’s Flexible Data Modeling best practices in the following articles – Part 1, Part 2, Part 3, Part 4, and Part 5.

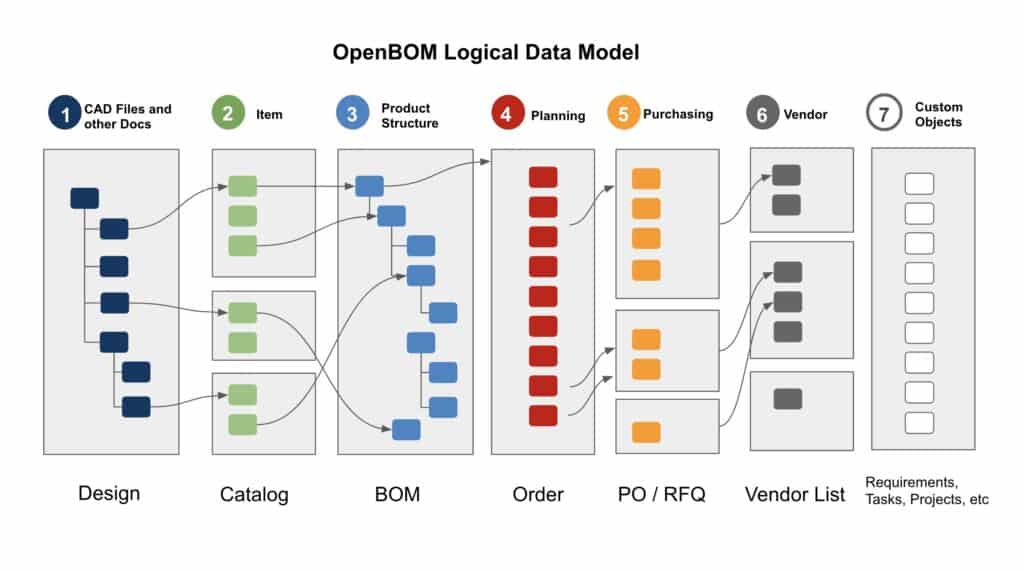

Business Objects

OpenBOM logical data management platform provides a foundation for the creation of custom business objects. These business data objects are used in OpenBOM to create data, to support data management and business workflows. In the picture below you can see a logical model representation of all OpenBOM business objects.

You can learn more about OpenBOM business object foundation and support business process by navigating to this article – Understanding of OpenBOM.

Microservice Architecture

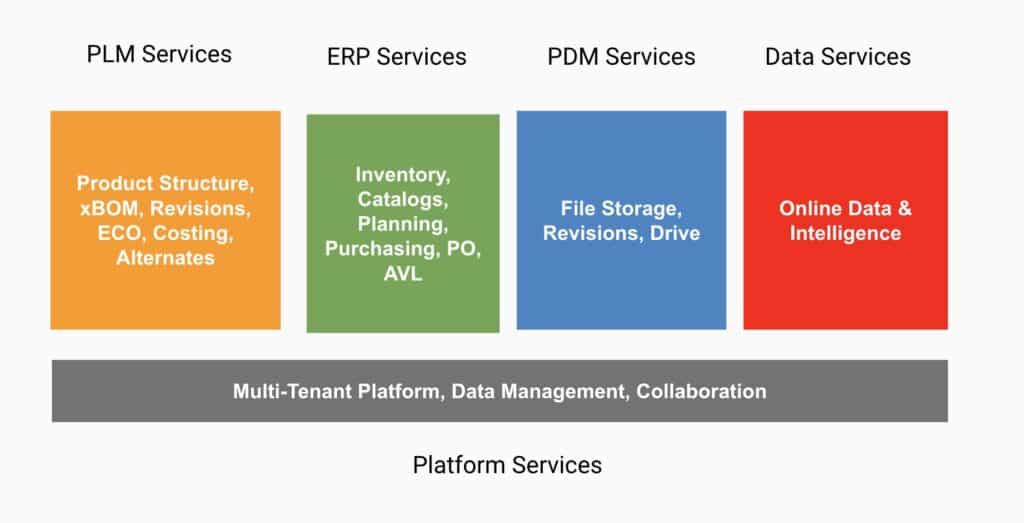

OpenBOM platform is built using a micro-service architecture. The following article gives you a high-level representation of OpenBOM services. All services are available via REST API and can be used to enhance the OpenBOM platform with additional applications and integrations.

Multi-tenancy and Deployments

An important element of OpenBOM architecture is its tenancy model. OpenBOM platform has both data and system multi-tenant architecture. The picture below shows the main difference between single-tenant and multi-tenant architecture.

OpenBOM multi-tenant architecture opens a full scale of flexibility in OpenBOM deployment. OpenBOM public multi-tenant instance (openbom.com) runs on the AWS platform and is available globally for everyone via subscription. Everyone can get an account by registering on OpenBOM.com, creating an account, and subscribing to OpenBOM services using OpenBOM subscriptions (pricing is here).

At the same time, the OpenBOM platform instance can be installed individually in a separate AWS account belonging to a specific manufacturing company (eg. OEM) and use its multi-tenant architecture to serve a group of the companies – eg. Tier1-n suppliers of OEM. Read more about it here – OpenBOM Web Services.

Conclusion

OpenBOM developed a scalable and flexible data management platform that can serve manufacturing companies of different sizes. Its robust data management architecture and micro-service architecture is under ongoing development and expanding to follow OpenBOM’s business and functional goals to scale and serve engineering teams and industrial companies of different scale and geographical locations.

Have questions about OpenBOM architecture? Want to integrate or use OpenBOM as a foundation for your applications? Please contact OpenBOM support and we would be happy to arrange a web meeting to discuss this.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.