At OpenBOM, our mission is simple yet profound: to help companies build products faster and more efficiently using accurate organized digital data. In our new “Day in the Life” video, we showcase how OpenBOM’s powerful features seamlessly integrate into the daily workflows of engineers, managers, project coordinators, and procurement specialists, driving collaboration, accuracy, and efficiency in product development.

OpenBOM’s Vision: Building Products Faster with Accurate Data

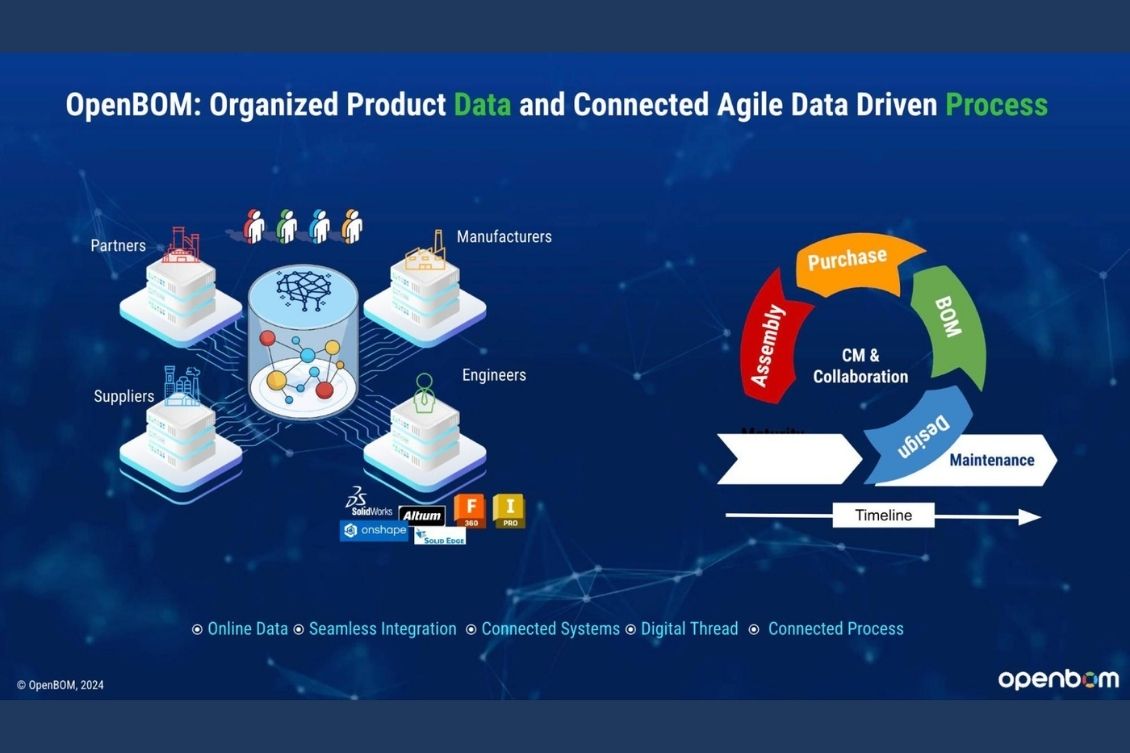

The heart of OpenBOM lies in its commitment to digital transformation. We focus on organizing and leveraging information to help companies work smarter and faster. By putting data at the core, OpenBOM ensures every decision is based on accurate, up-to-date information. This commitment to data organization empowers engineering and manufacturing teams to reduce errors, streamline processes, and accelerate product development.

Intuitive Access to Product Information

OpenBOM simplifies access to product data through its browser-based interface. Designed with collaboration in mind, the interface feels familiar—like a Google spreadsheet—but is far more powerful.

The Digital BOM (Bill of Materials) sits at the core, combining all product information into a connected and intuitive structure. Links between components create a web of organized data, making it easy to navigate, share, and collaborate across teams.

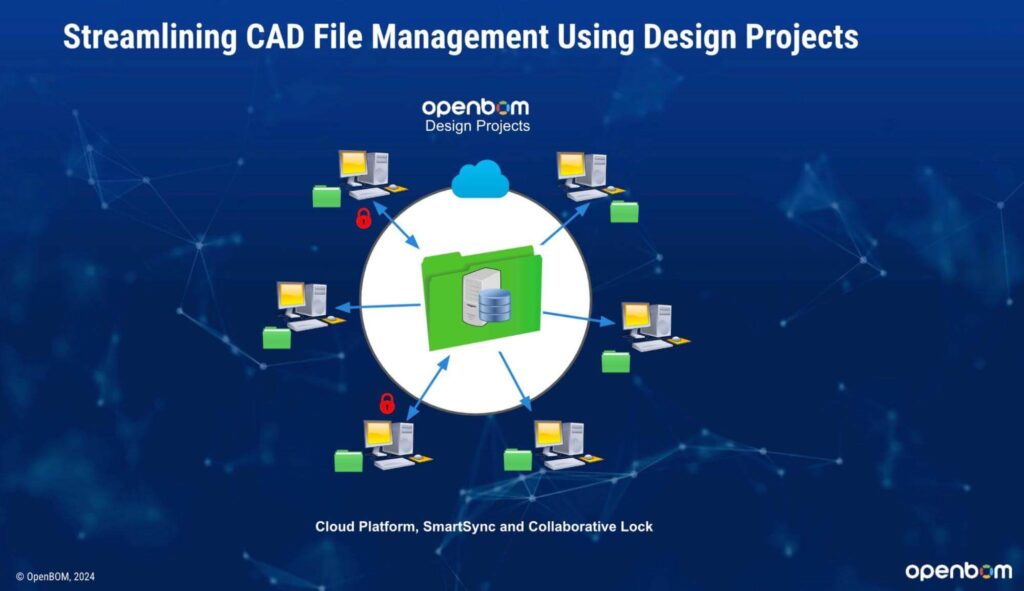

Managing Design Projects with the Workspace Manager

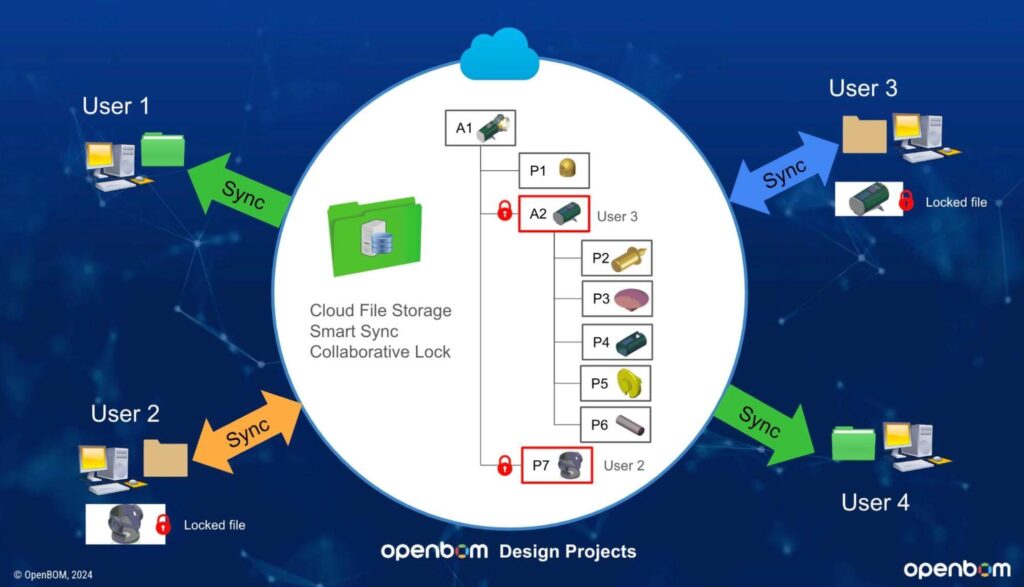

Our Design Projects service bridges the gap between local CAD files and cloud-based collaboration.

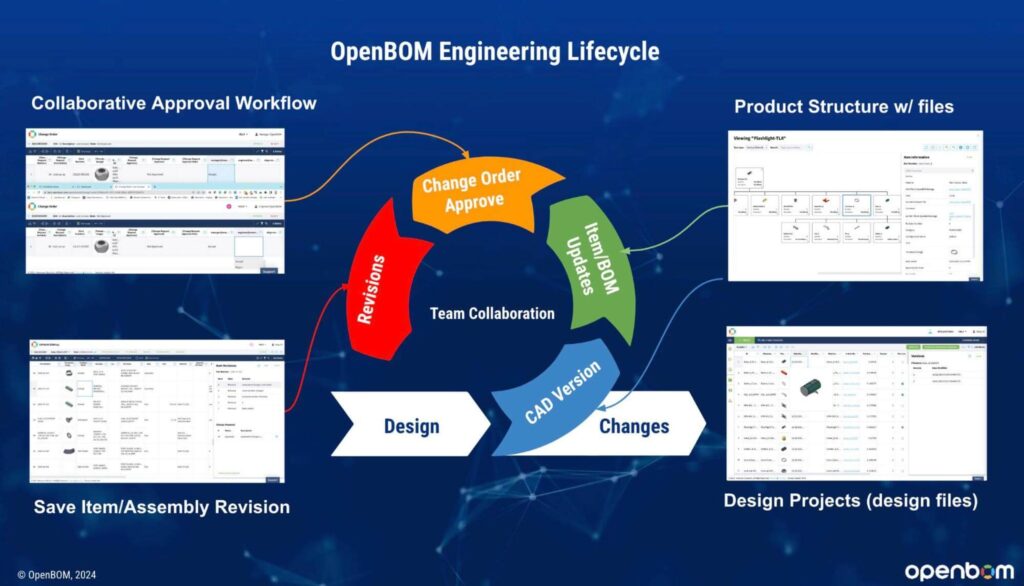

Using the Workspace Manager, engineers can effortlessly sync data to the cloud, enabling real-time access for team members. OpenBOM’s collaborative lock functionality prevents simultaneous edits, ensuring data integrity while allowing teams to work together seamlessly.

Automatic Digital BOM Creation from CAD

The transition from design to production starts with the Digital BOM. As soon as the project reaches its initial readiness stage, OpenBOM automatically generates a Digital BOM from CAD data. This process captures all critical properties, derivative files, and related information, consolidating everything into one centralized resource without manual effort. The result? Time savings and reduced errors.

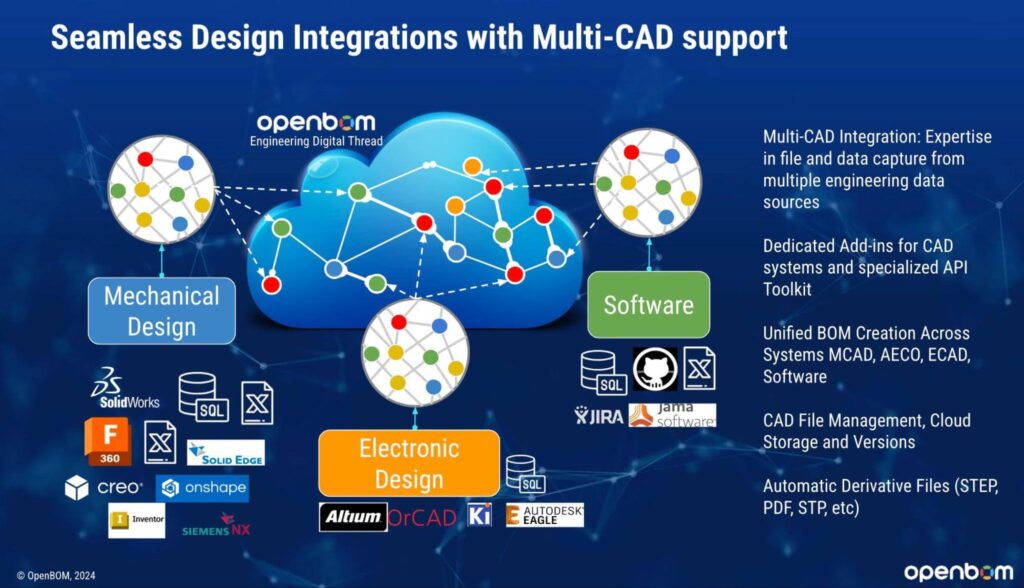

Consolidating Multi-Disciplinary Data into a Digital BOM

The Digital BOM serves as the foundation for uniting data from various disciplines—mechanical, electronics, and software—into a single, multi-level structure. Engineers can easily run queries, perform cost roll-ups, and assess readiness, ensuring that all components align perfectly before moving forward.

This consolidation simplifies collaboration and ensures every stakeholder has access to the full picture.

Inventory and Purchasing: Bridging PLM and ERP

One of OpenBOM’s standout features is its integration of inventory and procurement functions typically found in ERP systems. From managing inventory and vendor relationships to creating purchase orders (POs) and requests for quotes (RFQs), OpenBOM streamlines procurement planning. With gap analysis tools, users can effortlessly identify missing components and generate POs directly from the planning BOM, ensuring smooth and efficient supply chain operations.

Iterative Design Changes and Change Management

Innovation thrives on iteration, and OpenBOM fully supports iterative processes with robust change management and approval workflows. Teams can adjust designs, save new file versions, and regenerate updated BOMs. For instance, adding four new screws to a design is as simple as making the change, approving the Engineering Change Order (ECO), and creating a revised BOM and item structure. This iterative approach ensures flexibility without sacrificing control.

Watch the video of a Day in Life using OpenBOM

The following video covers the day-in-life scenario. Check this out.

Conclusion: A Unique Solution for Modern Product Development

OpenBOM stands apart by combining functionalities traditionally scattered across PDM, PLM, and ERP systems into a single, cohesive platform. While its PDM and PLM capabilities meet industry standards, its ERP-like features, such as inventory control and PO generation, create a unique value proposition.

By blending file-based and item-based data management, OpenBOM delivers an innovative service tailored to the needs of engineering teams and small to midsize manufacturing companies. It empowers users to manage their product development processes with unprecedented efficiency and agility.

Through this “Day in the Life” video, we invite you to see OpenBOM in action and discover how it can transform the way you work. Whether you’re an engineer designing the next breakthrough product, a manager overseeing approvals, or a procurement specialist ensuring smooth supply chain operations, OpenBOM is here to support your journey toward excellence in manufacturing.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.