At OpenBOM, we continuously strive to enhance the way engineers and manufacturers manage product data. A core part of our mission is to embed powerful tools directly into CAD applications and connect key pieces of information seamlessly to improve efficiency and collaboration.

Today, we are excited to preview two major enhancements to OpenBOM’s Design Projects functionality:

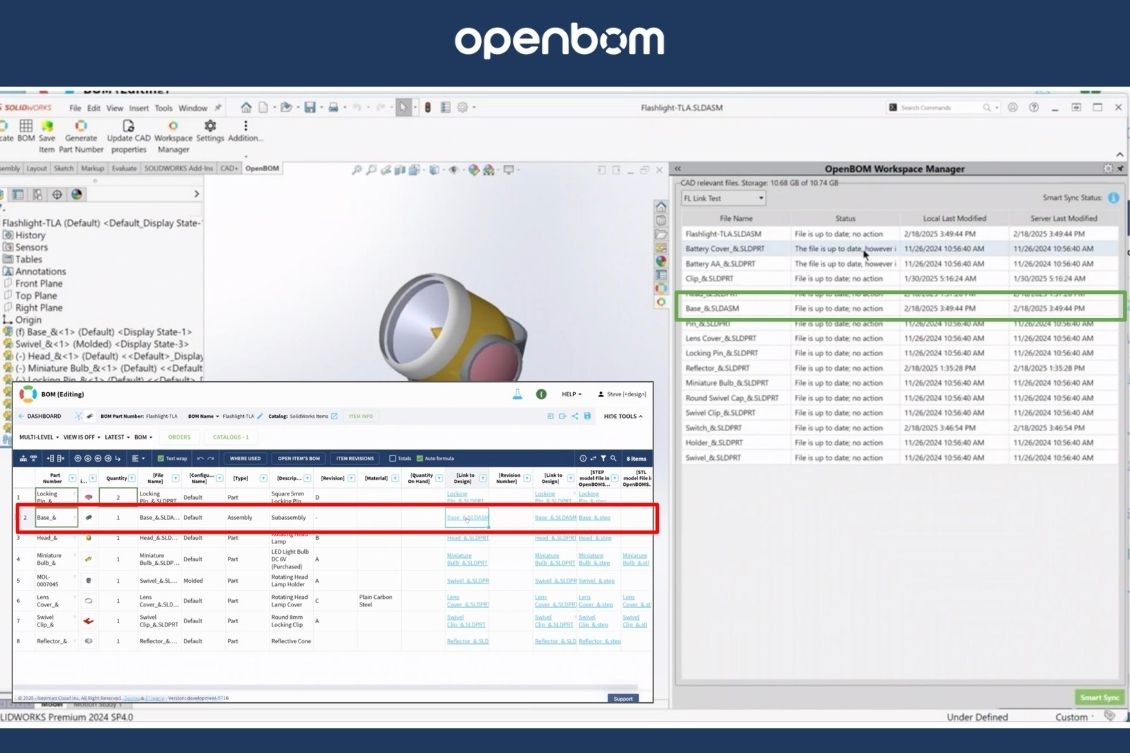

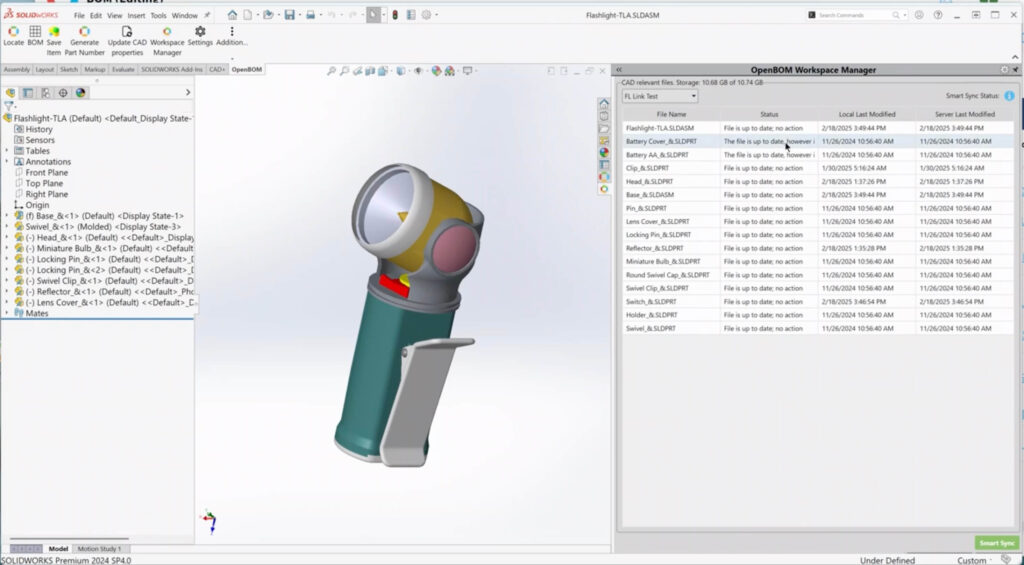

- Embedded Workspace Manager – Now available directly within SolidWorks, eliminating the need to switch between applications.

- Automatic Connected Items – A new capability that automatically links BOM items to design files, bridging the gap between “as-designed” and “as-engineered” data.

These updates mark a significant step in improving the user experience and ensuring that product data remains well-connected throughout the design and manufacturing process.

Embedded Workspace Manager: A More Seamless CAD Experience

Managing product data should be intuitive, not disruptive. With the new Embedded Workspace Manager, SolidWorks users can now access and manage OpenBOM Design Projects directly from within the SolidWorks interface, without needing to jump between multiple windows.

This enhancement significantly improves workflow efficiency by allowing users to:

✅ Stay within their familiar CAD environment while managing Design Projects.

✅ Quickly access BOM and project details without leaving SolidWorks.

✅ Improve focus and reduce interruptions in the design process.

💡 Coming Soon: Support for additional CAD platforms!

Automatic Connected Items: A Smarter Link Between Design & Engineering

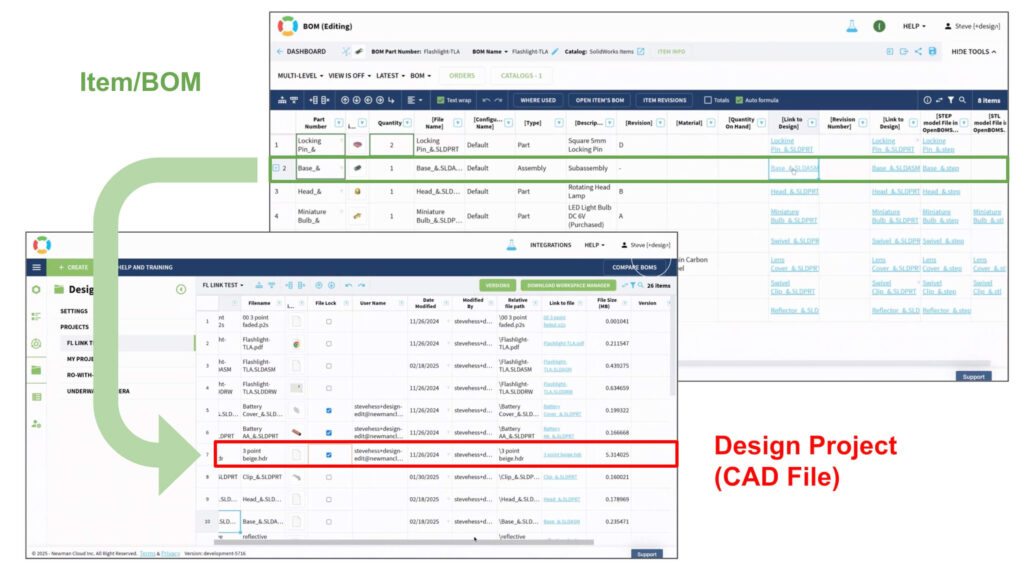

One of the persistent challenges in product lifecycle management is keeping design data connected to BOMs. Traditionally, “as-designed” and “as-engineered” data exist in separate silos, making it difficult to maintain traceability.

With OpenBOM’s new Automatic Connected Items feature, when you create a BOM from a SolidWorks assembly, OpenBOM now automatically links BOM items to their respective design files in Design Projects.

🔗 What This Means for You:

- The BOM and design files remain connected, ensuring easy access to critical information.

- Engineers can quickly trace where an item originated within the Design Project.

- It improves collaboration between design and manufacturing teams, reducing errors and miscommunication.

This new functionality closes the loop between design and engineering by ensuring that product data remains consistent and easily accessible.

Watch the video

Check the following video for an early preview of these functions.

Conclusion and What’s Next?

At OpenBOM, we believe that two fundamental aspects drive digital transformation in manufacturing:

1️⃣ User Experience – Tools should integrate seamlessly with existing workflows.

2️⃣ Connected Information – Data should be structured in a way that fosters collaboration and traceability.

The introduction of Embedded Workspace Manager and Automatic Connected Items represents another step forward in achieving this vision. By embedding OpenBOM deeper into CAD workflows and improving data connectivity, we are making it easier than ever for teams to manage product information effectively.

📺 Check the video demonstration, where we will showcase these new features in action and highlight how they can improve your workflow.

👉 Contact us today to learn more about how OpenBOM can help you streamline your product data management!

REGISTER FOR FREE and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.