When it comes to the development of data management solutions for industrial companies, manufacturing OEMs, engineers, suppliers, and contractors, we know that flexibility is a key element of successful architectures. Flexibility is a powerful concept that is appreciated by engineers and IT professionals. As much as out-of-the-box functionality is appreciated, the requirements for flexibility are always coming up with the same level of priority.

In the last five articles, I touched on OpenBOM’s Data Modeling best practices. I spoke about OpenBOM’s architecture which allows you to migrate from the beloved and hated Excel spreadsheets to the ready to be used data management solutions capable of managing product information and help you collaborate in your team, with contractors and suppliers.

If you missed my articles, please check them out here… Part 1, Part 2, Part 3, Part 4, Part 5.

To conclude this series of articles about data management, I want to share more information about OpenBOM’s Data Management architecture flexibility and ease of customization.

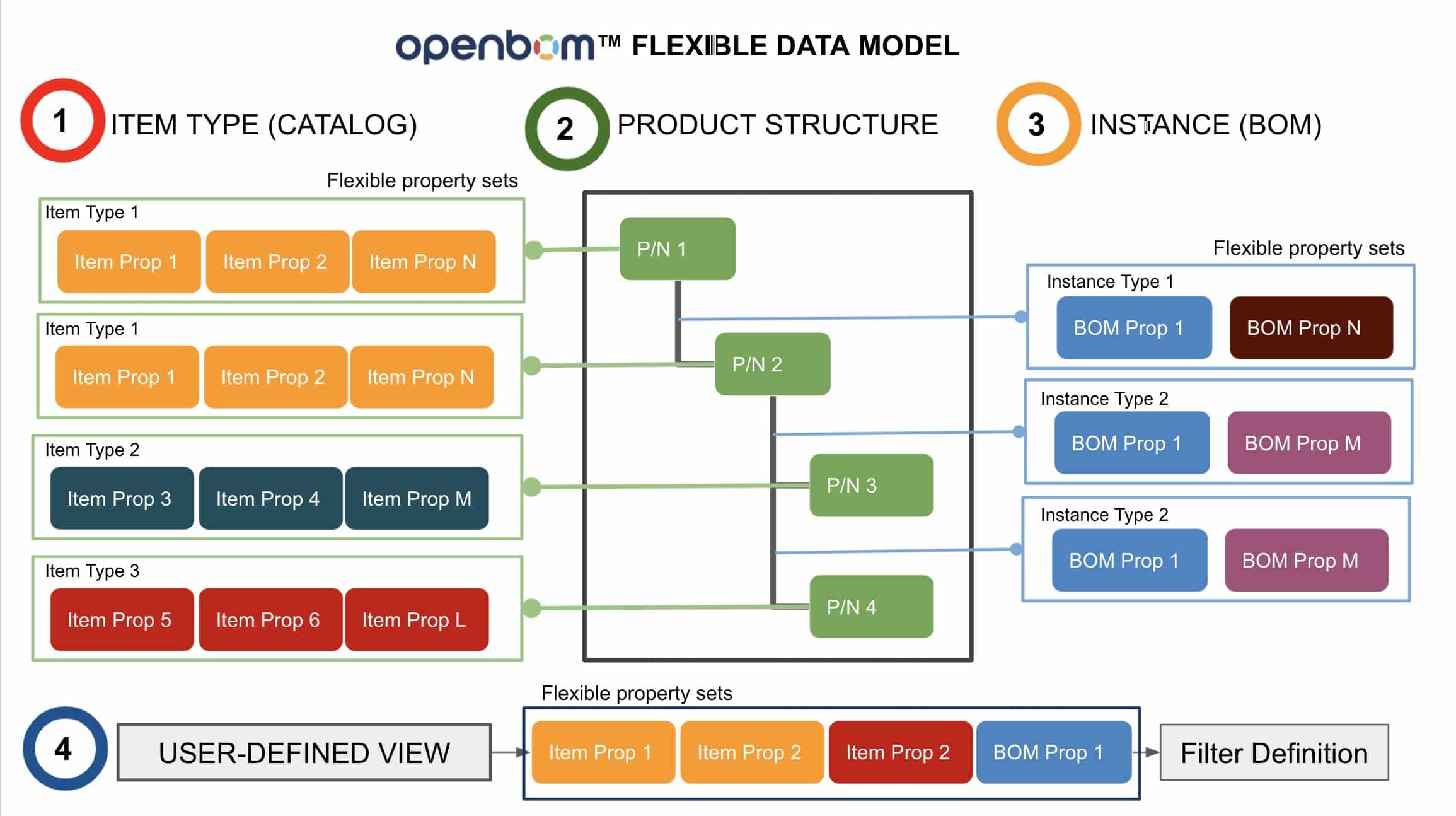

The following picture represents a schematic chart explaining the OpenBOM Data Model. You can already see familiar concepts, but I want to summarize what OpenBOM’s data management platform is capable of and most importantly how it can be flexibly adapted to any type of information that can be used by manufacturing and construction companies.Item Type (Catalog)

The model to manage items of different types is the core element of the OpenBOM information model. Each item type (catalog) can have a set of attributes (properties) to define the data. It includes structured properties (Text, Number, List, Reference, Data, etc.), which gives you a full descriptive semantic power to define the item in the way you need it.

Item Instance – BOM

When you use an item (reference) from a catalog, OpenBOM creates an instance of the item. There is full flexibility to define instance properties of any type. Also, different BOMs connected in the hierarchical relationship can have different sets of instance properties (Eg. Quantity for mechanical parts and Ref Designator for electronic assemblies). Instance properties combined with the capability to filter allows you to define multiple representations of the product structure.

Product Structure(s) – BOM

The product structure (hierarchical relationships) is built automatically by OpenBOM from Part Numbers. There is full flexibility to open the model and provide the information on how to automatically capture these relationships from external sources (Excel, Google Spreadsheets, CAD systems) as well as manually. You can define an unlimited number of structures and by using different part numbers you can define different Bill of Materials.

User-Defined View

While Item, Instance, and Product Structure define the data, User-Defined View is a lens to access this data. It provides a way to dynamically allocate a set of properties to be accessed (eg. displayed) in the catalog or BOM.

View is also completely flexible with the ability to define the virtual data sets filtered in both dimensions (set of properties, set of filters). Different views are used in OpenBOM to provide role-based access for different users as well as provide an easy way to contextualize the data access (eg. item type, version, engineering, purchasing, etc.)

Conclusion

The data is the foundation of any information solution. Once you’ve got the right data model, the sky’s the limit to build different business solutions. OpenBOM has a flexible and robust data model capable of keeping super complex data structures from multiple product development systems and customer environments.

In my next article, I will speak about the multi-tenant characteristics of OpenBOM’s flexible data model. In the meantime, register for OpenBOM for free online and get a free 14-day trial and explore how OpenBOM can help you and your business manage its very important data.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.