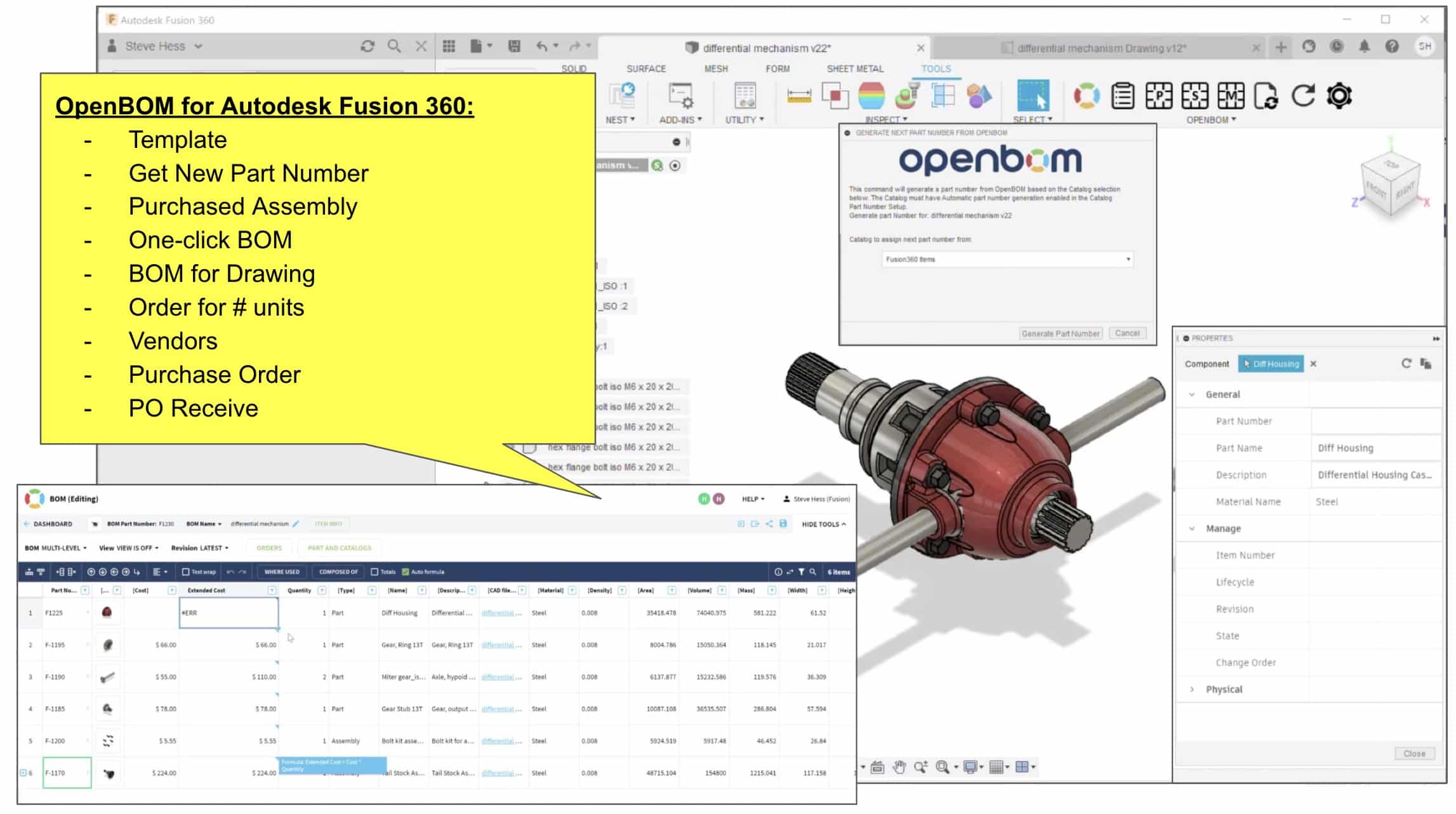

In this article, I’d like to give an overview of the recently introduced features in OpenBOM for Autodesk Fusion 360 and also provide a summary of best practices of how to use OpenBOM for Fusion 360.

A Video Demo

Let’s start with this video demo below which shows you the end-to-end process of how OpenBOM for Autodesk Fusion 360 makes your life easier and simpler by automating the process of BOM creation, cost calculation, procurement planning, inventory management, and ordering.

Make sure to keep reading as I will be giving you more examples of the process and setup below.

Setup and configuration

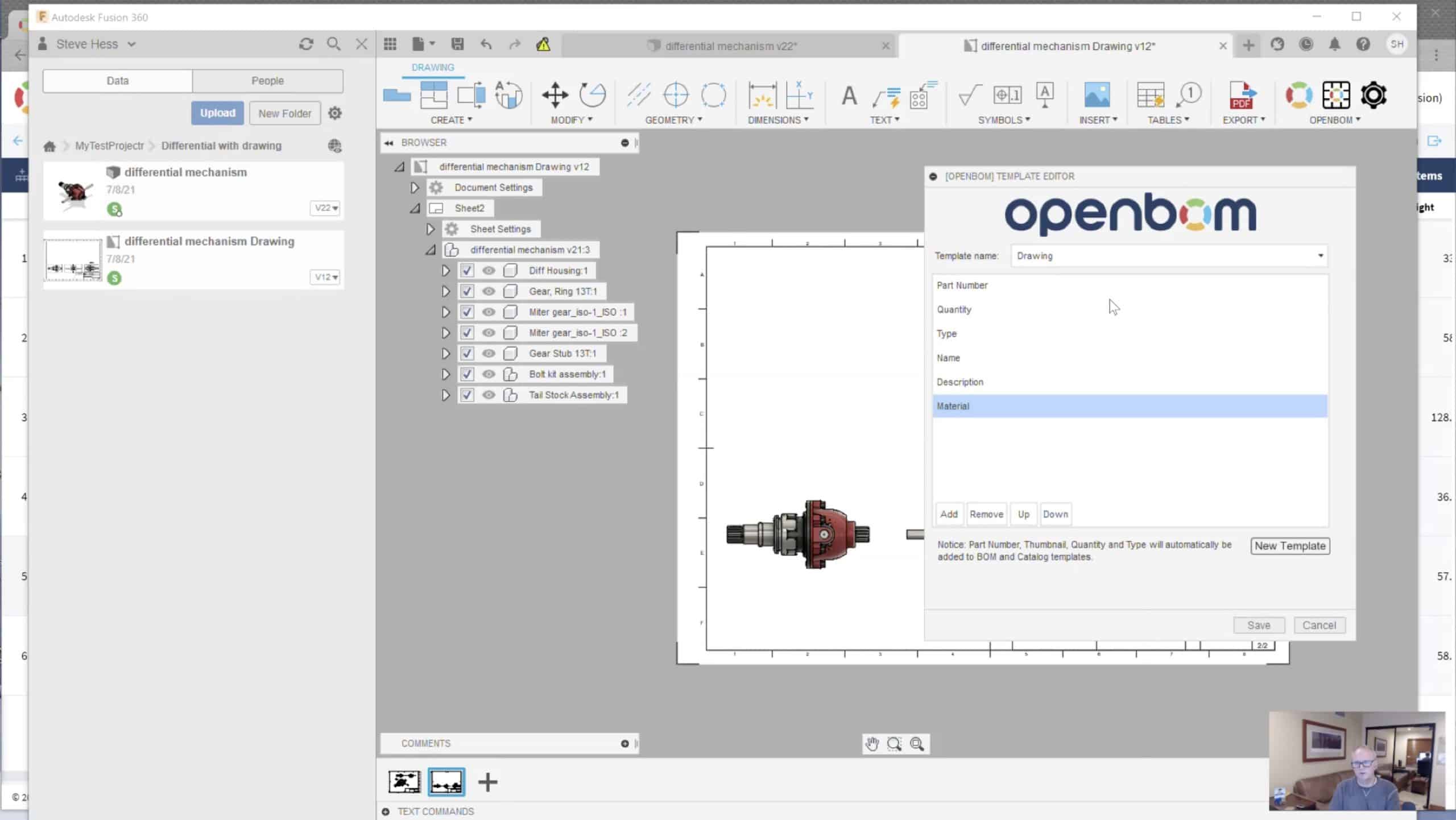

OpenBOM for Autodesk Fusion 360 comes installed in the toolbar section of Fusion 360. Be sure you are installed and you don’t have any pending updates there. Pending updates can make some of the recent features and bug fixes not available for you. Once you set this up be sure you have configured templates and other parameters if needed.

Assembly Management Features

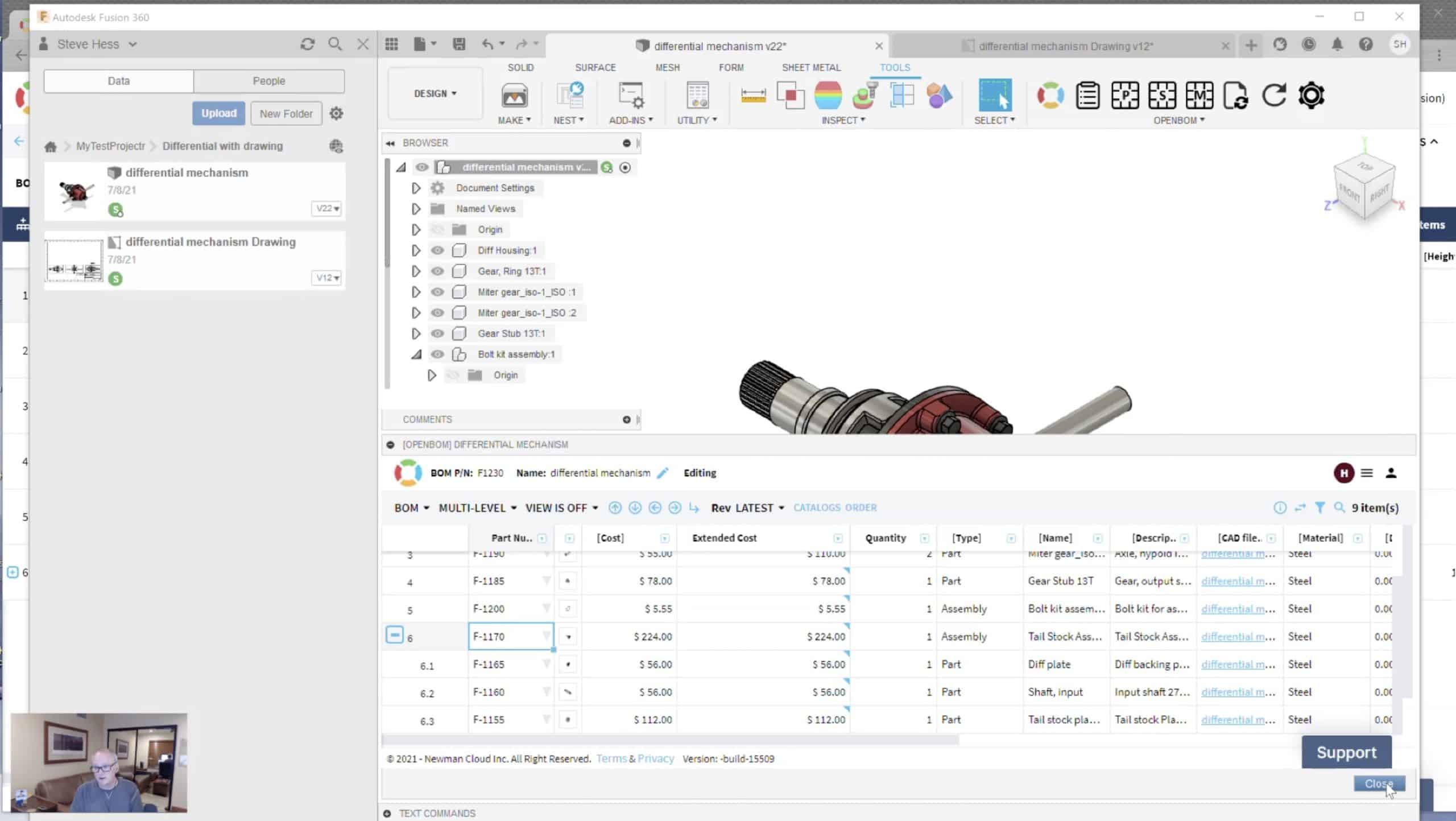

Fusion360 doesn’t have a traditional schema of assemblies/components (parts) like most other systems do. Fusion 360 is much more flexible and operates with bodies and components (design). You can keep an entire design in a single file, but also can separate it.

Keep in mind, OpenBOM will capture components and ignore bodies. Also, keep in mind that OpenBOM will capture components hierarchy as is, so it is a good idea to keep components hierarchy clean without any additional “levels” that will turn into separate BOMs and sub-level BOMs when the data is exported from the Fusion 360.

OpenBOM creates assembly (BOM) from the top design when you run it in Fusion 360 and automatically captures all data and creates items in Fusion 360 catalog database. Also, OpenBOM creates a multi-level product structure (recommended) as a hierarchy of BOMs.Purchased Assembly

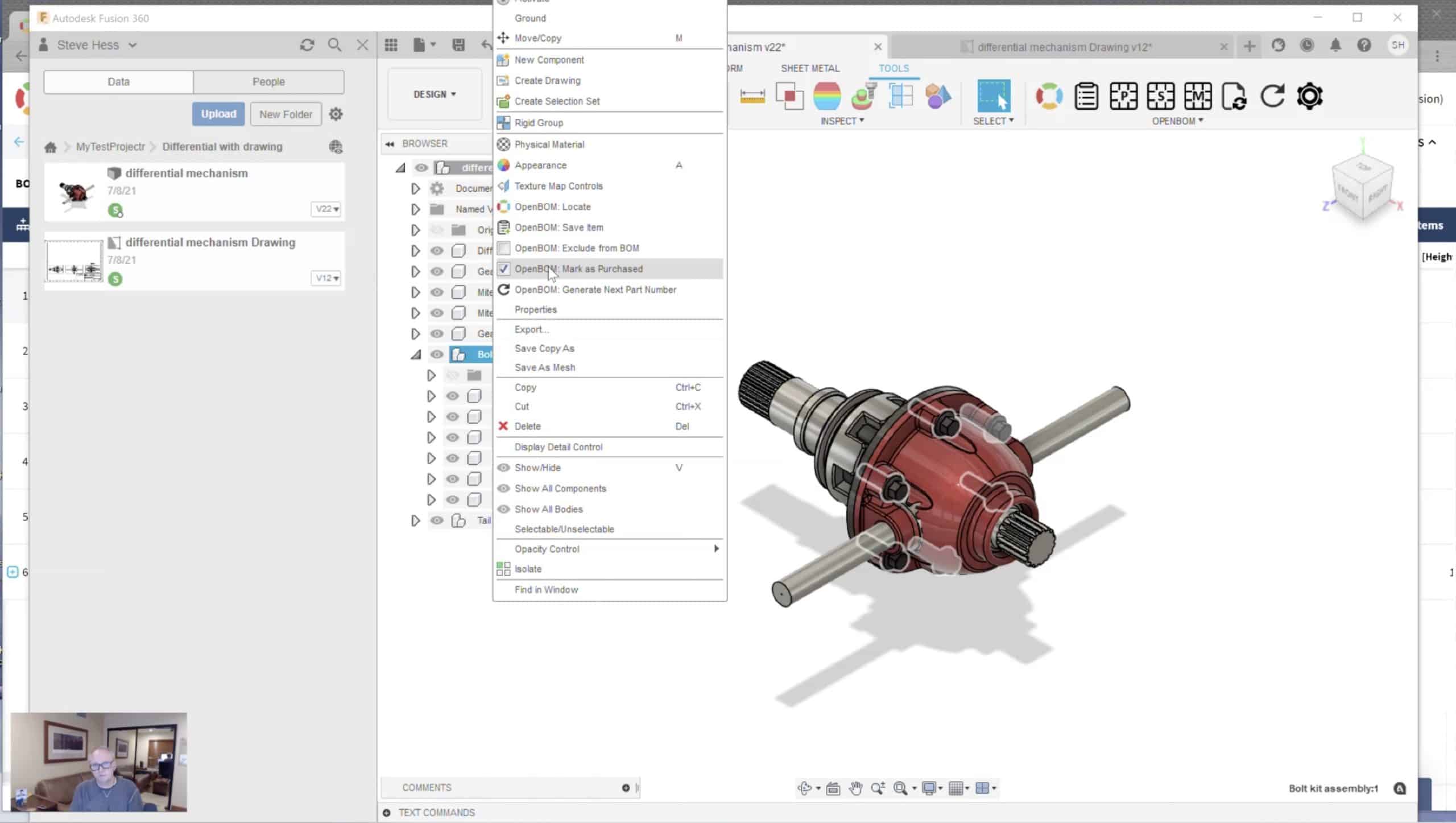

A super useful and powerful feature, helps you to define some of the assemblies you create as “purchased”, which means OpenBOM won’t get any sub-level from them even if the data does exist in Fusion 360.

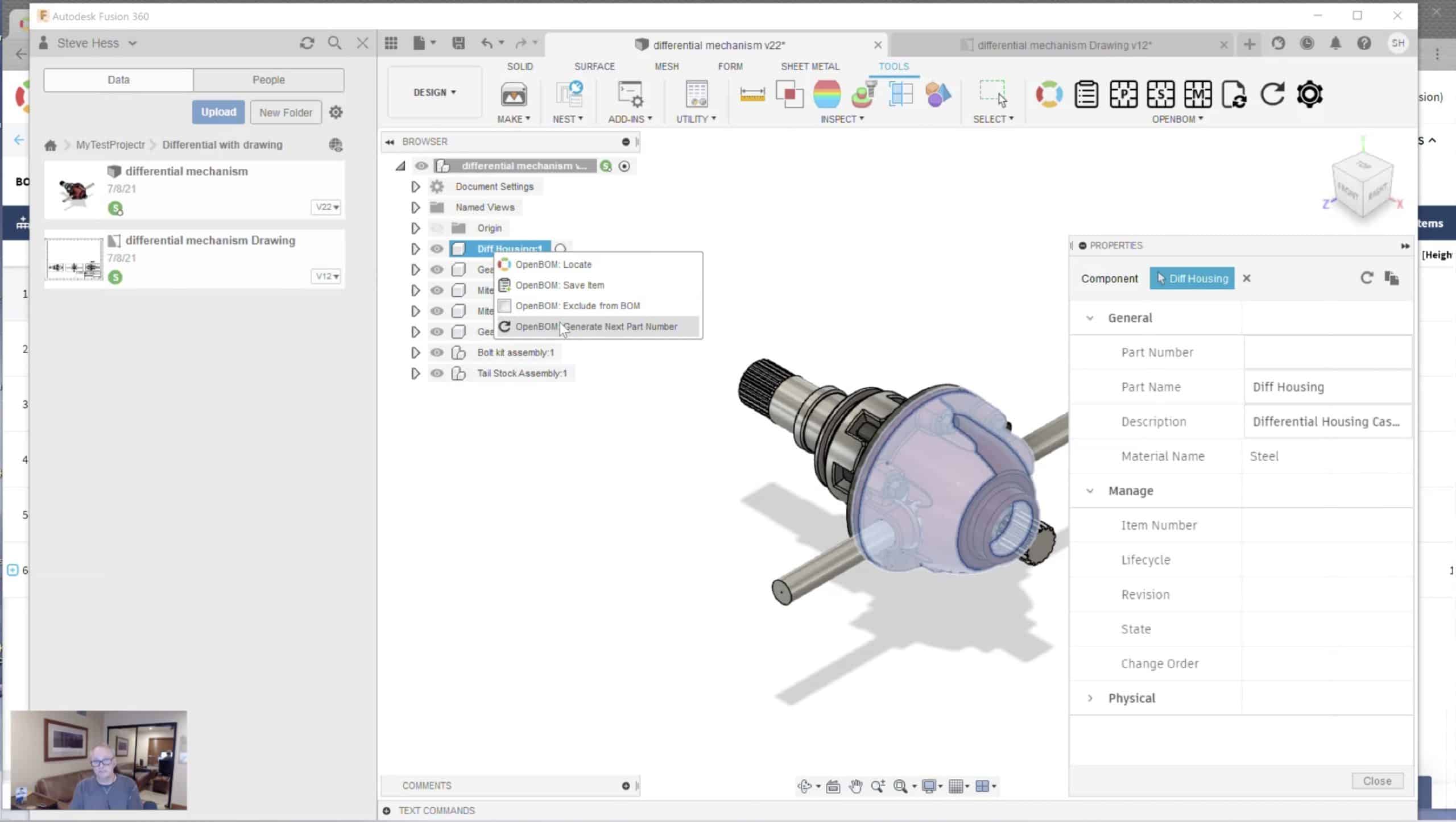

Exclude from BOM

Another useful feature allows you to exclude some of the components. If you select one of the components “excluded” the component and all sub-levels will be excluded.

Part Number Management

OpenBOM captures the information from Fusion 360 automatically based on the setting of the templates, but few basic values are always coming in – Name and Part Number. OpenBOM uses Part Number as a unique identifier for any item and if the Part Number exists, the Name will become a default Part Number.

Get Part Number

This is a super useful feature allowing you to get a reserved Part Number from the OpenBOM catalog. OpenBOM allows you to manage part numbers and Get Part Number connects components with the Part Numbers planned in OpenBOM.Multi-Level BOM

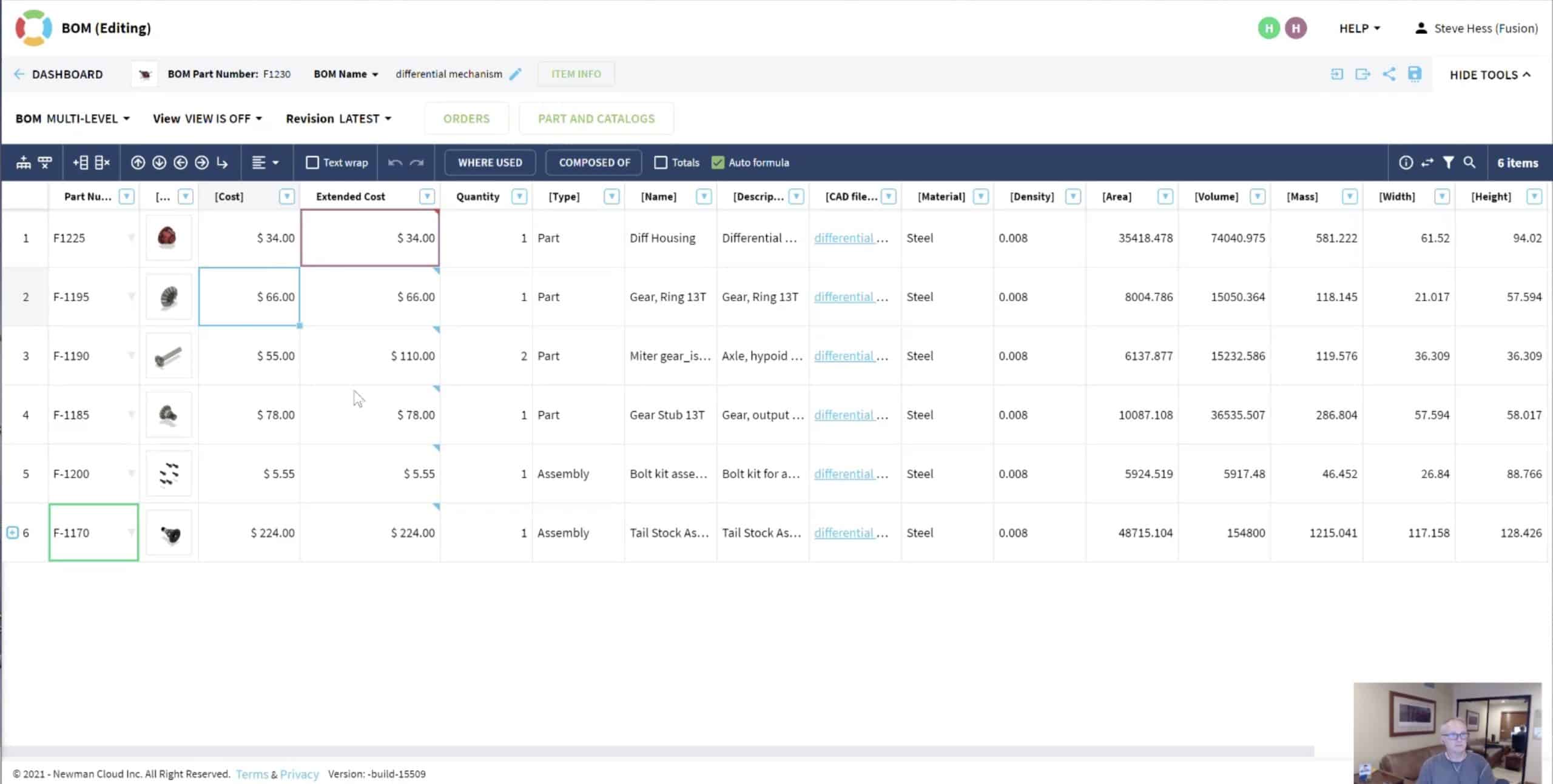

Creating a default multi-level BOM is always recommended. This product structure can be effectively used for many operations -calculations of cost, quantity rollup (flattened BOM), and many others.

Cost Calculation

Entering costs in the catalog and using formulas to roll up costs for the assembly is one of the most useful functions. Once the formula is set, OpenBOM will automatically roll up the cost between levels and calculate inventory cost and other business functions.

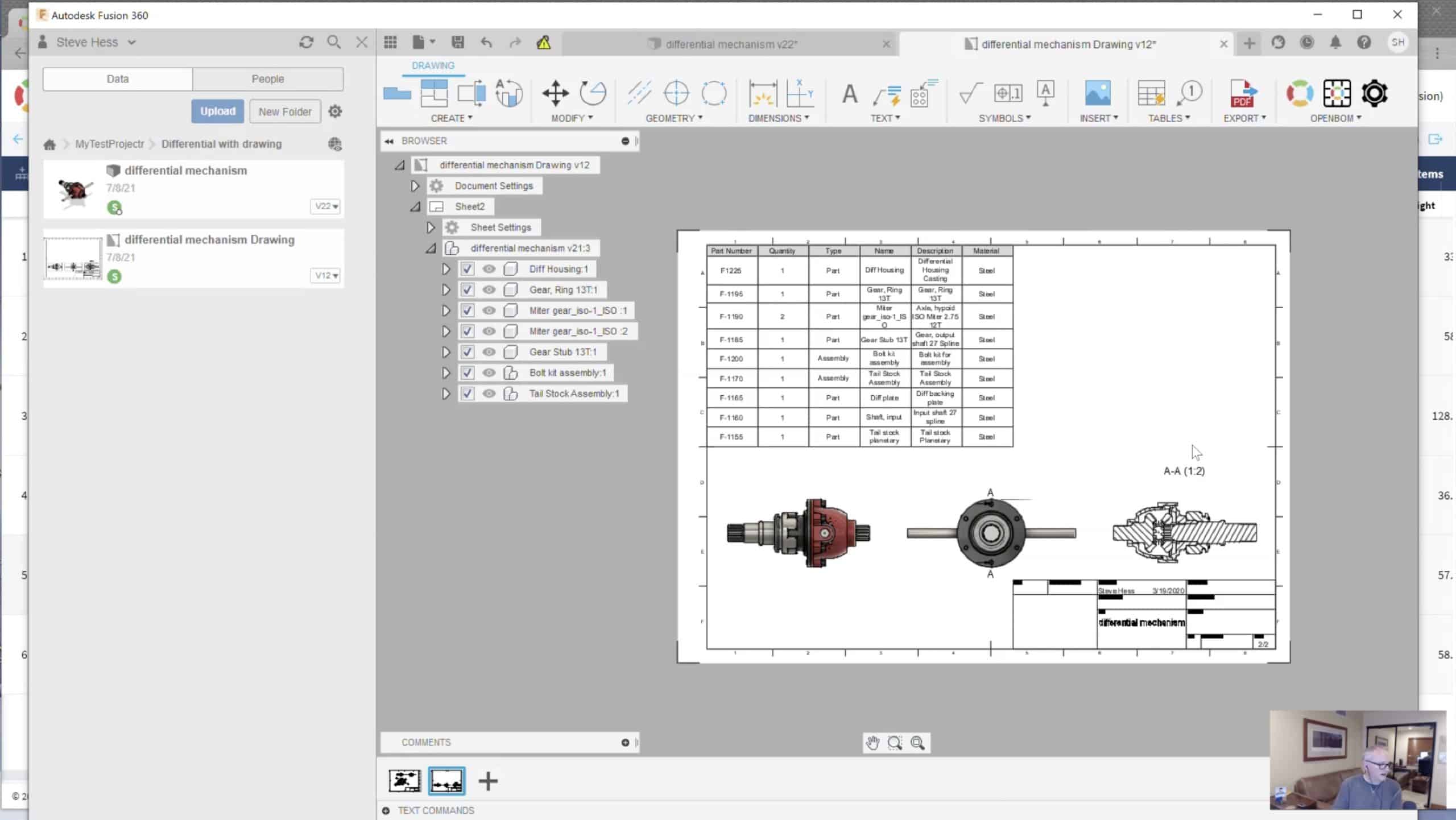

Part List

This function is a simple way to create a total list of all parts with a quantity that usually can be easily used for drawings. The data in Part List will be identical to Flattened BOM, but it can be easily customized and imported into Fusion 360 drawings.

Drawing BOM

Once you get a multi-level BOM or part list you can then insert it into Fusion 360 drawings. Keep in mind that a part list is useful in making a cross assembly list of parts in the Fusion360. But if you insert a multi-level BOM, only the first level will be imported to the drawing (a multi-level option is coming).

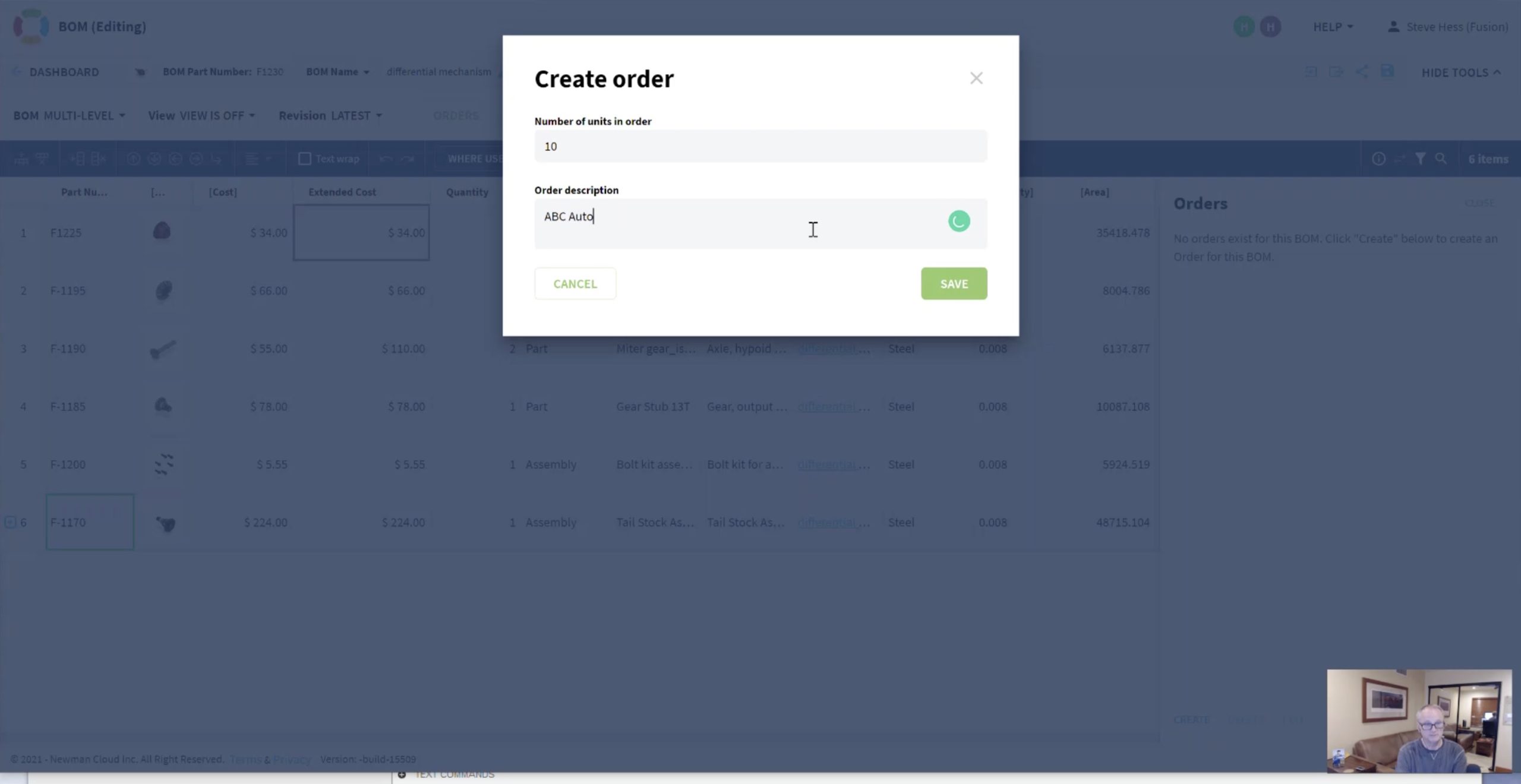

Order Management and Purchase Orders

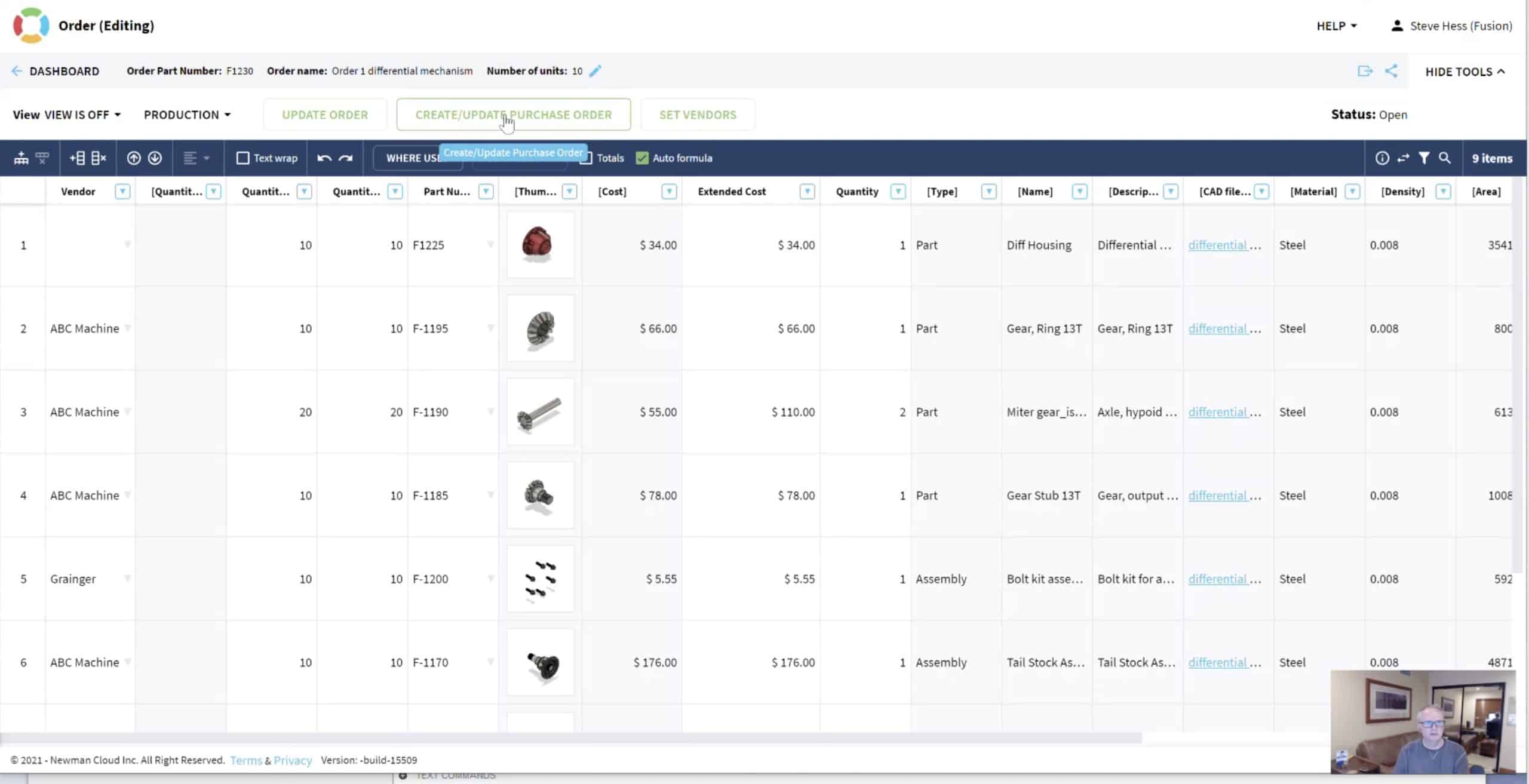

OpenBOM production planning mechanism can be used to manage vendors and create a batch order (for example for 10 units) to count all parts and assemblies that need to be ordered or produced.

Create an Order for a number of units

Here is the command to create an order from the BOM. The function is the simplest way to make a plan and it is available to everyone (from professional users). An alternative to create orders directly from the catalog is available too. Combined with advanced inventory control, it is available in OpenBOM’s company sub.

Vendor Management & Setting Vendors

Assigning a vendor to each item is easier to make in the catalog upfront. But you can also adjust each specific vendor already in the Order before generating POs.

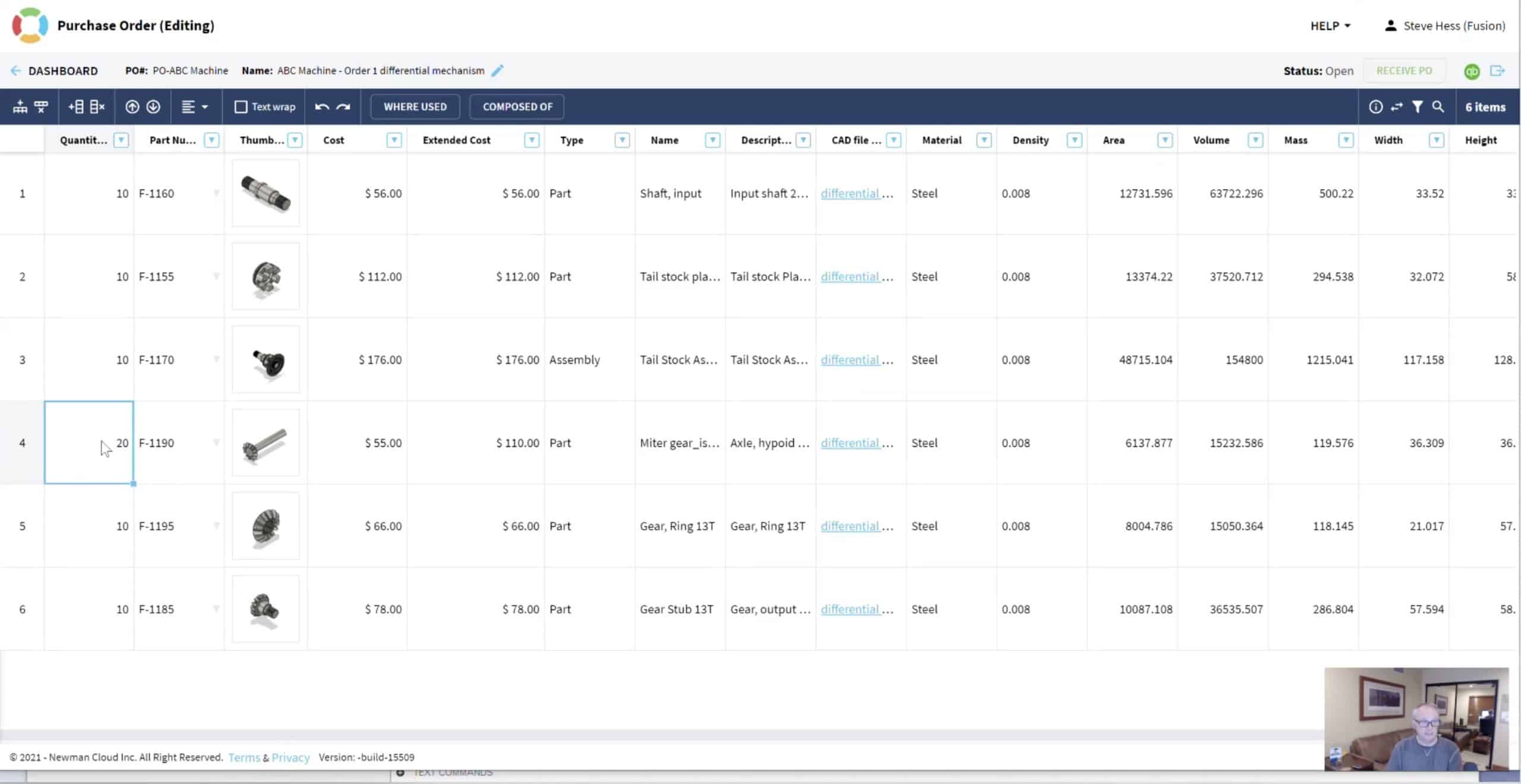

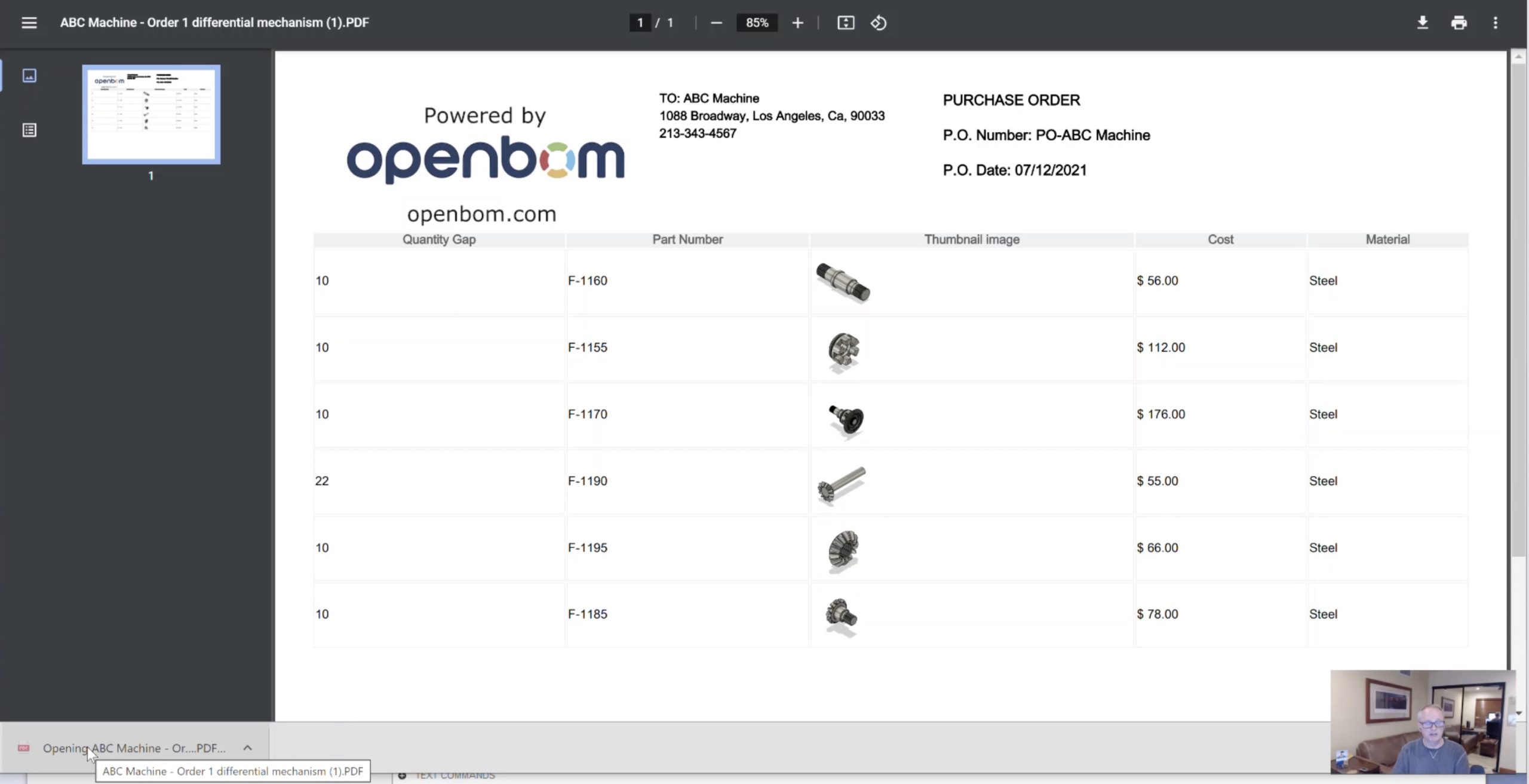

PO Management

These functions allow you to generate PO from the order (based on vendor assignments), to keep them in sync with everything that happens in the BOM, and send it to vendors (eg. via online integration such as example Quickbooks or export (Excel / PDF).

A second important function is the Receive PO functionality, which allows you to bring data from Excel back to OpenBOM and update the values of Quantity on Hand.

Conclusion

OpenBOM for Fusion 360 is your one-stop solution for working with BOMs in Fusion360 and performing ordering and vendor management. It brings advanced BOM management and planning functionality to all Fusion 360 users. If you have any questions, let us know.

In the meantime, make sure to register for OpenBOM’s FREE 14-day trial and check it out for yourself.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.