I’m continuing to share more information and sneak peek into the upcoming features and improvements of OpenBOM for Autodesk Fusion, which are set to be unveiled later in August 2024. These enhancements are designed to streamline your workflow, making it easier than ever to manage your Bills of Materials (BOM) and related data directly within Autodesk Fusion.

The new capabilities we’re rolling out include:

- Quick Start (Simplified BOM Creation)

- PDF for Drawings Support

- DXF for Sheet Metal

- Item Classification Support

- Fusion Configuration Support

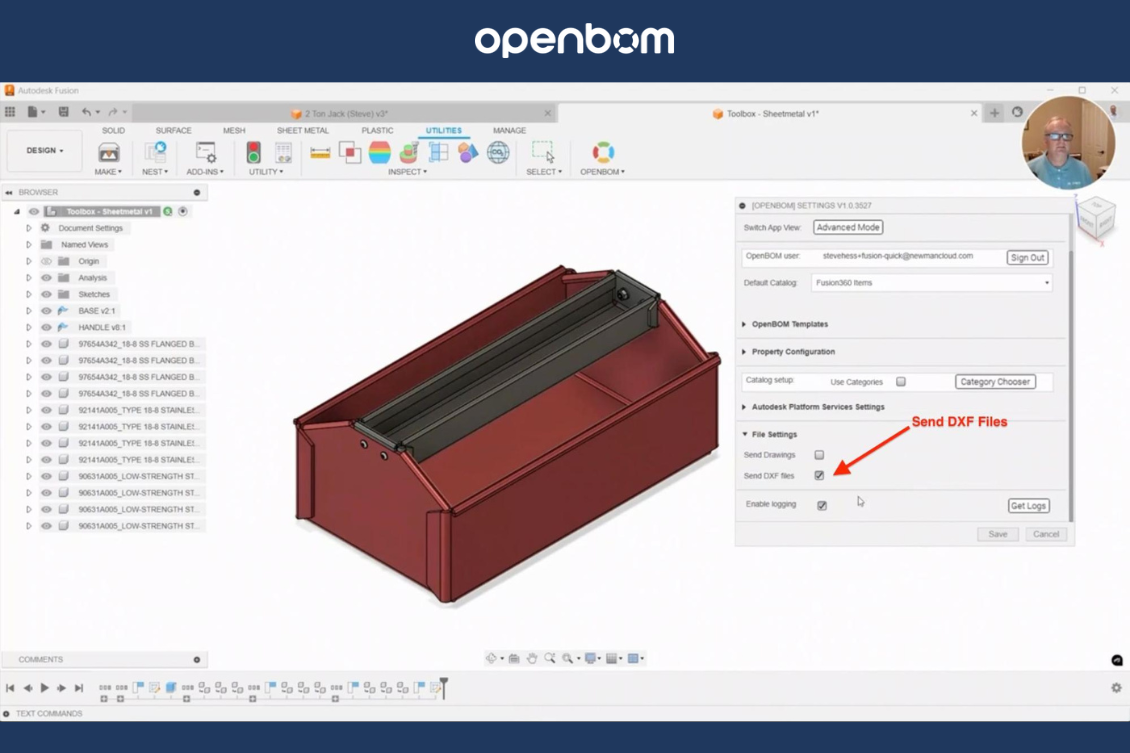

In our ongoing effort to enhance your experience with OpenBOM for Autodesk Fusion, we’re excited to introduce a powerful new feature—DXF generation for sheet metal parts. This addition is designed to simplify and streamline your sheet metal fabrication process, making it easier than ever to manage cost estimation and procurement. A new “DXF for Sheet Metal” function allows users to produce a useful and important set of information when designing sheet metal parts.

Streamline Your Fabrication Process

When working with sheet metal, accuracy and efficiency are very important. The DXF (Drawing Exchange Format) is a critical file type that facilitates the precise cutting and fabrication of sheet metal parts. Typically, every sheet metal part requires a DXF file that is set to production or supplier to make the part cost assessment and manufacturing. With OpenBOM’s latest feature, you can now automate the generation of DXF flat patterns directly from your Autodesk Fusion designs.

This automation removes the manual steps typically involved in DXF creation, reducing the risk of errors and saving valuable time. By integrating this function into your workflow, you ensure that your flat patterns are always accurate, up-to-date, and ready for manufacturing.

Seamless Integration into Your Bill of Materials

But the advantages don’t stop at automation. OpenBOM goes a step further by automatically adding the dimensions of these sheet metal flat parts into your Bill of Materials (BOM). This ensures that all necessary information is captured in a single location (Item catalog), improving traceability and simplifying the handover process to your procurement and manufacturing teams.

With the dimensions readily available in your BOM, cost estimation becomes more straightforward, and procurement teams have all the data they need at their fingertips. This integration not only enhances efficiency but also promotes better communication across teams, ensuring that everyone is working with the most accurate and up-to-date information.

Video Preview

Check the video to learn more about DXF for Sheet metal function.

Conclusion

The introduction of DXF generation for sheet metal parts is a significant leap forward for engineers and manufacturers using OpenBOM for Autodesk Fusion. Whether you’re managing a small batch of parts or overseeing a large-scale production run, this feature will streamline your workflow and enhance the accuracy of your outputs.

Stay tuned for more updates as we continue to expand the capabilities of OpenBOM for Autodesk Fusion, providing you with the tools you need to succeed in today’s fast-paced manufacturing environment.

REGISTER FOR FREE and check out these and other capabilities of OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.