Unless you lived under the rock for the last several years, you’ve heard about Digital Transformation and Digital Thread. While we are all excited about the power of digital technologies, I often see companies are confused about these new things and have a hard time bridging between day to day operations and digital futures. In my article today, I’d like to help you to close the gap and wrap your head around how to approach Digital Thread and what role OpenBOM can play in your future digital business.

In my recent Beyond PLM article, I shared how companies are moving from BOM exchanges between siloed data to connected Digital Twins. How to make these connections and manage data in a reliable robust form?

Every engineering, product development, or manufacturing organization should have their processes organized. While this is an obvious thing, it is often easy to say rather than do. On a high level, you need to have data about parts, products, and changes. Who did what, when, and how things are depending on other people, products, and processes. It is important for new product development and even more important when you’re pulling your existing product for re-worked.

A concept of a digital thread, in a nutshell, will allow to engineering and production team to record the process from the early beginning to the stages when the product is sold and maintained. It allows you to collect all the needed documents and connect them together. It allows you to have all contextual information in a single place or have relevant links.

The idea of a digital thread is to have information connected, which doesn’t mean that the data must be stored in a single system. There is nothing wrong with that, but in the reality of modern manufacturing world, to have everything collected in a single place can be an overarching goal that will never be accomplished, while it will drain your time and resources.

Here are some unique OpenBOM features that can help you establish a digital thread of valuable information today with a minimum effort.

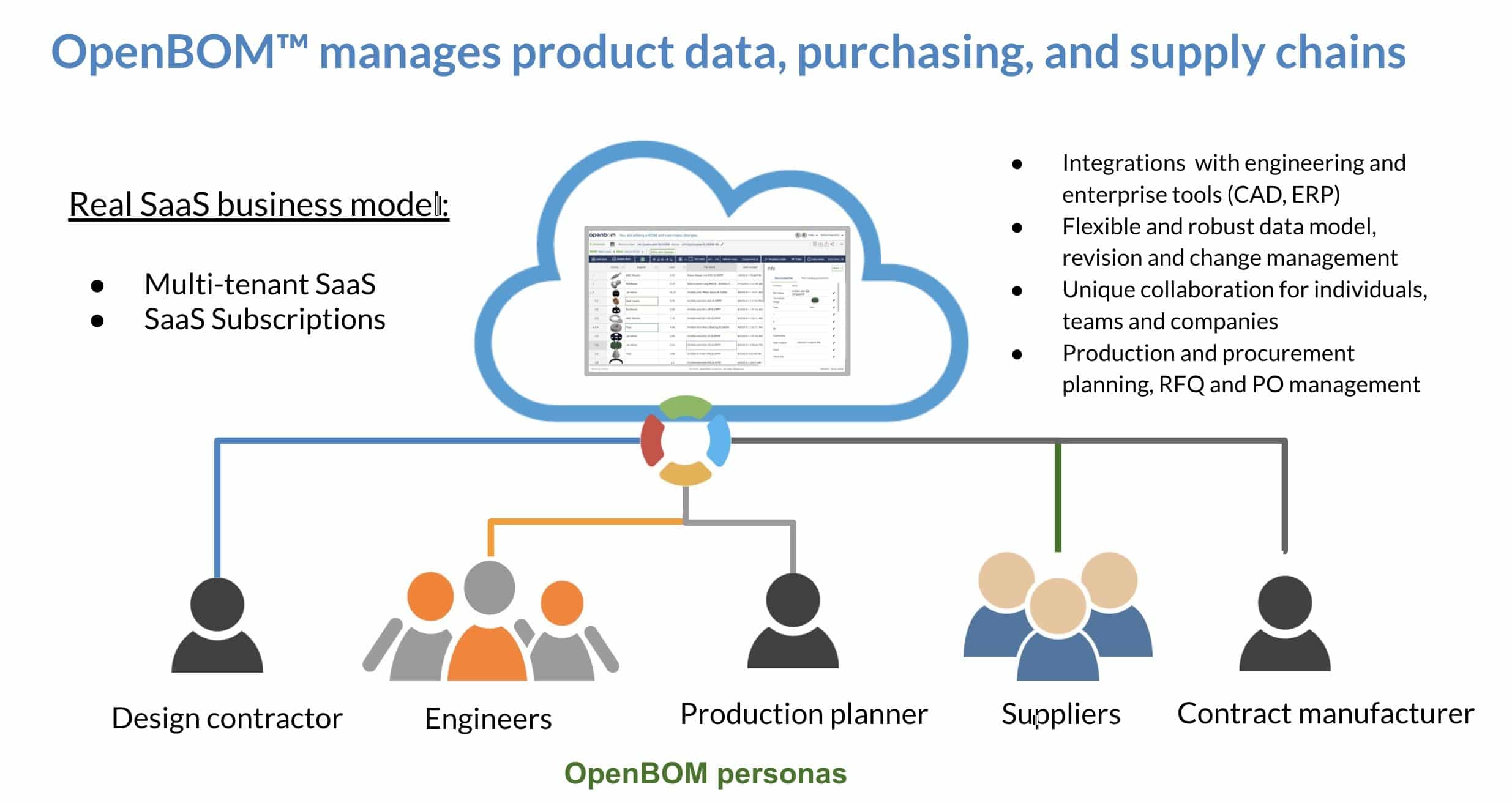

Real Multi-tenant SaaS

Any company or individual can create an online account in OpenBOM at any time. The data will be secured online and can be shared with the right access permissions with anyone. Engineering and production data in one account (manufacturing company) can be linked to customer data and real products in the field collecting customer data (customer) and provide real-time data links between both environments.

Flexible Data Model

OpenBOM data model can be easily enhanced in real-time without any specific development efforts and administration. Think about Excel-like flexibility with a huge amount of PLM, BOM, and engineering data steroids. So, all your data will be collected and managed.

Automatic history of changes and revision support

OpenBOM automatically collects all changes you do in the data. No special effort is needed. You always have a traceable record of changes. In addition to that, OpenBOM revisions allow you to preserve immutable snapshots of data and produce reports about changes.

Learn more about what OpenBOM can do for you by navigating the OpenBOM Training Library.

Conclusion

I predict the Digital Thread will be a dominant concept in engineering and manufacturing space connecting people, data, and processes. OpenBOM is a digital network platform that manages product data and connects manufacturers and their supply chain networks. OpenBOM infrastructure is an easy way to step into your digital future by pulling information from multiple Excel files and different data sources, recording all changes, and sharing data with your team, suppliers, and contractors.

OpenBOM has partners that can help you in your digital transformation journey. Check what OpenBOM can do for you today, by starting a free free 14-days trial using a one-click registration.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.