Engineers and manufacturing professionals are looking for efficient ways to manage information. One of the most essential and critical elements of the production process is to have various pieces of information coming together at the same time connected and transferred between multiple people in the organization without spending too much time creating the information.

OpenBOM For Onshape – Information Flow

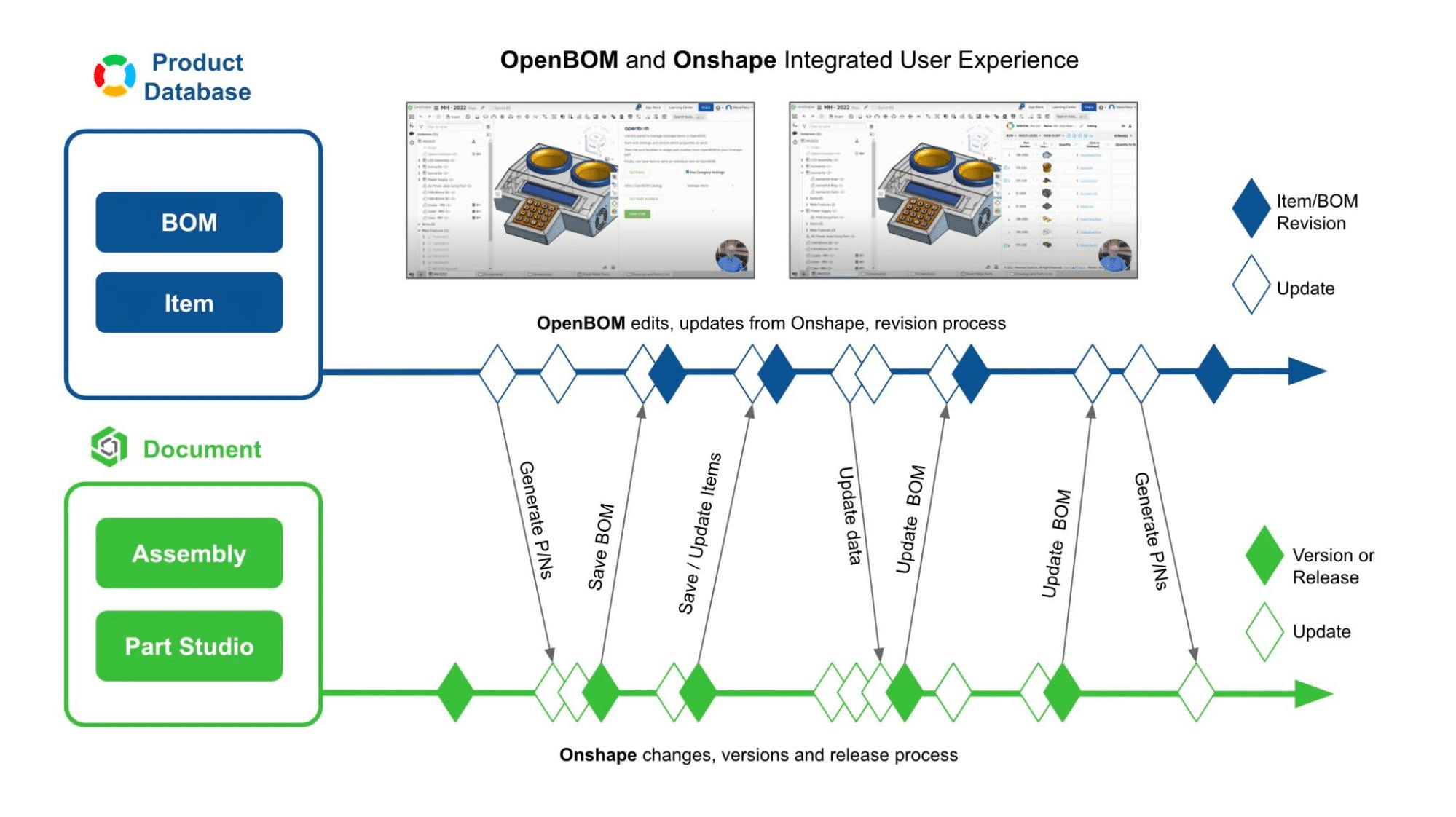

OpenBOM provides seamless integration with Onshape enabling it to perform a critical set of BOM management activities to form a complex product definition. It includes:

- Create a Bill of Materials automatically

- Pull all relevant data from the parts and assemblies (based on the data mapping)

- Add all necessary items that are not described in Onshape to the BOMs

- Combine this data to create a comprehensive Bill of Materials

- Release it to product for procurement and planning.

The following picture can give you an idea of how OpenBOM is capable of interplaying with Onshape to exchange information and organize BOM management activities.

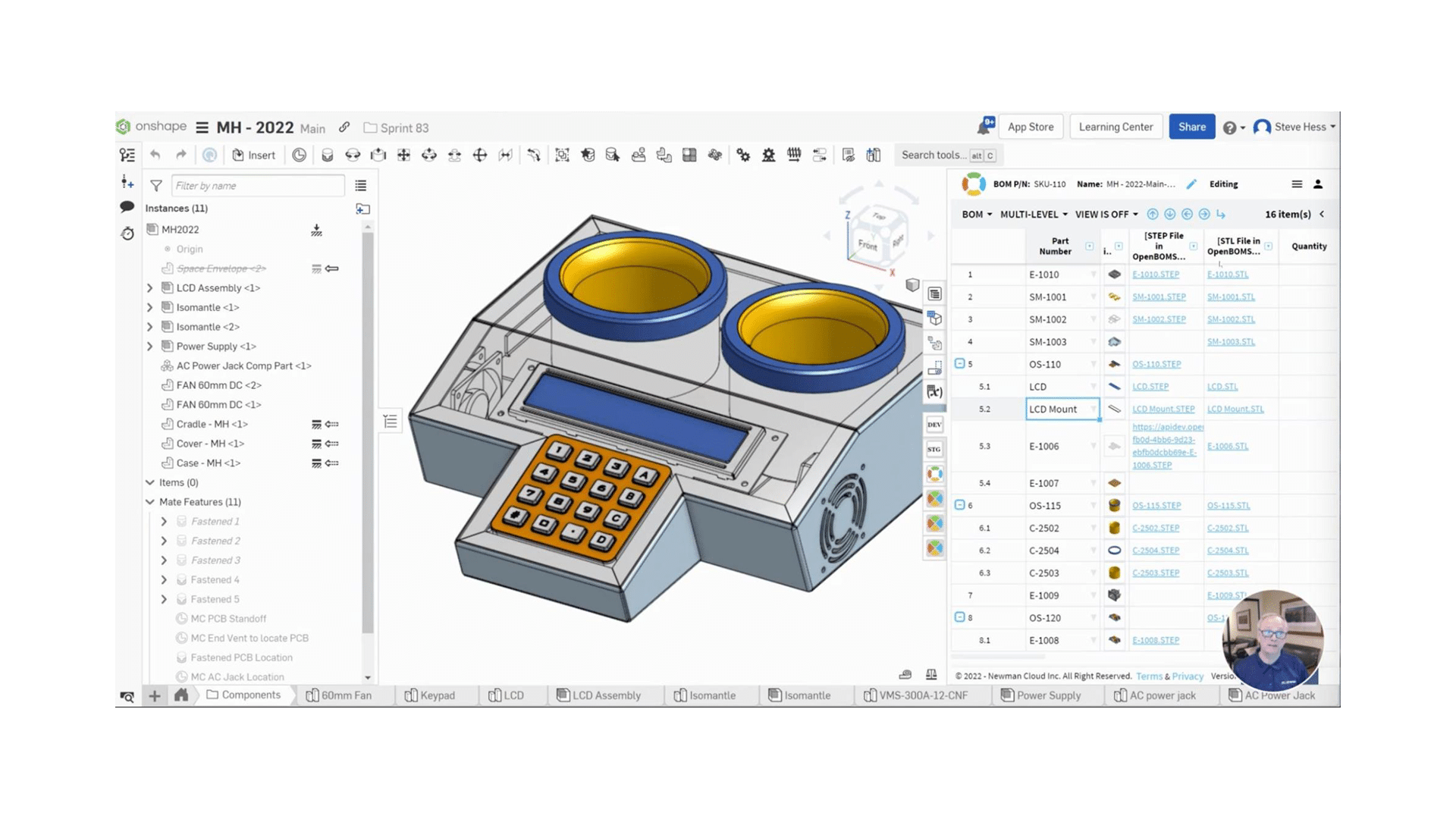

Derivative Files – PDF, STEP, STL…

A complete product definition (and BOM) usually include additional files that are derivatives from the native CAD documents. Examples of these files are STEPs, PDFs, and sometimes STL files. Manufacturing companies typically create these files for 3D data and drawings to include this information in the release packages to be transferred to product planning, procurement, and production.

Creating these files is a tedious process that requires time to export files, collect them together, attach them to BOMs and package it into a zip file to send to CMs or production. At OpenBOM we are allowed engineers working with different CAD software to automate the process of derivative file generation and make it simple and easy.

I’m super excited to preview a function to automatically create STEP and STL files for Onshape Parts and Assemblies. The files are created automatically and attached to the Bill of Materials and Items in the catalogs. Once it is done, you can extract files using an export function to a zip file or share it in real-time with everyone else using the OpenBOM share function.

Watch the video to see how it will work.

Note, that we are also planning to support automatic PDF creation for Onshape drawings.

Conclusion

A seamless information handover is one of the most important elements of improving the efficiency of product development and manufacturing processes. OpenBOM allows you to automate the process of data and files handover between systems and make derivative file creation for an entire assembly easy with a simple click of the button. The feature will soon be available to all OpenBOM customers. Stay tuned…

REGISTER FOR FREE and start a 14-day trial to check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.