How to create BOM for Solidworks? Sounds like a simple question? If you’re Solidworks user, you probably did it many times by creating Excel export. It is simple, but it is a pandora box of spreadsheet BOM hell. A simple process of export creates tons of questions:

1- How to share the file with people who need it the most (production planners and purchasing manager). How to share the right file?

2- How to update it once it changed (on both sides – Solidworks design and purchasing cost, supplier information).

3- Should we update data back from Excel to Solidworks?

These are only a few questions, but there are many others.

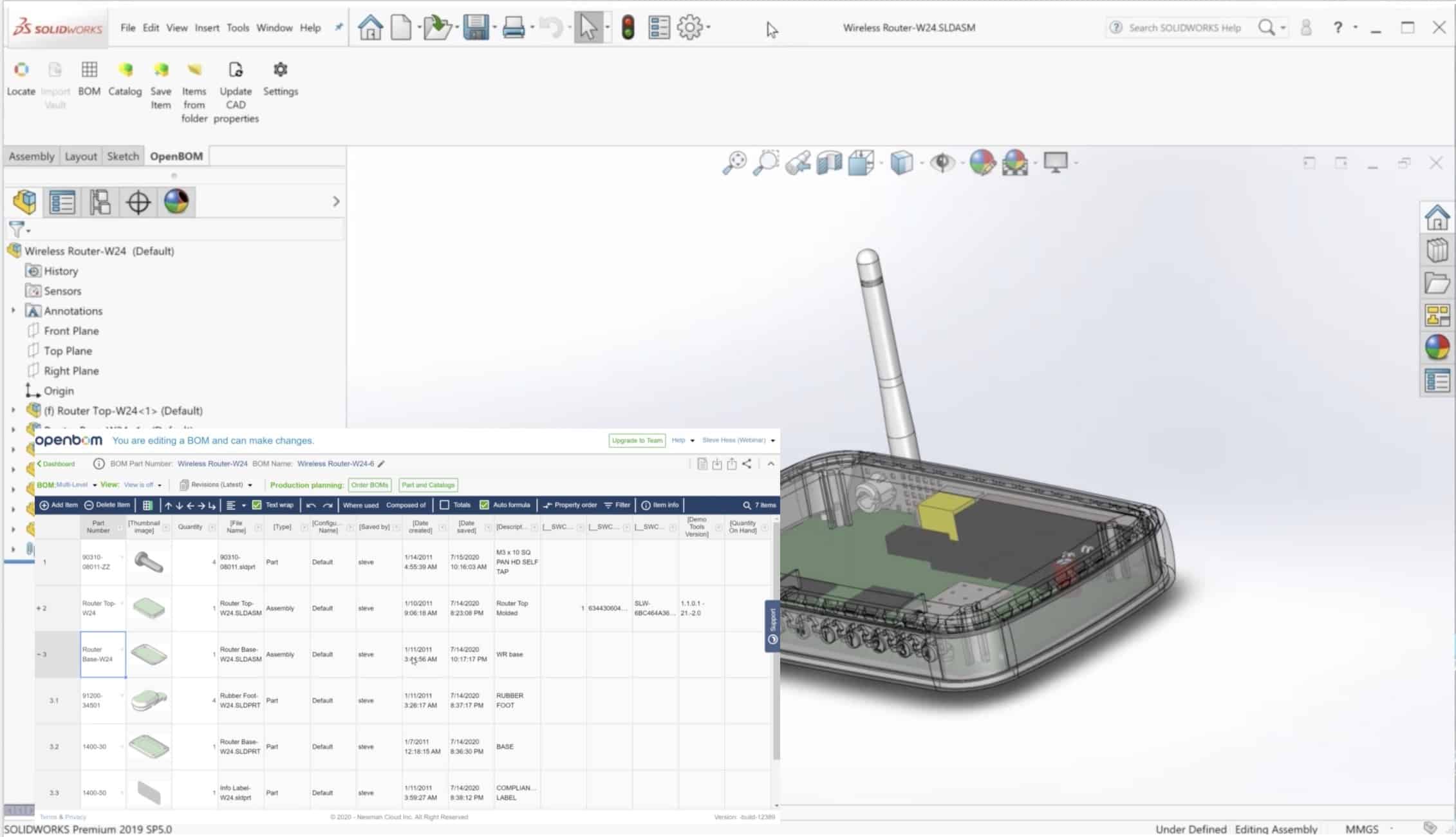

At OpenBOM, we’ve been working hard to provide a seamless and easy way to establish a single version of truth for product BOM information and make it fully integrated with Solidworks.

In this webinar, we demonstrate how to manage the process of BOM creation from Solidworks. This is the first webinar. More to come. Check this out.

Also, check out the slides used during this webinar

OpenBOM Webinar #24 – Mastering Solidworks BOMs from Oleg Shilovitsky

Conclusion

OpenBOM provides the seamless, yet configurable process of BOM management together with SOLIDWORKS. The data is connected and transparent. OpenBOM allows you to have bi-directional data sync as well as supports all internal rules and features of SOLIDWORKS such as Part Number, exclude from BOM, configurations, show/hide, and many others. Check the full list of webinars here.

Check our how OpenBOM helps thousands of users and manufacturing companies to streamline data management, processes, and escape the legacy of Excel spreadsheets.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.