With globalization here to stay, worldwide competition is a real and serious obstacle that most product development companies need to keep an eye on.

Globalization has made it so that what is new today may be obsolete tomorrow. Time pressure is another obstacle that is currently hurting companies in their race to deliver new products. When time is an issue, communication and organization usually break down which in turn affects the end product.

Enterprise Software Is The Bottleneck In New Product Development

To win this race of who has the latest and best product on the market, companies are creating new product development units that are feverishly working away at new prototypes that eventually will join their well-known and top-selling product line.

While it is a great idea, implementation is usually not that simple thanks to teams being forced to use old enterprise tools (Eg. ERP, PLM, etc.). These tools were deployed on-premise and implemented to support well-established business processes.

Nothing wrong here, but as some of my colleagues in the industry says, there is no better way to stop the product development process than by introducing enterprise software tools into this process.

In my article Spreadsheets vs PLM dilemma to manage BoM, Scott Miller CEO of Dragon Innovation and the man behind Rumba (iRobot) production development speaks about how enterprise tools can slow down the development process. My favorite quote in the video at 3:30

– “Nothing stops us faster than Windchill. PLM can put us in a dead stop when we are trying to get a product out”.

Companies Struggle To Find a Solution And Turn To… Excel.

Spreadsheets (or Excel) is the second-best software in everything. When it comes to finding a solution to run the product development process, manage BOM, organize information, and update the information, companies have no option but to turn to Excel.

Here is how one of OpenBOM’s customers, a Fortune 500 manufacturing company developing electronic consumer and industrial products, struggled to find a solution to the problem before the head of the design team turned to OpenBOM to help bring it all together.

“We just didn’t have processes in place to store non-CAD business information which was crucial to our product in our existing CAD / PDM system” says the lead engineer at the company. “So we put it in Excel. – and all the problems then flowed from that.”

“We had multiple places and Excel file copies which every member of the team must have access to. We couldn’t control access or maintain a master efficiently. As a result, everyone had to be an Excel VLookup expert or we would break this complicated table. The whole process was exhausting.”

As product development was ready to scale into higher volume manufacturing, this Excel-driven process was too fragile to share outside the core team and to collaborate with.

Read more about how this Fortune 500 company solved the problem using OpenBOM here – Consumer Electronic (Fortune 500) Company Turns To OpenBOM to Support Agile New Product Development, Improve Collaboration and Purchasing Process

Since implementing OpenBOM our Company has seen significant improvements in a number of areas. Specifically, the amount of hours spent just servicing BOM changes.

And here is a huge time saver…

“This time last year I personally spent 5 hours per week on BOM maintenance. It’s now 10 minutes a week. We see that same improvement with many of the lead engineers on the team. OpenBOM frees the team to do the other things that are important.”

How OpenBOM Can Help?

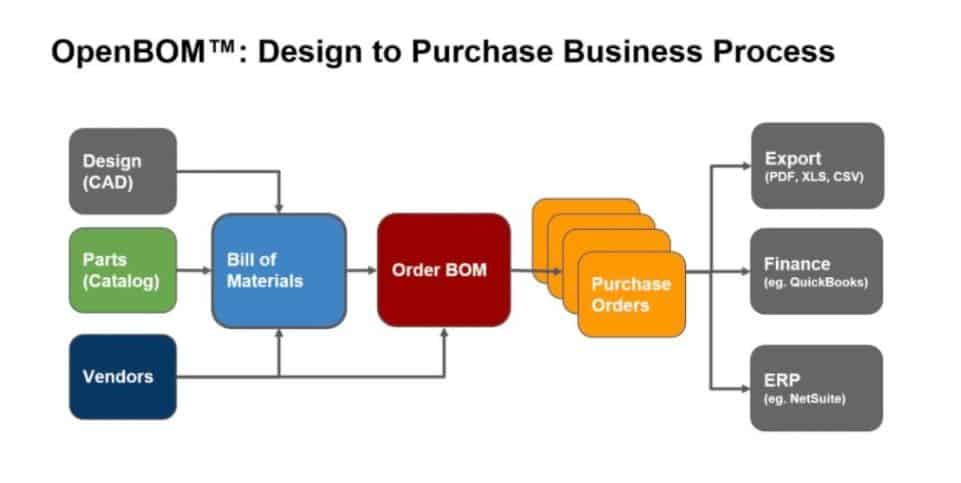

The way we designed OpenBOM is to focus on how to bridge the bottlenecks of siloed product development. The reality is many companies are stuck in silo thinking and we at OpenBOM developed the technology and a process to connect people and data by establishing an integrated information flow. Integration is a priority of manufacturing companies’ demand. And to have a good process integration between engineering and manufacturing is always a challenge.

OpenBOM connects engineers, production planners, procurement, contractors, and suppliers. At OpenBOM, we wanted to create a unique platform capable of providing integration between engineering production and procurement.

Here are 3 elements that make OpenBOM valuable to companies and teams looking to integrate the PLM+ERP process:

- Flexible Data Model capable of managing item master and information combined with product structure (Bill of Materials) with multiple views

- Deep engineering system integrations capable of seamlessly integrating with CAD and other systems used in product design and development

- Integrated production and purchasing planning capabilities which allow basic inventory control and procurement planning.

OpenBOM developed a unique support for OpenBOM Design To Purchase process, which can be used by new product development agile teams to achieve the high speed of product development and prototype production activity and it is integrated Production Planning and Inventory Control.Customer Experience Speaks for itself

Check out OpenBOM customer’s stories and online reviews on G2 Crowd where customers speak about how important it is to have an integrated way to organize the information flow and to run the company business using OpenBOM.

Here is what John Ellerbrock, California-based Gates Underwater Products, the manufacturer of the world-class underwater photography equipment says about their OpenBOM experience – Gates Underwater Products Uses OpenBOM To Connect Design Engineers, Manufacturing and Supply Chain Teams Together.

OpenBOM is our single source of truth,” says John. “ We have one location for parts catalog, COGS, inventory management, and assembly BOMs. All in OpenBOM, which has an intuitive and easy-to-navigate interface. Creation and update of BOMs are driven from within the Solidworks environment, so the link is always preserved and synced. Someone purchasing can open the BOM in OpenBOM and see the exact product and know what to buy.”

“We are moving steadily toward running the business on OpenBOM. It just works the way we want it to work. Naturally, and as a long-established company, we have a large backlog of existing products so migration to OpenBOM takes a systematic approach. In the end, we will have a fully digital representation of our products in Solidworks and OpenBOM”

Conclusion

Faster, better, cheaper. While these things are always true for manufacturing companies, the devil is in the details.

How to streamline the process, organize the information flow and connect people working together in a modern manufacturing environment? There is no simple answer to this question and companies are struggling to find a solution.

Thanks to modern technology and development in data management, SaaS, and modern user experience, OpenBOM can offer an integrated solution capable of capturing information, to share it with your team, contractors and suppliers to achieve the goals of agile product development.

OpenBOM’s patented collaboration technology provides unmatched support in the way a large group of people in distributed teams can work together.

When it comes to speed, PLM and ERP legacy solutions are too big to serve agile product development and manufacturing teams. OpenBOM brings a combination of SaaS platforms together with CAD integrations, engineering BOM, inventory management, and procurements. However, size doesn’t always matter. We can see the demand for such solutions coming from agile teams focusing on new product development in large industrial companies.

Check out what OpenBOM can do for you today – REGISTER FOR FREE and start a FREE 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.