Managing Engineering Bills of Materials (EBOM) is far more than simply exporting a drawing BOM to Excel. In OpenBOM, EBOM management comes with advanced capabilities designed to enhance efficiency, streamline workflows, and improve data organization. From attaching derivative files like STEP, STL, and PDF, to transforming CAD structures with Purchased Assemblies and Phantom Assemblies, OpenBOM empowers engineering and manufacturing teams with intelligent tools that save time and improve accuracy.

Let’s explore these advanced capabilities and see how OpenBOM can transform your EBOM workflow.

Why EBOM is More Than an Export of Your Drawing BOM

Traditional methods of managing an EBOM often involve exporting a drawing BOM to a static Excel file. However, this approach limits your ability to include rich metadata, and derivative files, or restructure the BOM for manufacturing.

OpenBOM takes EBOM management to the next level by enabling you to:

- Attach and manage derivative files such as STEP, STL, and PDF for parts and assemblies.

- Transform CAD structures with advanced options for Purchased Assemblies and Phantom Assemblies.

- Seamlessly integrate these capabilities into your CAD workflow through intelligent OpenBOM add-ins.

These functions eliminate manual steps, improve accuracy, and ensure all critical data is captured and organized in one central system.

Derivative Files: Centralized Management of Critical Data

Derivative files such as STEP for assemblies, STL for 3D printing, and PDF for drawings are essential in modern product development workflows. OpenBOM simplifies the process of creating and managing these files, ensuring they are always accessible and connected to your items and BOMs.

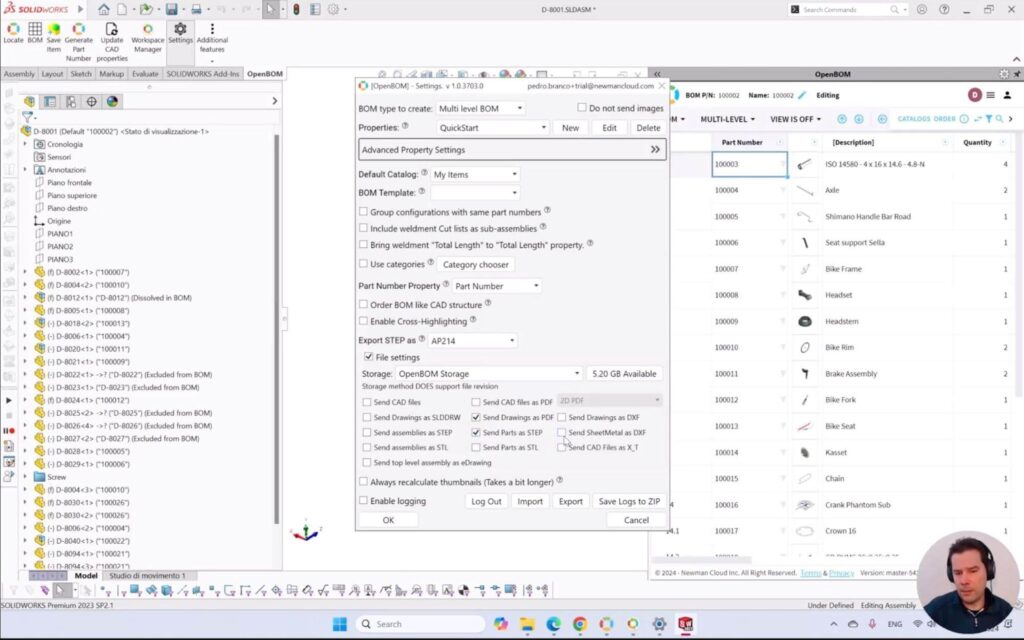

OpenBOM allows you to configure your CAD add-in settings to specify which derivative files should be automatically generated and saved. For example:

- Configure your CAD add-in to automatically create a STEP file for assemblies or a PDF for drawings.

- Set up the system to save these files to OpenBOM with every save operation, ensuring consistency and efficiency.

OpenBOM uses a unique References Property to store and link derivative files directly with Item and BOM records. This centralizes your data, making it easy to find and manage all related files in one place.

Here is an example of how to configure derivative files in SOLIDWORKS.

By automating and centralizing derivative file management, OpenBOM enhances collaboration and productivity while maintaining a clean digital thread.

🎥 Watch the video

Managing Phantoms and Purchased Assemblies

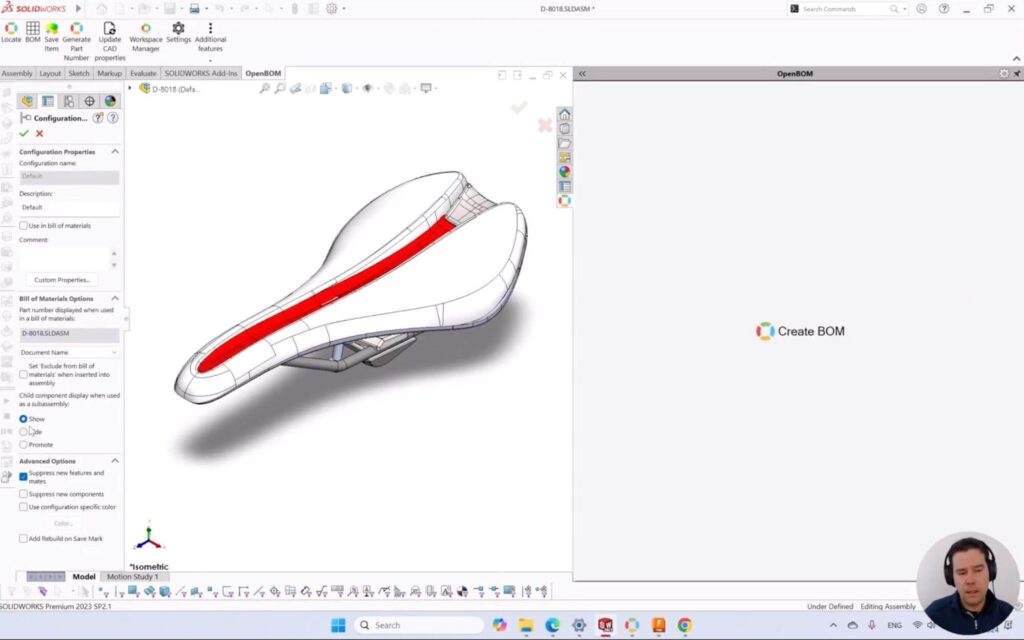

Transforming CAD structures to reflect manufacturing realities is a crucial part of EBOM management. OpenBOM provides robust tools for handling Phantom Assemblies and Purchased Assemblies, enabling you to tailor your BOMs to meet manufacturing and procurement needs.

- Phantom Assemblies

Phantom Assemblies are structures that are dissolved into their individual parts in the upper-level BOM. This is ideal for simplifying BOMs and reducing complexity for manufacturing. - Purchased Assemblies

Purchased Assemblies allow you to export the top-level assembly item without including its sub-parts. This is essential for scenarios where the assembly is procured as a single unit.

We provide step-by-step instructions for configuring both Phantom and Purchased Assemblies in popular CAD add-ins like SolidWorks, Onshape, and Autodesk Fusion. These settings can also be applied to other CAD integrations—reach out to our support team for further assistance.

Here is an example of configuring SOLIDWORKS:

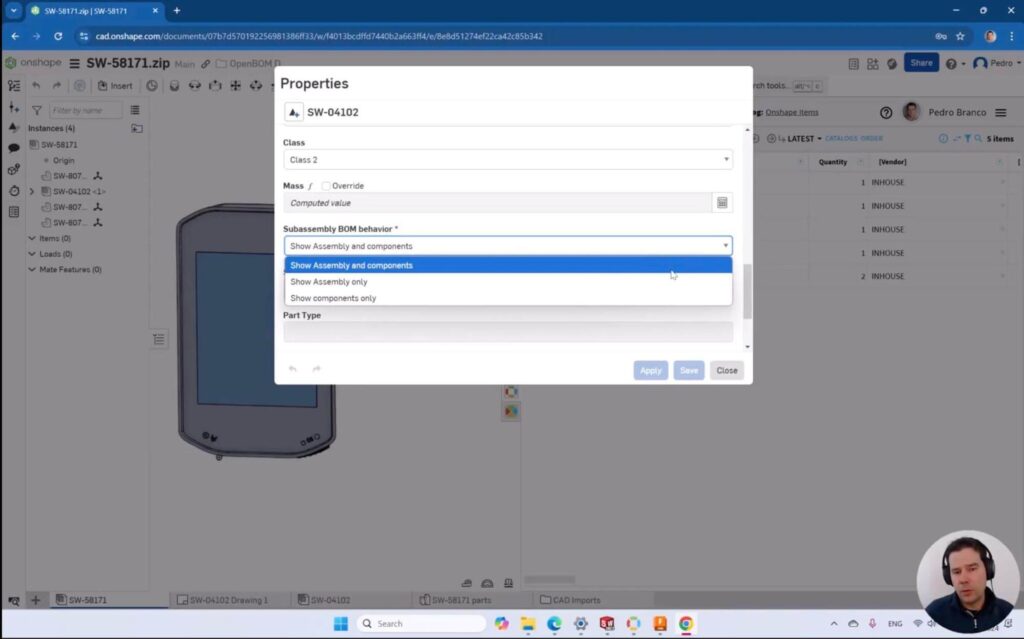

Here is an example of configuring Onshape:

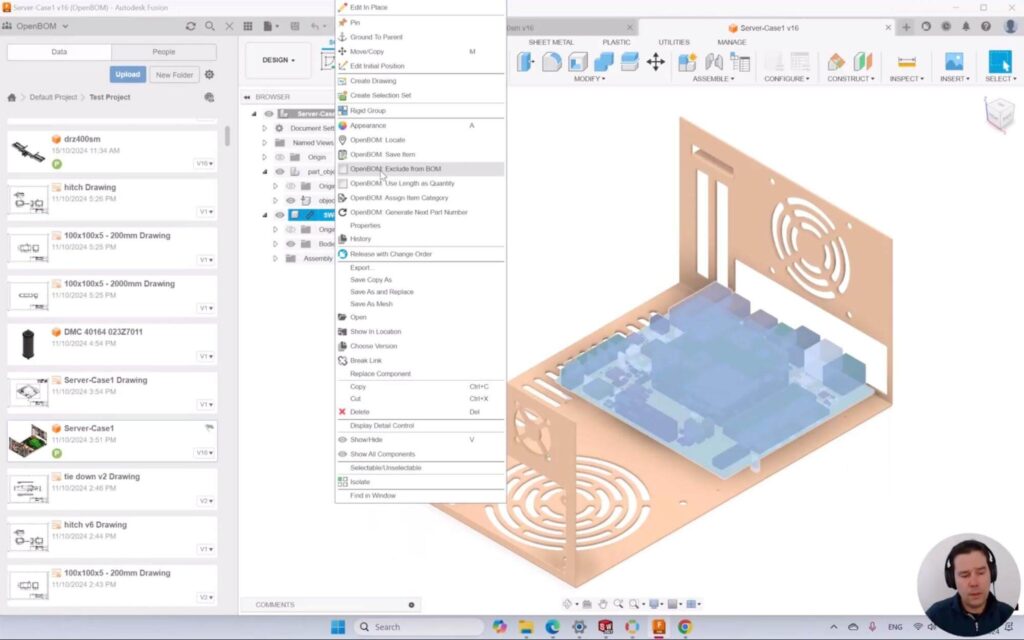

Here is an example of configuring Autodesk Fusion:

Managing Phantom and Purchased Assemblies ensures your BOMs are tailored for manufacturing, reducing errors and streamlining procurement.

🎥 Watch the video

Conclusion

OpenBOM’s advanced EBOM capabilities—derivative file management, Phantom Assemblies, and Purchased Assemblies—offer a comprehensive solution for modern BOM management. These features allow you to:

- Extract and organize all critical data and referenced files.

- Automate derivative file creation to save time and reduce manual work.

- Restructure your BOM to meet manufacturing and procurement requirements seamlessly.

By leveraging these tools, OpenBOM empowers your engineering and manufacturing teams to work smarter and collaborate more effectively.

Ready to explore these advanced EBOM features? Watch the videos, try it out, and see how OpenBOM can revolutionize your product data management!

REGISTER FOR FREE and start your journey with OpenBOM today!

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.