I’m excited to continue our “How-to” series of OpenBOM education. Today, we focus on Change Management. At OpenBOM we rethink change management and a traditional change process by introducing a collaborative workspace – the way to consolidate change processes happening in multiple systems and disciplines of the product (mechanical, electrical, electronics, and software).

Change management is a critical process for engineering and manufacturing teams. It involves managing updates to designs, product structures, and related data while ensuring accuracy, traceability, and collaboration. In this article, we’ll explore best practices for managing changes using OpenBOM, guiding you through the end-to-end change management process.

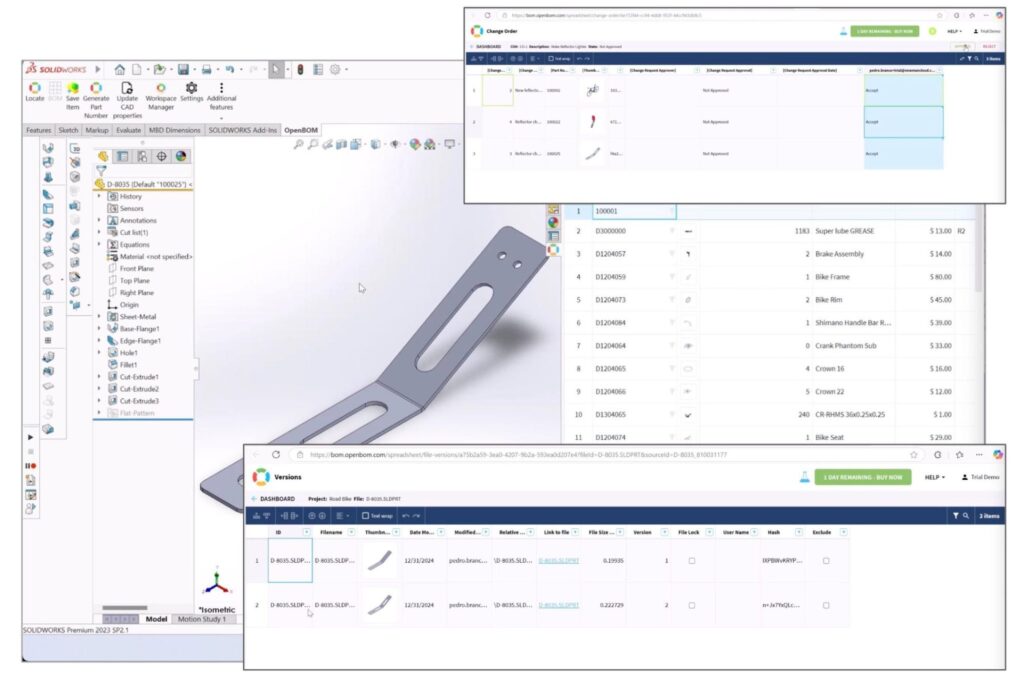

This guide is supported by four detailed how-to videos, each focused on a specific aspect of change management. Together, they showcase how OpenBOM simplifies the process with tools like design versioning, collaborative workspaces, and robust approval mechanisms.

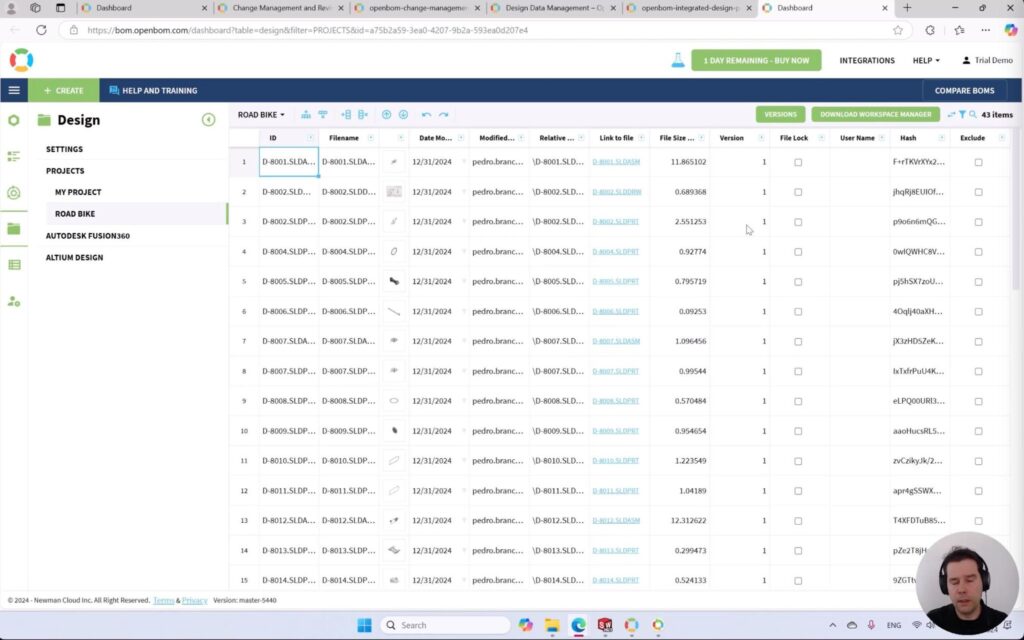

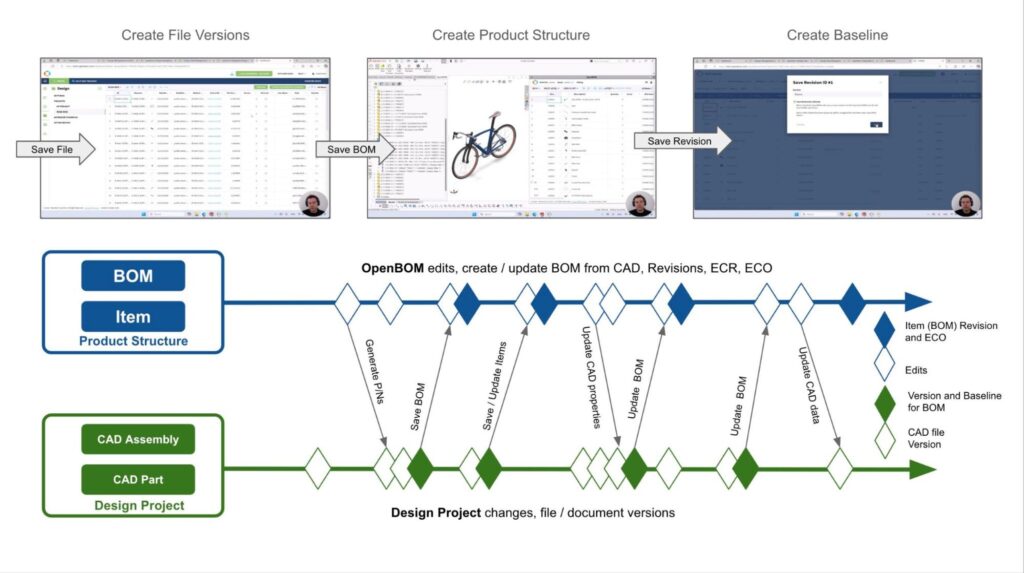

Design Versions, Item/BOM Create and Save Revision

The first step in effective change management is controlling design versions. This video demonstrates how to:

- Organize Design Projects for easy access and traceability of CAD files and other documents

- Create and manage CAD file versions in OpenBOM.

- Create initial Item/BOM product structure and

- Save Item Revisions

By mastering design versioning, teams can maintain control over evolving CAD data while keeping a clear record of changes.

The overall process can be illustrated as in the picture below shows you the main elements of data management by OpenBOM – CAD files, Items, BOMs as well as the interaction between these change processes.

Watch the video:

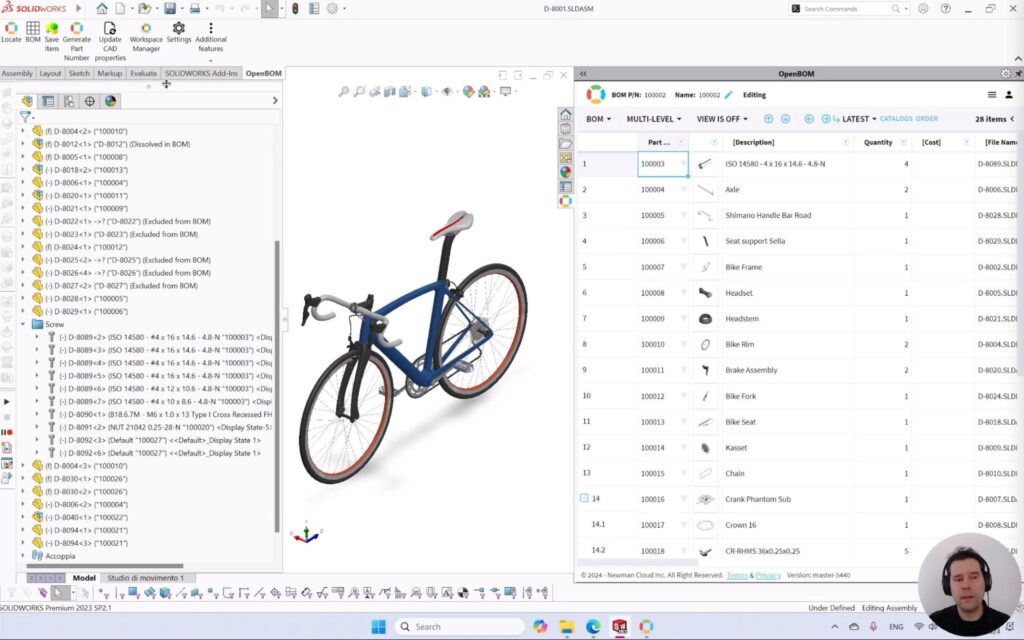

Update Information Between Item/BOM and CAD Files

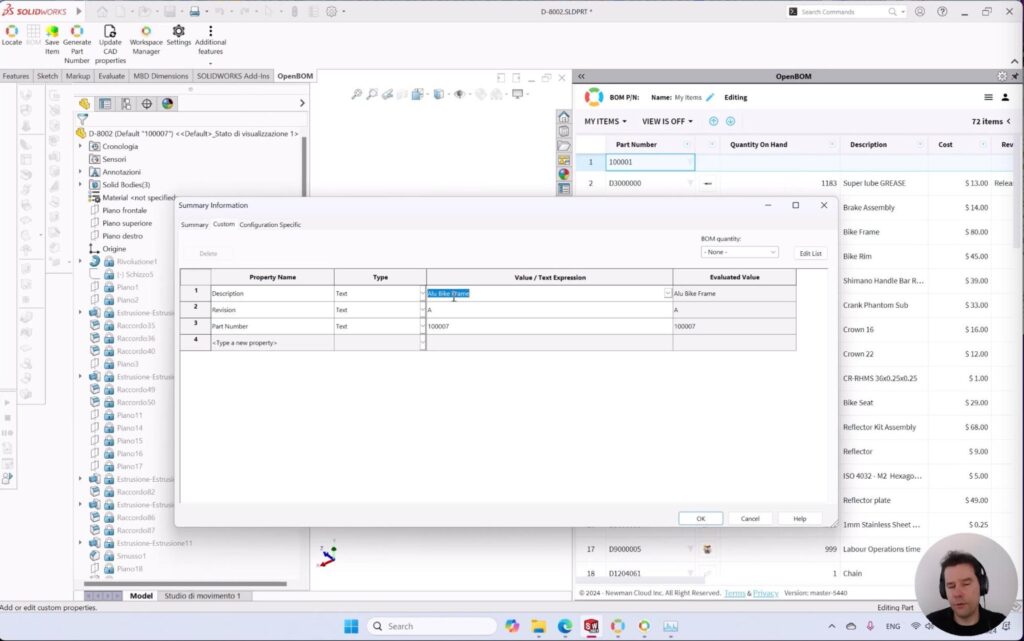

This video focuses on the integration between CAD data and product structure (Items/BOMs):

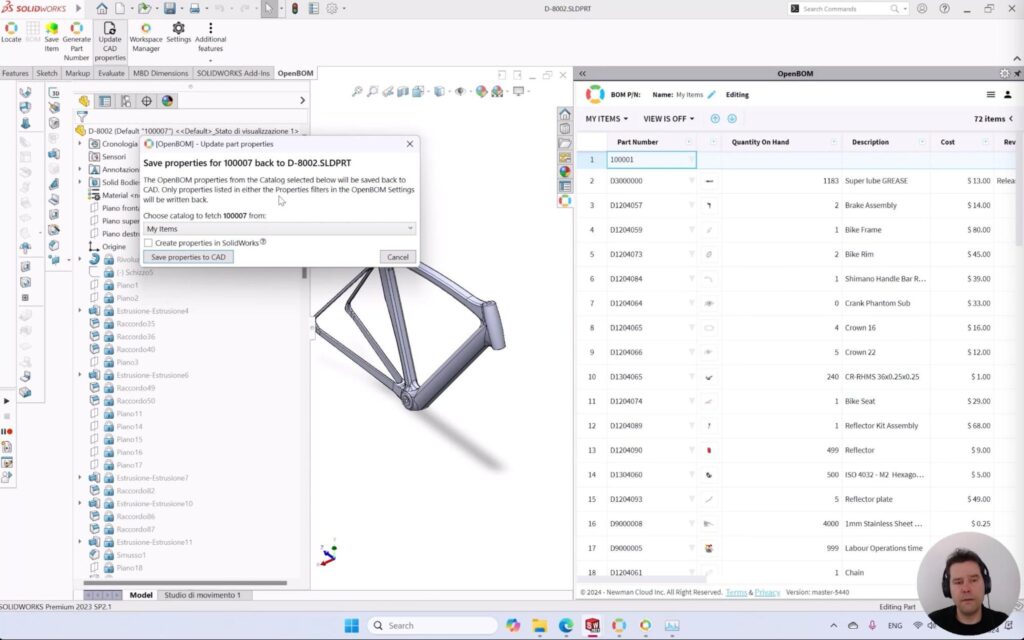

- Updating CAD attributes from item and BOM data to maintain data consistency.

- Synchronizing changes across CAD files, items, and BOMs.

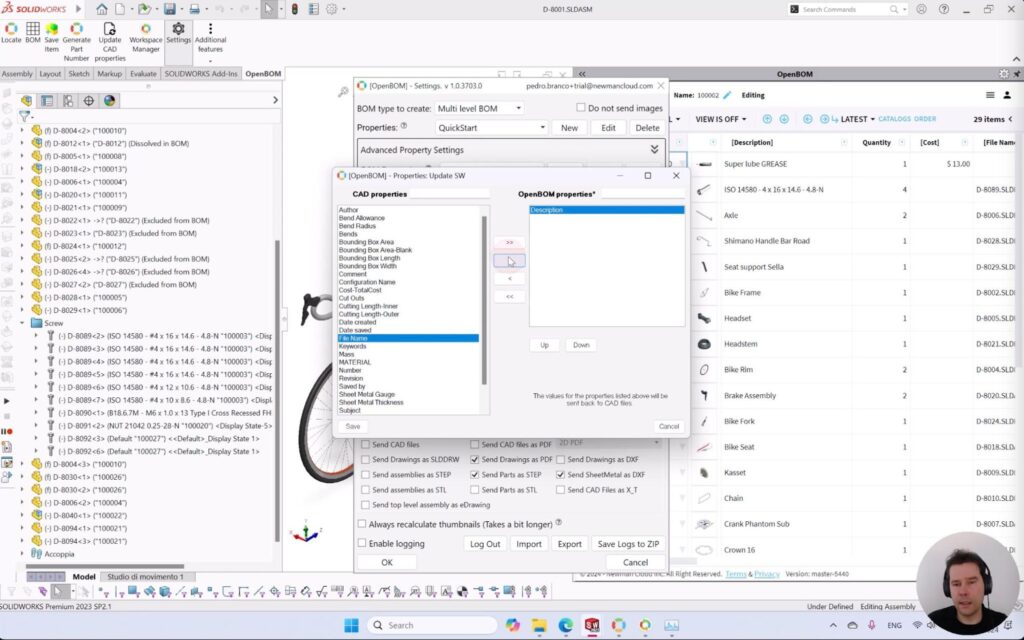

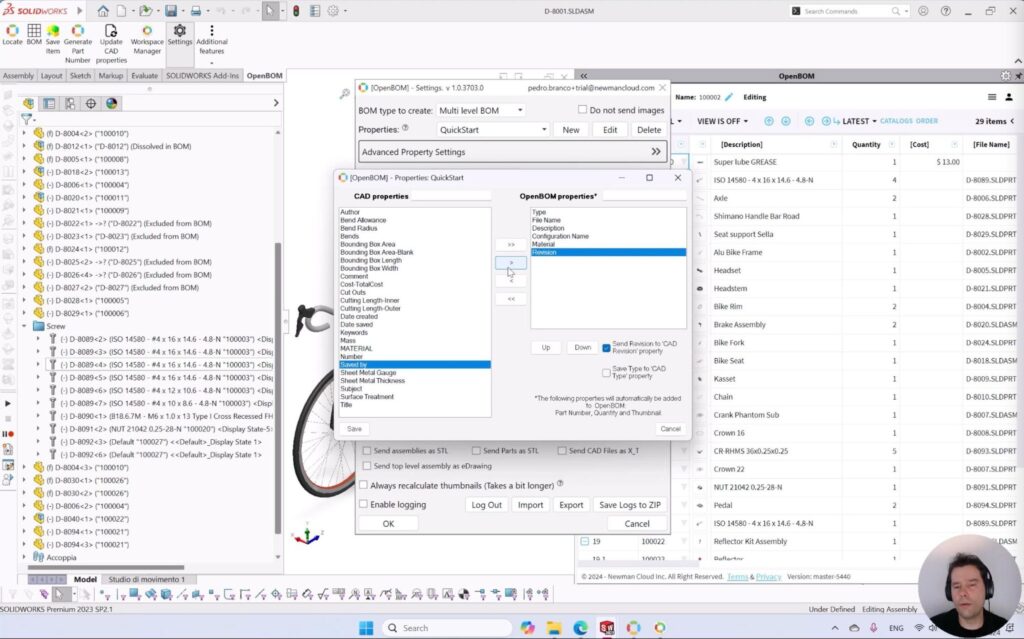

The first step in the process is to create a mapping between CAD data and Product Structure (Item/BOM)

Second to setup CAD attribute that will be connected to the Item data (in this case Description)

Last, but not least is the process of synchronization of data and pushing information from product structure and Items back to CAD files.

Efficient updates ensure that product data remains synchronized, reducing errors and improving collaboration between engineering and manufacturing teams.

Watch the video

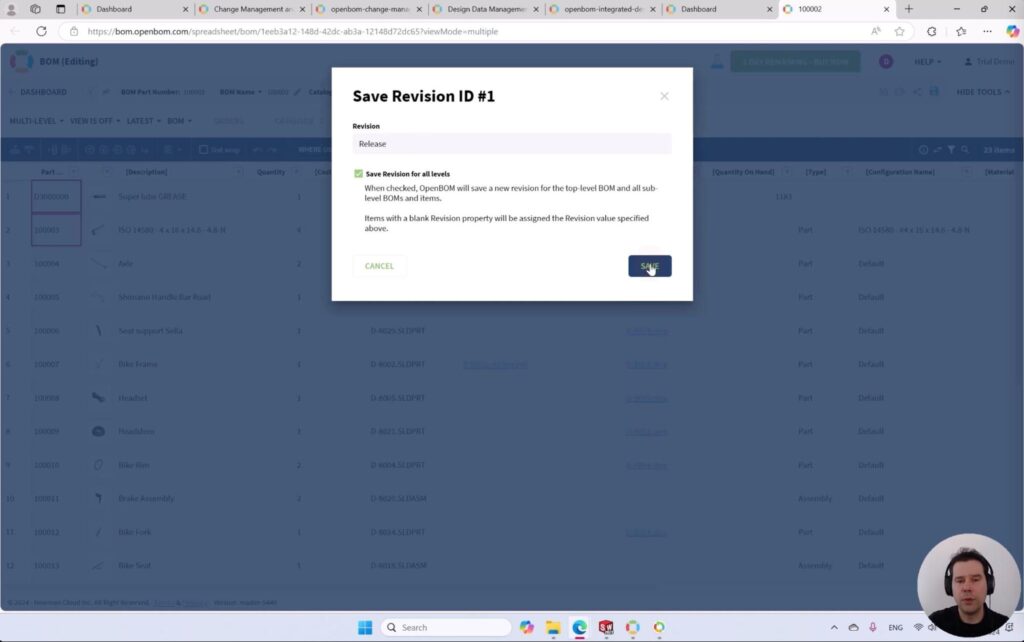

Initial Change Request: Collaborative Workspace and Revision Baseline

In this video, we dig into OpenBOM’s Collaborative Workspace, how it works and its role in enabling simultaneous updates by multiple users. Key topics include:

- Managing concurrent changes in CAD and non-CAD data across a shared workspace.

- Initiating a Change Request to capture and review proposed updates into an initial product structure (Items/BOMs) revisions.

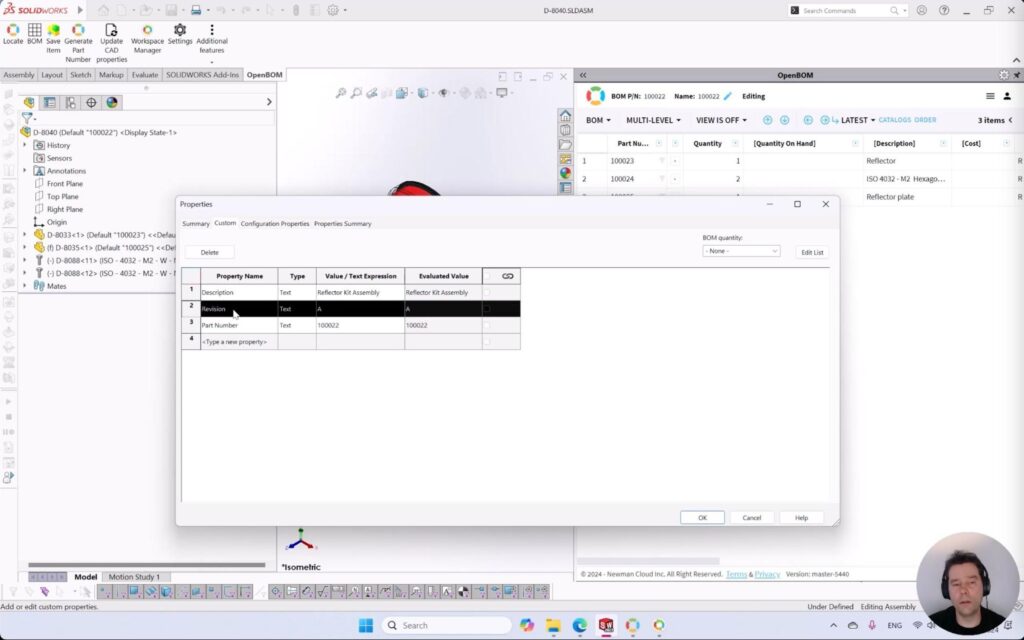

The first in the process is setting up CAD Revision setting to automatically add a revision attribute to an Item.

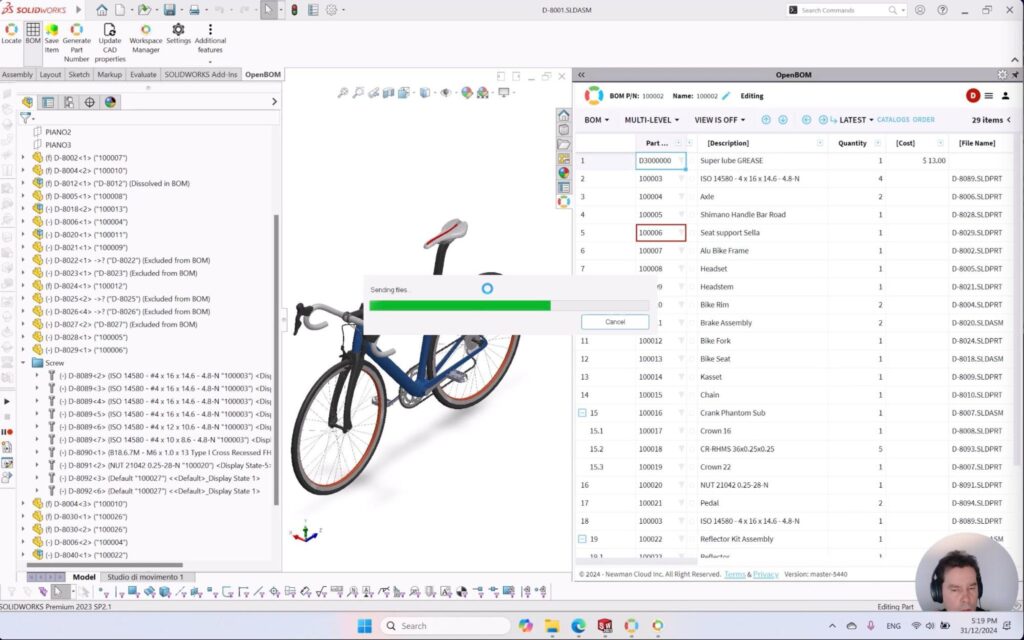

The data can be updated in parallel with both CAD-related data (eg sizes and geometrical parts) and some additional manufacturing information (supplier, non model items). Note – the data changes can be performed in parallel using the OpeBOM Collaborative Workspace process.

After the product structure has been created using the BOM command.

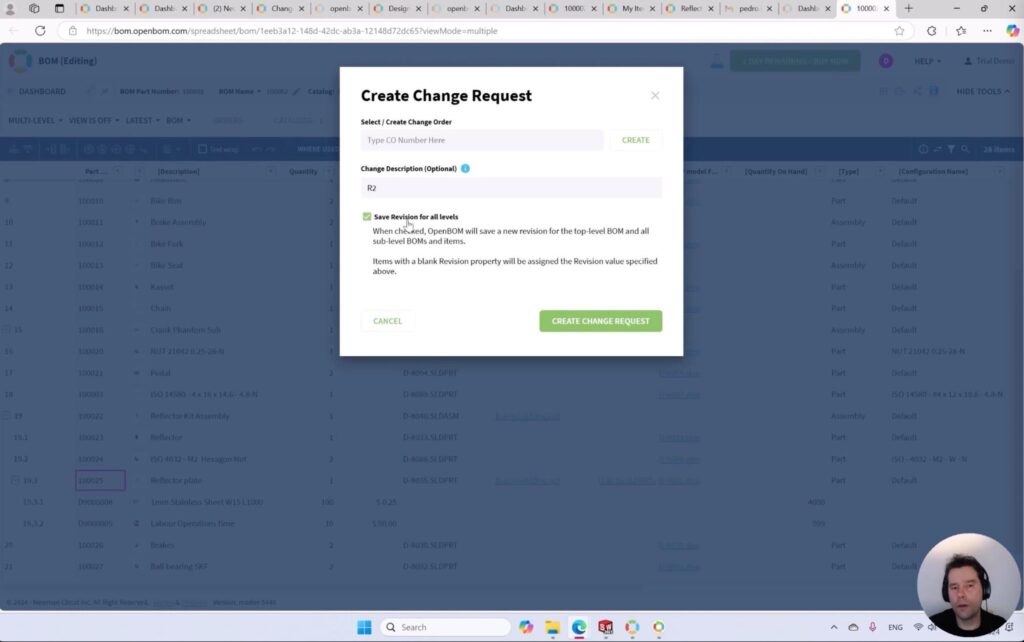

Once the entire data set is consolidated between CAD data and changes performed via collaborative workspace, the first revision is created using a change request.

This collaborative approach ensures that all team members can contribute efficiently while maintaining data integrity and traceability.

Watch the video:

Full Change Management Circle: Design Change, Product Structure Updates, and Change Order Approval

The final video ties everything together, demonstrating the full lifecycle of a change management process. This includes:

- Implementing design changes and saving updated file versions.

- Updating item and BOM data to reflect CAD changes.

- Initiating a Change Order and routing it through OpenBOM’s approval process.

This process ensures that every change is reviewed and approved, providing accountability and clarity in decision-making.

Watch the video:

Conclusion: Collaborative Workspace and Change Management with OpenBOM

OpenBOM is redefining change management with its innovative Collaborative Workspace and robust approval mechanisms. By enabling seamless collaboration, simultaneous updates, and collaborative approval workflows, OpenBOM empowers teams to manage changes effectively and confidently.

Through the four how-to videos and this guide, you’ll gain an understanding of how to handle changes in CAD designs, product structures, and perform change approvals. OpenBOM’s modern approach to change management accelerate change process, enhances collaboration, reduces errors, and improve your team’s efficiency.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.